(234 products available)

![[RTS]LS-252 Silicon Led Profile Aluminum Led Strip Housing <strong>Heatsink</strong> for Led](http://s.alicdn.com/@sc04/kf/H0a30d2ba306648c8a8f42889ae4f753fy.png_300x300.jpg)

A 1000mm heatsink is a component used in electronics to dissipate heat from high-temperature areas, such as CPUs or GPUs. It comes in various types, including:

Extruded heatsinks

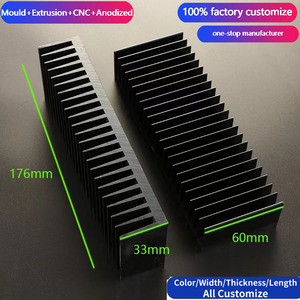

An extruded heatsink is a metal part that helps keep electronic devices cool by spreading and releasing heat from hot parts. They are made by pushing metal through a mold into shapes that are one long piece without any joints or seams. Most extruded heatsinks are made from aluminum because aluminum is a good heat conductor and not very heavy. The extrusion process works best with aluminum.

Extruded heatsinks come in different shapes and sizes for various uses. Even though they are made as one piece, the designs allow them to work well at cooling electronic parts that get very hot during use.

Folded Fin Heatsinks

A folded fin heatsink is a type of cooling device for electronics that has thin metal pieces, or "fins," that are bent into a zigzag shape. This helps the fins take up more space without being huge. More space is good because it allows heat to leave the heatsink into the air better.

Folded fin heatsinks work by spreading the heat from hot electronic parts into the air. As the air near the heatsink gets warm, it naturally moves up and away. Then cooler air comes in, allowing the folded fin heatsink to keep cooling the electronic parts that produce heat.

Welded Heatsink

A welded heatsink is a metal part that helps cool down electronic devices by transferring heat away from hot areas to prevent overheating. Welded heatsinks are made by permanently joining two pieces of metal together using heat from a welding machine. This creates a very strong bond between the metals.

Pinned Heatsink

Pinned heatsink is a cooling device for electronics that has a lot of small metal pins sticking out. These pins make the heatsink look like a porcupine. The pins give the heatsink more surface area to release heat into the air. Pined heatsinks work by spreading the heat from hot electronic parts into the air. As the air near the heatsink gets warm, it naturally moves up and away. Then cooler air comes in, allowing the pinned heatsink to keep cooling the electronic parts that produce heat.

Cooling Efficiency

Cooling efficiency is crucial in preventing components from overheating and maintaining optimal performance. This helps to prolong the lifespan of electronic devices and ensures reliability in their operations. Cooling efficiency is a fundamental factor in electronics.

Durability and Strength

The durability and strength of a 1000mm heatsink are vital because they ensure long-term reliability and consistent thermal performance. A strong heatsink can withstand different environmental challenges, like high temperatures, humidity, and physical impacts without degrading or losing its cooling capability. This durability guarantees that sensitive electronic components are protected from overheating, which can cause them to be damaged or fail.

Versatile Applications

A 1000mm heatsink is used in a wide range of industries and applications because of its durability and remarkable cooling characteristics. It is essential in the electronics industry and is found in LED lighting systems, computer processors, graphics cards, power electronics, and high-frequency transistors. It also ensures that the electronic components maintain optimal operating temperatures in renewable energy systems like solar inverters and electric vehicle batteries.

Material

The materials used to make a 1000mm heatsink significantly impact its effectiveness and efficiency. Aluminum and copper are the most widely used metals for heatsinks. Aluminum is lightweight and has good thermal conductivity, while copper has a higher thermal conductivity. Some heatsinks use a combination of metals to optimize cooling performance. The materials used can also affect the cost; aluminum heatsinks are generally more affordable than copper heatsinks.

Passive and Active Cooling

Active cooling heatsinks have components like fans or pumps that circulate coolant, providing more efficient cooling. In contrast, passive cooling heatsinks rely on the natural convection of air or liquid to dissipate heat. The choice between passive and active cooling depends on the application requirements, such as noise levels, power consumption, and cooling capacity. Heatsinks for high-power applications often use a combination of passive and active cooling methods.

A 1000mm heatsink is used in various industries and applications to dissipate heat from electronic components. Here are some common usage scenarios:

Power Electronics

Power Transistors: Long heatsinks are commonly used to cool power transistors in amplifiers and RF transmitters. They help dissipate the heat generated during high-power amplification or transmission, preventing transistor failure.

High-Power LED Arrays: Heatsinks are used to cool high-power LED arrays in lighting applications. They help maintain optimal LED performance and longevity by dissipating heat generated during illumination.

