(124 products available)

The 10 barrel brewing system, also known as a 10-hl brewing system, usually includes the following core equipment:

Vessel:

A complete 10 bbl brewing system has 4 vessels, namely mash tun, wort kettle, lauter tun and hot liquor tank. They have different functions, such as cooking malt, boiling wort and storing hot water. Generally, the mash tun and boil kettle also function as each other during the brewing process.

Chiller:

A chiller is used to decrease the temperature of the wort to fermentation temperature rapidly. It prevents the wort from being contaminated. Different coolers include counterflow chillers, plate chillers, and immersion chillers.

Fermentation Vessel:

Also known as Fermentor, it's a vessel where the cooled wort is combined with yeast and fermented. The fermentation process usually takes 1~2 weeks and converts the wort into beer.

Kegging or bottling machine:

After fermentation, the beer will be packaged into kegs or bottles. The kegging and bottling process is automated for more efficiency. It includes filling, capping, labeling, etc.

In addition, there are several optional accessories and equipment for a 10-barrel brewing system, such as:

Grain Mill:

A grain mill is used to crush or mill the malt before it is added to the mash tun. The mill creates a coarse grain that allows water to flow through during the mashing process.

Pump:

Brewing systems have pumps for circulating the wort, transferring liquids between vessels, and controlling fluid flow during brewing, cooling, and packaging.

Filters:

They are used to separate liquids from solids, such as hops, malt, and yeast. Brewing system filters include keg, hop, beer, plate, and cross-flow filters.

Carbon dioxide tank:

It stores CO2 under pressure as a gas or liquid. CO2 is used to carbonate beer and purge kegs, lines, and tanks to prevent oxygen contamination.

Dehumidifier:

It extracts moisture from the air to reduce humidity. The device creates a more comfortable indoor environment and helps prevent mold and damage.

Oxygen tank:

An oxygen tank stores medical or industrial-grade oxygen. In brewing, oxygen can be used for certain processes, such as yeast propagation and growth.

Water Filter:

Filters are used to purify water by removing impurities, contaminants, and particles. It ensures the water quality used in brewing.

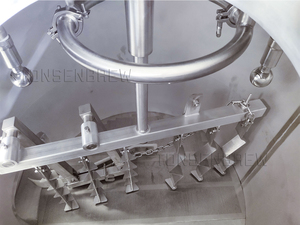

The CIP system:

CIP stands for Cleaning in Place. The system cleans and sanitizes the interior of brewing vessels and other equipment without disassembly.

Ingredients:

Key capacities:

10 BBL brewing systems are ideal for small to medium-sized breweries and are useful in various scenarios.

Start-up breweries

10 BBL brewing systems are ideal for new breweries because they provide sufficient capacity to meet market demands. Also, the cost of production is not too high, so the brewery can test different beer styles without breaking the bank.

Growing craft breweries

Breweries that are already established but still growing can benefit from a 10 barrel brewing system. This capacity allows them to increase production and meet the growing demand for their beers.

Test batches and experimental brews

10 barrel brewing systems are ideal for small-scale testing of new flavors and recipes. With this system, a brewery can easily adjust ingredients, brewing processes, and equipment to innovate and respond quickly.

Contract brewing and collaboration

10 BBL brewing systems are useful for contract brewing and collaborative projects with other breweries or enterprises. With this capacity, the brewery can produce beer for other companies on demand or engage in exciting collaborative projects.

Barrel aging and sour beer production

10 BBL brewing systems are useful for breweries that specialize in sour beers or those that want to experiment with barrel aging. These beer styles usually require longer fermentation times, and using a 10 BBL brewing system allows the brewery to set aside a portion of its barrel for these special brews.

Event and seasonal beer production

Breweries that need to create limited editions, seasonal, or special occasion beers can use a 10 barrel brewing system. These systems enable the brewery to brew smaller batches in a short period to meet the demands of festivals, holidays, or special events.

Public house and restaurant on-site brewing

10 BBL brewing systems are useful for restaurants and pub houses that want to brew their beer. The capacity is large enough to meet the needs of the restaurant, bar, or pub customers.

When choosing a 10 barrel brewing system for the best brewing needs, it is very important to look at all the factors that will enable an efficient brewing process. Important factors like brewery layout and workflow, energy source and efficiency, maintenance and support, brewing flexibility, equipment integration, scalability, staff training and brewery branding should be looked into.

It is very important to choose a brewing system that will fit into a brewery’s existing layout while also ensuring efficient workflow. The positioning of the brewery equipment should not have pipes crisscrossing all over, and there should be enough space for personnel to carry out their work with ease.

Breweries use different energy sources to brew beer. It could be electricity, natural gas or solar energy. It is very important to choose a brewing system with an energy source that will fit into a brewery’s existing energy source as this will positively influence brewing efficiency.

It is important to get a brewing system that is easy to maintain and with available support services. When the brewing system is easy to maintain, it ensures good beer is continually produced.

Choosing a brewing system that has the capability to use different beer recipes is essential. If the brewery intends to use different beer styles, it is important to get a system that has the capacity to research and use them all.

It is important to get a brewing system that can easily integrate with other equipment in the brewery. Whether this is fermentation tanks, kegs or packaging lines, a brewing system that integrates seamlessly will improve efficiency in operations and productivity.

If there are plans to expand or increase brewing capacity in the nearest future, it is important to choose a brewing system that will support the scalability needed for this expansion.

Though this may seem trivial, it is very important that the staff members who will be using the system are well trained. Choose a system that comes with adequate training resources and user-friendly interfaces.

Finally, the brewing system used will have a direct impact on the beer produced and how the brewery brand is perceived. Choose a system that shows good branding capabilities with custom labeling and logos. This will help the brewery stand out from the competition.

Q1: What is a 10-barrel brewing system?

A1: A 10-barrel brewing system refers to a set of equipment used to brew beer at a scale of 10 barrels per batch. One barrel is equivalent to 31 gallons or approximately 133 liters.

Q2: How much beer does a 10-barrel brewing system produce?

A2: A 10-barrel brewing system has the potential to produce up to 310 gallons or 1,304 liters of beer per year, assuming a brewing frequency of two batches per month.

Q3: What are the key components of a 10-barrel brewing system?

A3: The key components of a 10-barrel brewing system include a mash tun, boil kettle, fermenter, conditioning tank, heat exchanger, filtration system, and kegging or bottling line.

Q4: What are some advantages of 10-barrel brewing systems?

A4: 10-barrel brewing systems provide a good balance between small-scale and large-scale production. They offer sufficient flexibility to experiment with different beer styles while providing consistent brewing performance. Additionally, the equipment usually comes at a cost that many smaller breweries or startups can afford.

Q5: What are some challenges of 10-barrel brewing systems?

A5: 10-barrel brewing systems may not be suitable for very large-scale productions. Scaling up brews to larger volumes can be challenging. Additionally, the small-scale production nature may increase per-unit costs compared to larger-scale brewing systems.