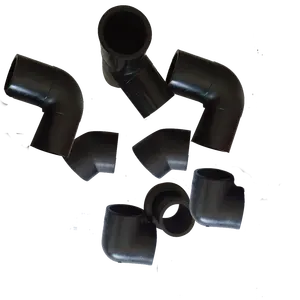

Introduction to 24 Pipe Fitting Elbow

The 24 pipe fitting elbow is an essential component commonly used in plumbing, HVAC systems, and various industrial applications. This type of elbow fitting is designed to connect two lengths of pipe while allowing for a directional change, typically at a specified angle, such as 90 degrees or 45 degrees. With its unique shape, the 24 pipe fitting elbow ensures minimal resistance, facilitating the smooth flow of liquids and gases through the piping system.

Types of 24 Pipe Fitting Elbow

The varieties of 24 pipe fitting elbows primarily differ based on their material composition, angles, and connection types:

- Materials:

- Stainless Steel: Known for its corrosion resistance and durability.

- PVC: Lightweight and easy to install, suitable for non-pressure applications.

- Brass: Highly durable and offers excellent resistance to corrosion.

- Iron: Traditionally used for heavy-duty applications requiring strength.

- Angle Types:

- 90-Degree Elbow: The most common type for creating sharp turns.

- 45-Degree Elbow: Ideal for gentle directional changes.

- Connection Types:

- Threaded: Provides a secure fit with easy installation.

- Socket Weld: For a strong, permanent connection.

- Solder Joint: Used in copper piping systems.

Applications of 24 Pipe Fitting Elbow

The 24 pipe fitting elbow is versatile and widely used across various sectors, including:

- Plumbing:

- Connecting plumbing pipes in residential and commercial buildings.

- Facilitating changes in pipe direction to optimize space usage.

- HVAC Systems:

- Routing air ducts for efficient ventilation.

- Handling refrigerant lines with minimal pressure loss.

- Industrial Applications:

- Transporting fluids in manufacturing plants.

- Working in chemical processing systems requiring a high-performance fit.

Advantages of Using 24 Pipe Fitting Elbow

Opting for a 24 pipe fitting elbow presents numerous advantages that enhance both functionality and installation. Here are some notable benefits:

- Easy Installation: Most elbow fittings are designed for quick and straightforward installation, reducing labor time.

- Increased Flow Efficiency: The design minimizes turbulence and resistance, leading to enhanced flow rates.

- Durability: Made from high-quality materials, these fittings are resistant to wear, leak, and impact over time.

- Versatile Compatibility: Available in various materials and sizes, allowing compatibility with most standard piping systems.

- Chemical Resistance: Certain materials like PVC and stainless steel offer strong resistance to corrosion, making them suitable for harsh environments.