(693 products available)

22mm MR MDF

Manufacturers create moisture-resistant (MR) MDF to be used in areas that are exposed to high humidity, such as kitchens and bathrooms. This type of 22mm MDF sheet is ideal for these conditions because it has a green resin exterior that increases durability and moisture tolerance.

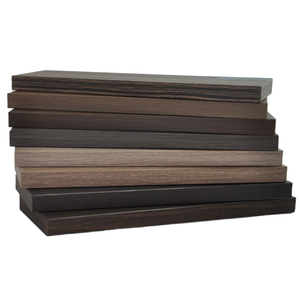

22mm veneered MDF

Veneered MDF integrates the sturdiness of MDF with the aesthetic appeal of natural wood veneers. The veneer layers give the MDF an attractive wood-like finish for quality, which is convenient for making laminated furniture and interior design components.

22mm High-Density Fibreboard

HDF is referred to as high-density made of fibres arranged in a dense structure that gives it more strength and a smooth texture compared to normal MDF. Construction industry experts recommend this type of material for surface applications such as 22mm mdf boards for precise machining, painting, or veneering.

22mm ULDF

ULDF also comes with a lower density compared to regular MDF. This makes it lighter but still versatile for several uses. It is appropriate for applications where weight is important and where moderate durability is required.

22mm Laminated MDF

Manufacturers create laminated MDF by applying a laminate layer to its surface. This improves the board's appearance and resistance to scratches and moisture. Using 22mm Laminated MDF is useful for decorative surfaces and furniture construction.

22mm Acoustic MDF

Acoustic MDF has sound-absorbing properties and was created for applications requiring acoustic control, such as music studios and audio-visual rooms. It helps reduce noise levels effectively while still providing a solid surface.

Following the correct maintenance process increases the 22mm MDF sheet's life and looks. Maintenance consists of the following processes:

Cleaning

Use a damp cloth to regularly dust MDF sheets gently. The user should avoid soaking the surface, which can warp the material. For tough stains, a mild soap-and-water mix should do the trick. Do not use abrasive cleaners or scouring pads, as they can damage the surface.

Sealing and Coating

If possible, sealing MDF with paint, veneer, or laminate is key. Sealing prevents moisture from entering the material, which can cause swelling and deformation. Regularly inspect the finish and re-apply paint or varnish when it starts looking worn.

Temperature Control

Keep MDF sheets away from direct sunlight and sources of intense heat. Extreme changes in temperature can cause the material to warp. Store unused sheets in a cool, dry place and cover them to avoid moisture infiltration and dust accumulation.

Drilling and Cutting

Use specialized blades for cutting MDF. This gives smooth edges and prevents the board from breaking. Always wear a mask and work in a ventilated environment during the cutting of MDF. It generates fine dust that may be harmful when inhaled.

Storage

The 22mm MDF sheet should be horizontal and even on a flat surface to prevent bowing or bending. When placing multiple sheets on top of each other, ensure they are properly aligned to avoid unnecessary pressure on any one sheet.

Furniture Manufacturing

22mm MDF sheets have widespread usage in furniture making, especially for creating cabinet doors, shelves, and table surfaces. Their smooth, flat surfaces make them ideal for applying finishes, laminination, or painting. This gives aesthetically appealing and very durable pieces of furniture.

Interior Design

22mm MDF sheets are generally fit for interior design applications such as decorative panels, wall coverings, and moldings. Their versatility allows designers to accurately create intricately detailed designs to give a modern and elegant appearance to interiors.

Cabinetry

The 22mm MDF wood sheet has a common application in modern kitchens and wardrobes. The board provides a sturdy and level base for cabinet construction. Its size and thickness make it good for heavy loads and prolonged everyday usage.

Doors and Panels

Cabinet and interior doors use 22mm MDF sheets for their increased stability and non-warping characteristic. The material can be shaped into flat-panel doors, which can later be painted or veneered for a sleek and polished finish.

Signage

The 22mm MDF sheets provide an average density that is ideal for creation of custom interior signage. Its surface enables detailed engraving and painting, which makes it popular for retail environments, exhibitions, and indoor advertising purposes.

Sound Insulation

Manufacturers create acoustic panels with the 22mm MDF sheets that help reduce sound transmission. The thickness and density of the material make it effective in absorbing sound and hence frequently using it in recording studios, theaters, and media rooms.

DIY Projects

MDF sheets are also popular materials among do-it-yourself enthusiasts. They help create customized shelves, photo frames, or wall art since they can be cut easily and give a smooth finish after cutting. The 22mm MDF sheet is strong and very versatile for creative projects around the home.

The 22mm MDF sheets meet various international quality standards. These ensure that they can be used reliably across numerous applications:

22mm MDF sheets come with adequate safety considerations for their use and handling:

Handling Precautions

MDF sheets should always be handled with care for their thickness and weight, especially doing it carefully not to snap or bend. Always wear protective gear like gloves and masks when cutting or sanding to avoid inhaling fine dust particles that can be harmful to health.

Work Area Ventilation

Make sure that the working area is properly ventilated, especially when cutting, sanding, or drilling, since it releases fine dust into the air. Use a dust mask or respirator while working with MDF to reduce fine particle inhalation that can affect the lungs and general health.

Proper Equipment

Always use tools with proper adherence to safety and efficiency. Blades intended for cutting MDF guarantee minimal tearing and fine dust generation. A reduction in dust generation means a reduction in health risks associated with MDF.

Dust Collection

Using saw with attached dust collection systems can aid in cutting and sanding processes. These systems minimize the particles released into the air and improve the air quality in the work area.

Disposal of MDF Dust

MDF sanding dust contains formaldehyde and other chemicals, making it unsafe for disposal without necessary precautions. Collect all the dust generated and dispose of it in accordance with local regulations regarding hazardous materials.

A1. The MDF board price usually varies greatly with factors like thickness, density, and origin. Another consideration is the local market and international sourcing. Prices also differ by seller specials and overall board demand. Buyers can always check with local suppliers for more specific and current prices.

A2. MDF sheets are not recommended for outdoor utilization since they tend to absorb moisture and warp. The only condition in which they can be used safely outdoors is when they get constant protection from moisture and weather conditions. This could be a waterproof finish or a covered shelter, but even those measures only extend their lives by some time. For outdoor furniture, manufacturers prefer plywood or other materials that endure weather elements.

A3. Use masking tape placed on the cut line. It holds the fibers and reduces chipping when cutting. The use of a fine-toothed saw blade designed specifically for MDF also minimizes chipping. A table saw with an MDF fence also gives a smooth cut. One more thing is to score the cut line with a sharp utility knife. This helps in a chip-free cut.

A4. The medium density fibreboard sheet is partially recyclable since it's made of wood fibers glued together under pressure and heat. While it is a challenge to fully recycle MDF due to the adhesive used in its production, some facilities can still break it down for reusing the wood fibers in new engineered board products. So, yes, while challenging, recycling is quite possible with the right techniques.

A5. Simply applying a coat of paint, varnish, or a plastic laminate goes a long way in preventing the MDF from absorbing moisture. These barriers reduce moisture absorption and help keep the board intact. Edge banding on exposed edges also goes a long way in preventing moisture absorption.