(378 products available)

A 300mm heatsink comes in different types depending on the application. Below are some common types:

Air-cooled heatsinks

This is the most popular type of heatsink. It uses passive or active cooling methods to dissipate heat. An air-cooled heatsink relies on air to cool down while removing heat from the component. An air-cooled heatsink is less expensive and simple to install. Also, it is suitable for smaller electronic devices that generate less heat.

Liquid-cooled heatsinks

This heatsink cools down by using liquid. It consists of a pump, coolant, and radiator. The pump circulates the coolant through the heatsink. The coolant absorbs heat from the component and transfers it to the radiator. Here, the heat is dissipated. Liquid-cooled heatsinks are more efficient than air-cooled ones. They are used in high-performance CPUs and GPUs.

Passive heatsinks

These heatsinks are not connected to any power source. They cool down by natural convection. Passive heatsinks are made with materials that can conduct heat well. They are essential in applications where components generate less heat.

Active heatsinks

These heatsinks have a built-in fan. The fan provides forced convection that cools down the component effectively. Active heatsinks require external power to operate. They are used in applications that generate more heat.

Heat pipe-based heatsinks

These heatsinks use heat pipes to transfer heat quickly. The heat pipes are sealed and contain a working fluid. When the pipe gets hot, the fluid inside evaporates and moves to cooler regions. The heat is dissipated here, and the fluid condenses back to liquid. Heat pipe-based heatsinks are very efficient. They are used in laptops and high-performance computing devices.

Fin-based heatsinks

These heatsinks have many thin metal strips (fins) attached to the base. The base is in contact with the hot component. As air flows over the fins, heat is dissipated. Fin-based heatsinks are simple and inexpensive. They are good for small electronic devices that do not generate a lot of heat.

Heatsinks are used in a variety of electronic devices and applications. Heatsinks play an important role in thermal regulation, maintaining optimal operating temperatures for components and ensuring reliable performance and longevity in the following applications.

Thermal Dissipation

The primary function of a 300mm LED heatsink is to dissipate heat away from the electronic component it is attached to. This is done by transferring heat from the component to the surrounding air. The heatsink absorbs the heat through conduction and then releases it into the air through convection and radiation. The larger the Heatsink, the more effectively this is done. The heatsink keeps the electronic component at a safe operating temperature by dissipating heat. This prevents overheating and damage to sensitive parts. It ensures the component can function reliably and with a longer lifespan.

Material

Heatsinks are made of materials with a high thermal conductivity, allowing heat to spread quickly and efficiently dissipate into the air. Common materials used include aluminum and copper. Some heatsinks are made of a combination of aluminum and copper to leverage the strengths of both materials. Aluminum is lightweight and can be made into complex shapes, while copper has superior thermal conductivity. The most common material is aluminum due to its good performance and low weight. This makes aluminum heatsinks easy to handle and cost-effective. Aluminum heatsinks are also less prone to corrosion. Copper heatsinks are used in applications that demand higher heat dissipation. They are compact and efficient.

Design and Construction

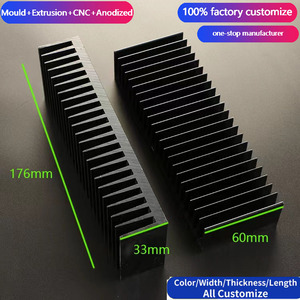

The design of 300mm heatsinks is based on the principle of increasing surface area to promote heat dissipation. They are constructed with multiple thin fins or louvers arranged in a pattern. This creates a large surface area for heat to escape into the air. The open structure design allows air to flow freely through the heatsink and around the fins. This enhances cooling by convection. Some heatsinks have fans that blow air over the fins to increase the airflow speed. This makes heat dissipate faster. The Heatsink's surface is often anodized or painted with a matte black finish. This absorbs heat better and increases radiation cooling.

300 mm heatsinks are widely used in various electronic devices and applications. Some common uses include:

Power Amplifiers

Heatsinks are used in RF and audio power amplifiers. For instance, in high-power transmitters, audio power amplifiers for home theaters, and professional sound systems. They help maintain the transistors' or amplifiers' optimal operating temperatures, thus improving their performance. Additionally, they enhance their reliability by dissipating heat generated during operation.

High-Power LED Lighting

LED lighting systems, particularly those using high-power LEDs for commercial and industrial applications, employ heatsinks. Such systems include; LED floodlights, streetlights, and task lighting. Heatsinks ensure the LEDs maintain their efficiency, brightness, and lifespan by managing heat dissipation.

