(686 products available)

160 micron nylon filter mesh is available in various types, each designed to meet specific filtration needs in different industrial settings. Here are some of them:

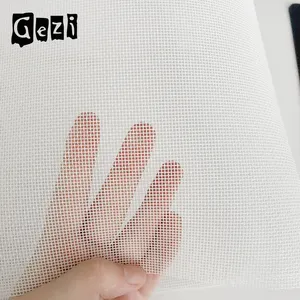

Woven Filter Mesh

Using specific nylon fibers, the 160 micron nylon woven filter mesh is manufactured so that yarns make up a grid pattern. It is then coated to enhance durability and resist chemicals. This filter mesh is more tear-resistant and has better filtering performance than those that have not been coated. It can be used for oil filtration, air filtration, and water filtration where impurities are not smaller than 160 microns.

Extruded Filter Mesh

Using an extrusion molding process, the 160 micron extruded nylon filter mesh is made in a fixed size and shape. It is generally more rigid than woven filter mesh. This type of filter mesh is suited for applications that require a consistent flow rate and have lower deformation under pressure than woven filter mesh.

Knitted Filter Mesh

The 160 micron knitted nylon filter mesh is manufactured through a knitting process that involves interlacing nylon fibers in a pattern. This type of filter mesh generally has greater elasticity and a three-dimensional structure, allowing it to catch more impurities. It has good filtration efficiency and is often used in the medical and food and beverage industries.

Spiral Filter Mesh

This type of filter mesh is manufactured by spiraling together nylon fibers. It boasts excellent filtration capabilities and is widely used in water treatment and chemical processing industries. According to research, spiral filter mesh works better in flow channels and has less blockage than knitted filter mesh. However, the production cost is higher than that of knitted filter mesh.

The following table summarizes important specifications and details about the filter mesh:

Mesh size

It is the number of holes per unit length. For example, a mesh size of 160 means there are 160 holes in one inch. Higher numbers mean more holes and finer filtration.

Filtration level

A filter mesh with a mesh size of 160 microns means its holes measure 160 microns across. This mesh can trap particles larger than 160 microns, allowing smaller substances to pass through.

Material

160 nylon filter mesh is made from nylon, a strong plastic thread that can withstand high temperatures and pressures and has good chemical resistance. Between monofilament and multifilament, the mesh is typically manufactured with monofilament, which provides higher stability and chemical resistance.

Product life

When used according to recommendations, 160 nylon filter meshes will last for many years. The exact life depends on the substance being filtered, the frequency of use, and the cleaning processes in between uses.

Though 160 nylon filter meshes are very durable, they still need some basic maintenance to function optimally. Regular maintenance extends the filter mesh's life and cuts costs for replacement filters.

Clean frequently

The most basic maintenance step is to clean it after each use. If the filter is not cleaned, residue will dry on it, clogging the mesh and reducing its ability to filter.

Cleaning methods

The method of cleaning a filter mesh depends on the substance caught in the mesh and its filtration level. Users can often rinse the mesh with water or compressed air. For used 160 nylon mesh filters, users can first try backwashing, which is a more effective cleaning technique. If backwashing proves ineffective, they can wash the filter manually, which involves submerging the filter in a cleaning solution and gently agitating the solution to help break up any remaining debris.

Users should be more careful with those that need high filtration levels. The particles might lodge more firmly in the mesh. For this type of filter mesh, lavage as a cleaning technique might damage its structure. The best option might be backwashing, which is more superior, safer, and more effective than others.

Deep clean

After many uses, some dirt might keep clinging to the filter mesh. Then, a deep cleaning process is required. Deep cleaning usually involves soaking the filter mesh in a cleaning solution that dissolves the substance being filtered. Use deep cleaning as a last resort because it shortens the filter's lifespan.

The 160 micron nylon filter mesh has many applications in industries and households. Here are some common usage scenarios:

Liquid Filtration

The 160 micron nylon filter mesh finds widespread use in various industries for liquid filtration purposes. It serves as an efficient filter to strain and remove particles from liquids of differing viscosities. Be it within the food and beverage, pharmaceutical, or chemical industries, incorporating the filter mesh into the filtration system improves product quality by safeguarding end products against contaminants.

Breathable Barrier

Because of its excellent airflow permeability, the 160 micron nylon filter mesh is frequently utilized as a breathable barrier. This occurs when the filter mesh is employed in the medical and health fields to make custom respirators, wound dressings, and other medical equipment. Here, the filter mesh enables unobstructed gas transfer (optimized regulation), thus offering patients optimal comfort and protection.

Strainer

Filter mesh with 160 micron openings is useful when straining liquids or semi-solids like puree in food preparation. It acts as an effective, reusable strainer for preparing nut milk, clarified butter, stock, and other foods. Using it for this purpose lets one achieve a smooth, consistent liquid and reduce exposure to single-use plastics.

Drying Rack

When sheets of the filter mesh are stacked up, they can be used to form a makeshift drying rack. Such a rack can be used to dehydrate fruits and vegetables, dry herbs, or even make homemade beef jerky. It's a low-cost, easy-to-customize use of the filter mesh for everyday food-drying needs.

Aerosol and Spray Filter

In the automotive and chemical industries, the 160 micron nylon filter mesh is frequently used to create aerosol and spray filters. It makes it possible for propellant gas to flow freely while effectively trapping liquid or mist particles. The filter's performance is better as equipment life is improved and operational costs are lowered.

Research and Laboratory Use

In research and laboratory settings, the 160 nylon filter mesh is used for sample preparation, cell line cultivation, and plate filtration, among other things. Its use in such contexts enhances experimental integrity by making sample isolation and purification processes efficient and quick.

Choosing the right 160 nylon filter mesh is essential to ensure optimal performance in the intended application. When selecting filter mesh, the following factors should be considered:

Mesh Count

The number of holes in a square inch is referred to as mesh count. Selecting the right mesh count is important because it determines the filter's flow rate and filtration level. Deciding on the right mesh count involves knowing the required filtration level and flow rate for the intended application. Some applications require a high level of filtration, while others need a greater flow rate. Once the filtration level and flow rate is known, selecting the appropriate mesh count to meet the requirements is easy.

Hole Size

The size of the holes in the mesh determines how much liquid or gas passes through. Choosing the right hole size is crucial because it impacts the filter's filtration level. Knowing the applications need makes it easy to select the appropriate hole size. For example, a biology lab may require a filter mesh with small holes to prevent bacteria from passing through. On the other hand, a wastewater management system may use a filter mesh with larger holes to allow more liquid to pass through.

Q1: What does the micron size mean for filter mesh?

A1: Micron is short for micrometer, which is a unit of measurement equal to one-millionth of a meter. In filter mesh, the micron size indicates the mesh's hole or pore size. A smaller micron value means finer mesh, which captures smaller particles.

Q2: Is nylon filter mesh better than other materials?

A2: Nylon filter mesh has a lot of benefits. It is flexible and can be used in applications that require a mesh to bend. Another benefit of nylon mesh is its chemical resistance, which allows it to filter substances like oils, solvents, and chemicals without degrading. Nylon mesh can also tolerate heat and drying techniques used in the food and beverage industry.

Q3: Does the filter mesh's micron size affect the flow rate?

A3: Yes, it does. A mesh with larger pores lets more liquid or air pass through. However, a coarse mesh may let through unwanted particles. Finding the right balance between the flow rate and filtering the required particles is important.