(3486 products available)

1 4 x wire mesh plays a crucial role in various industries, offering a versatile solution for numerous applications. This product, made primarily from iron, is known for its strength, durability, and adaptability in different environments. 1 4 x wire mesh is commonly used in construction, agriculture, and industrial settings, providing essential support and security. Its unique properties make it suitable for fencing, reinforcement, and filtration purposes. As a staple in the metals and alloys category, 1 4 x wire mesh continues to be an indispensable material for projects requiring reliable and robust solutions.

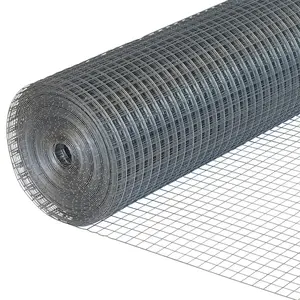

The market offers a diverse range of 1 4 x wire mesh, each designed to serve specific needs and applications. Some of the most common types include welded wire mesh, woven wire mesh, and expanded metal mesh. Welded wire mesh is formed by welding intersecting wires, providing a strong and rigid structure ideal for construction and fencing. Woven wire mesh, on the other hand, is made by interlacing wires in a crisscross pattern, which is perfect for filtration and sieving tasks. Expanded metal mesh involves cutting and stretching a sheet of metal to form a mesh, offering excellent strength-to-weight ratio and ventilation capabilities. Each type of 1 4 x wire mesh is engineered to meet particular requirements, ensuring optimal performance for its intended use.

1 4 x wire mesh serves multiple functions across different industries, thanks to its unique features. It provides structural support in construction projects, acting as reinforcement for concrete structures and retaining walls. In agricultural settings, 1 4 x wire mesh is used for fencing to keep livestock contained and protect crops from animals. It also serves as a barrier in industrial applications, ensuring safety and security by preventing unauthorized access. Key features of 1 4 x wire mesh include its corrosion resistance, high tensile strength, and flexibility. These attributes make it suitable for outdoor use and harsh environments, where durability and longevity are paramount.

The production of 1 4 x wire mesh involves the use of high-quality iron and, in some cases, additional materials to enhance its properties. Iron is the primary component, known for its strength and durability. To improve its resistance to rust and corrosion, 1 4 x wire mesh may be galvanized, coated with zinc to create a protective barrier against environmental elements. This process ensures that the mesh remains functional and maintains its structural integrity over time. In certain applications, stainless steel or other alloys may be used to provide additional benefits such as increased resistance to chemicals and extreme temperatures. The choice of materials in 1 4 x wire mesh production is crucial to ensure it meets the specific demands of its intended application.

Utilizing 1 4 x wire mesh effectively requires an understanding of its capabilities and limitations. When selecting the appropriate type of mesh, consider the specific requirements of your project, such as the level of strength needed or the environmental conditions it will face. For construction applications, ensure that the mesh is properly installed and secured to provide the necessary reinforcement. In agricultural or fencing applications, regular maintenance checks are essential to prevent wear and tear, ensuring the mesh continues to perform effectively. Additionally, consider the potential for customization and modification, as 1 4 x wire mesh can be cut, bent, or shaped to fit unique project specifications. Proper handling and installation will maximize the benefits of 1 4 x wire mesh, contributing to the success and longevity of your project.

When selecting 1 4 x wire mesh, it's essential to consider various factors that can impact its performance and suitability for specific applications. One of the primary considerations is the mesh size and gauge, which determine the strength and flexibility of the mesh. For construction projects requiring reinforcement, a thicker gauge and smaller mesh size may be ideal, while agricultural applications might benefit from a lighter gauge and larger mesh size for fencing purposes. Additionally, consider the environmental conditions the mesh will face, as exposure to moisture or chemicals may necessitate additional treatments, such as galvanization, to enhance durability.

Another critical aspect to consider is the material composition of the 1 4 x wire mesh. While iron is the primary component, variations such as galvanized iron wire mesh or stainless steel wire mesh can offer additional benefits. Galvanized mesh provides increased resistance to rust and corrosion, making it suitable for outdoor use, while stainless steel mesh offers enhanced strength and resistance to extreme temperatures and chemicals. Understanding the specific requirements of your project will help you choose the most appropriate material composition, ensuring optimal performance and longevity.

Mesh size significantly impacts the functionality of 1 4 x wire mesh. Smaller mesh sizes provide greater strength and support, making them ideal for reinforcement applications in construction. Larger mesh sizes offer increased flexibility and are suitable for uses such as fencing or filtration, where the ability to allow air or fluids to pass through is important. Selecting the right mesh size depends on the specific requirements of the application, balancing strength with desired permeability.

Galvanized 1 4 x wire mesh offers several advantages, primarily its enhanced resistance to rust and corrosion. The zinc coating applied during the galvanization process acts as a protective barrier, extending the mesh's lifespan in outdoor or wet environments. This makes galvanized mesh an excellent choice for agricultural fencing, construction reinforcement, and other applications exposed to harsh weather conditions. Additionally, the coating helps maintain the mesh's structural integrity over time.

Yes, 1 4 x wire mesh can be effectively used for filtration applications. Woven wire mesh, in particular, is suitable for sieving and filtering tasks due to its precise mesh openings. The mesh can separate particles based on size, making it ideal for industrial processes where filtration is required. When selecting mesh for filtration, it's crucial to consider the size of the particles to be filtered and choose a mesh with appropriate openings to achieve the desired results.

Maintaining 1 4 x wire mesh involves regular inspections to ensure its structural integrity and performance. For outdoor applications, it's important to check for signs of rust or corrosion, especially if the mesh is not galvanized. Cleaning the mesh to remove dirt and debris can help prolong its lifespan. Additionally, periodic checks for wear and tear, particularly in fencing applications, are crucial to ensure the mesh continues to provide effective support and security.

Customization options for 1 4 x wire mesh are available to suit specific project requirements. The mesh can be cut, bent, or shaped into various configurations, accommodating unique design needs. Custom mesh sizes and gauges can be produced to meet specific strength and flexibility requirements. Additionally, coatings or treatments such as powder coating can be applied to enhance aesthetic appeal or provide additional protection against environmental factors. Understanding the potential for customization allows for greater adaptability in diverse applications.