Industrial Machinery

Heatsinks are used in various types of industrial machinery. For example, in heavy equipment, manufacturing machinery, and process automation systems. They help cool down components such as motors, drives, and control electronics. This ensures uninterrupted and reliable operation of the machinery, reducing the risk of overheating and subsequent failures.

Power Electronics

Heatsinks are widely used in devices like; thyristors, IGBTs (Insulated Gate Bipolar Transistors), MOSFETs, and power converters. They help manage the heat generated during switching and conduction operations. This allows for continuous operation and improves the efficiency and reliability of the devices.

Graphics Cards

High-performance graphics processing units (GPUs) used in gaming, video rendering, and scientific computing applications rely on heatsinks. The reason being they dissipate heat generated during intense computations. This prevents thermal throttling and enhances optimal GPU performance, thereby enabling smooth rendering of graphics and computations.

CPUs and Motherboards

Central Processing Units (CPUs) in computers and other devices use large heatsinks. These include fans or other cooling solutions to dissipate heat generated during computation. This prevents overheating and allows for sustained high-performance computing. Additionally, it allows for efficient multitasking and resource-intensive applications.

Server Racks

In data centers and server farms, large-scale server racks incorporate heatsinks. These systems dissipate heat from multiple servers and networking equipment in a compact space. This ensures optimal performance and reliability of the servers, thus minimizing downtime. Additionally, it allows for continuous operation in high-density computing environments.

Choosing the right 300mm LED aluminum heatsink for a specific application involves considering several factors. Here are some key factors buyers need to take into account before purchasing.

Size and Compatibility

Buyers should ensure that the LED aluminum heatsink dimensions are compatible with their LED light fixture design. They should consider factors like space constraints and mounting options. Heatsinks come in different shapes and sizes. Therefore, it is important to select a heatsink that will fit well and perform efficiently.

Thermal Performance

Excellent thermal performance is a must for any reliable heatsink. Buyers should look for 300mm LED aluminum heatsinks with high thermal conductivity. They should also pay attention to the design features like fins to enhance heat dissipation. Some heatsinks come with fans for active cooling. Business owners should analyze the LED light's power consumption to determine the ideal thermal performance.

Weight and Stability

The weight of the heatsink can influence the stability of the entire lighting structure. This is more so when it comes to suspending or mounting systems. Business owners should choose a heatsink that strikes a balance between weight and thermal performance. This is important when dealing with limited support structures.

Manufacturing Quality

Business owners should select heatsinks from reputable manufacturers. They should inspect the construction quality of the heatsinks to ensure reliability and longevity. It is also important to consider the reviews and ratings of previous customers.

Ease of Installation

Business owners should look for heatsinks that are easy to install. Such heatsinks will reduce the overall installation time and costs. They can check the provided mounting solutions and installation instructions.

Q: What are the advantages of a 300mm heatsink?

A: A 300mm heatsink provides a larger surface area for heat dissipation, enabling more efficient cooling. This is especially important for high-powered components or in applications where overheating could damage the hardware. Moreover, larger heatsinks may require fewer fans, leading to quieter operation and reduced potential points of failure.

Q: What are the challenges of a 300mm heatsink?

A: While a 300mm heatsink provides efficient cooling, it also poses design challenges. Due to its size, it may be difficult to fit into compact electronic designs. Additionally, larger heatsinks are heavier, which could raise concerns about the stability of mounted components, especially in environments with vibrations or when the equipment is transported.

Q: How should a 300mm heatsink be maintained?

A: Heatsink maintenance involves regular cleaning and inspection. Over time, dust can accumulate on the heatsink and fans, reducing cooling efficiency. Use a soft brush or compressed air to remove dust from the heatsink fins and fans. Inspect the thermal paste periodically. It may need replacement if the heatsink is dismounted or as it dries out over time. Apply a thin, even layer of thermal paste to ensure proper heat transfer when reattaching the heatsink.

Q: Can a 300mm heatsink be used without a fan?

A: Yes, a 300mm heatsink can be used without a fan in passive cooling applications. However, this is only possible if the heatsink is sufficiently large to dissipate heat through natural convection. This is the process where warm air rises and is replaced by cooler air. A fan may also be omitted from the heatsink if the electronic device operates at low temperatures and power ratings.