Computing and Data Centers

CPU and GPU Cooling: In high-performance computing systems, long heatsinks are utilized to cool central processing units (CPUs) and graphics processing units (GPUs). They are especially useful in data centers and servers where efficient heat dissipation is crucial to maintaining optimal operating temperatures.

Server Farms: In large server farms, long heatsinks are employed to cool densely packed servers. The extended surface area of the heatsink allows for efficient passive or active cooling, reducing energy consumption and operating costs.

Consumer Electronics

Audio Amplifiers: Long heatsinks are commonly used in audio amplifiers to dissipate heat from power transistors or MOSFETs. This ensures reliable operation and prevents thermal shutdown in high-output audio applications.

Graphics Cards: High-performance graphics cards used in gaming and professional applications often incorporate long heatsinks with attached fans to dissipate heat generated during intense graphics processing.

Industrial Machinery

Motor Controllers: Long heatsinks are used to cool motor controllers in industrial machinery, robotics, and electric vehicles. This ensures efficient operation and prolongs the lifespan of motor control components.

Renewable Energy

Inverter Cooling: In solar power systems and wind energy installations, long heatsinks are employed to cool inverters that convert DC to AC power. Efficient heat dissipation is essential for inverter reliability and energy conversion efficiency.

Telecommunications

Base Station Equipment: Long heatsinks are used to cool power amplifiers and other components in telecommunications base stations. This ensures reliable signal transmission and reception in wireless communication networks.

Automotive Electronics

Long heatsinks are utilized to cool various automotive electronic components, including power converters, battery management systems, and high-intensity discharge (HID) headlights. Efficient heat dissipation is crucial for the reliable operation of these systems in vehicles.

Aerospace and Defense

Long heatsinks are used to cool avionics, radar systems, and other electronic components in aerospace and defense applications. These heatsinks are designed to withstand harsh environments and operate at high altitudes.

Choosing the right heatsink requires careful consideration of several factors. Products should be selected based on the following criteria:

Size and Space Availability

The size of the heatsink is an important factor to consider. A large heatsink with big cooling fins is usually more efficient than a smaller one. However, large heatsinks may not be suitable for all designs because of limited space. When choosing a heatsink, consider the available space to ensure it will fit into the intended design or system.

Material

The material used to make a heatsink affects how well it cools. Copper heatsinks are usually better at dissipating heat than aluminum ones. However, copper is heavier and more expensive than aluminum. For applications where weight and cost are more important, aluminum heatsinks are a good choice.

Performance

The main function of a heatsink is to dissipate heat from the electronic component or LED Light. Heatsinks with good thermal performance should be able to dissipate heat efficiently. When choosing a heatsink, look for technical details like thermal resistance and dissipation efficiency. A heatsink with low thermal resistance will transfer heat more efficiently.

Compatibility

The heatsink should be compatible with the electronic device. Consider factors like the size, shape, and mounting options of the heatsink. Also, check if the heatsink can be connected to the LED or electronic device without blocking other components or causing interference.

Fan or No Fan

Some heatsinks come with fans, while others don't. Heatsinks with fans provide active cooling and are more efficient at dissipating heat. However, fan-based heatsinks make noise and require power. Heatsinks without fans offer passive cooling. They are quieter and use less power.

Cost

When choosing a heatsink, consider the cost. Copper heatsinks are more efficient but more expensive. Aluminum heatsinks are affordable and suitable for most applications where weight matters.

Q1: What are the common materials for 1000mm heatsink manufacturing?

A1: The most common materials are copper and aluminum. The two materials are known for their thermal conductivity ability. Copper is more conductive than aluminum but is usually more expensive and heavier. On the other hand, aluminum is lightweight, less costly, and sufficiently conductive. Most manufacturers use aluminum for large heatsinks due to its lower weight and cost.

Q2: What are the common challenges in 1000mm heatsink production?

A2: One of the main challenges is ensuring consistent quality and thermal performance. Another challenge is balancing cost and efficiency. This is the case because buyers want competitively priced products without compromising quality.

Q3: How to choose the right 1000mm heatsink for a particular application?

A3: Consider several factors, such as the size, material, and thermal performance. Also, consider the type of cooling solution. Choose a heatsink that meets the device's needs and is compatible with the device's design.

Q4: What is the typical lifespan of a 1000mm heatsink?

A4: Heatsinks can last as long as the lifespan of the electronic device they serve. This is usually between 10 and 15 years. However, this is only possible if the heatsink is made of quality materials and is properly maintained.