(17591 products available)

Types of 3D PE foams

Different types of 3D PE foams are available for creating outstanding 3D designs for specific events and marketing campaigns. One of them is the heat transfer film. It is a preferred option because of its compactness, versatility, and low-cost production value. Using the heat transfer film essentially creates a design after applying heat and pressure to the foam film. Another common type is the adhesive films. These films work exceptionally well when a certain surface or material requires a unique design or pattern. What works well with adhesive films is the substrate, which could include wood, glass, ceramics, and more. However, the surface needs to be clean and dry for the film to adhere to it.

Blister packs are typically used to protect and display products. However, Foam 3D PE blisters can be used to fill any gaps and provide support during transit. This results in an additional 3D layer of protection.

Specifications of 3D PE foam pieces depend on the final product they are used to create. Typically, the specifications include the texture, width, and shape. OEMs can customize these features to create specific products. Usually, 3D PE foams come in thicknesses of from 1 mm to 50 mm. Wider dimensions can be achieved by gluing two or more layers together.

3D PE foam is very easy to maintain compared to other types of cushioning. In most cases, a wet cloth is enough to clean its surface. Use mild detergent when necessary and avoid bleach to prevent damaging the texture of the foam. If the dirt is too stubborn, immerse the cloth with some water and wipe it down with detergent. To dry, use a dry, clean cloth to absorb excess water. It is crucial to ensure that the 3D PE foam piece is thoroughly dried to avoid mold and mildew growth.

Like any other type of foam, 3D PE should be stored in a cool and dry place, away from direct sunlight. Avoid stacking heavy items on top of it, as this will change its shape and result in uneven cushioning.

3D PE foams are applicable in many industries. Here are some common usage areas where 3D PE foams are useful.

Signage and Advertising

3D PE foams are great for creating eye-catching signage, logos, and promotional displays. Their lightweight nature allows for easy installation, and they can be illuminated to enhance visibility and draw attention.

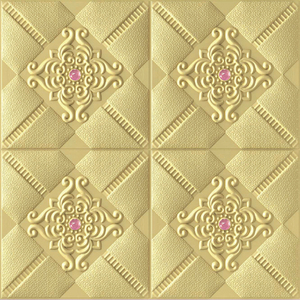

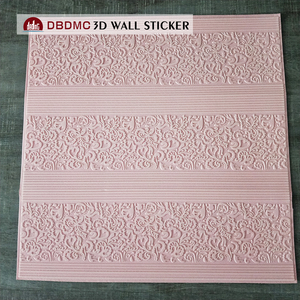

Architectural and Interior Design

The foam is useful for creating architectural features like columns, cornices, and ceiling medallions. They are affordable as compared to similar materials and are applicable for creating product mock-ups and full-scale architectural models.

Exhibitions and Trade Shows

3D PE foams create custom exhibit booths, trade show displays, and event backdrops that stand out. Using these materials ensures easy transportation, quick assembly, and adaptability to different booth sizes and layouts.

Retail Environment

3D PE foams can be used to create engaging retail environments such as pop-up shops, flagship stores, and in-store displays. The foams will enhance brand storytelling, attract foot traffic, and create an immersive shopping experience for customers.

Special Events and Themed Parties

One can use 3D PE foam props and decorations for weddings, birthday celebrations, corporate events, and more. Custom theme elements, focal points, and photo booth backdrops can be created with these materials.

Theater, Film, and Television Production

3D PE foams are great for building stage sets, scenic backdrops, and architectural elements for theatrical performances, films and music videos. The lightweight allows for easy manipulation and rapid assembly during production schedules.

Education and Training

3D PE foams are useful in specialized training simulations and educational programs. They can be used to create realistic scenarios, training aids, and hands-on learning tools in medical training, military simulations, and vocational education.

Transportation and Packaging

Protective packaging inserts, cushioning, and foam-layer padding for shipping containers and boxes can be made with 3D PE foams. The materials help to cushion and protect goods during transit, minimizing the risk of damage.

Choosing the appropriate 3D foam eggs for one's business is no small task. However, one can make a confident choice by considering a few factors.

Intended Use:

Decide on the application for the foam piece. Will it serve as a centerpiece, a decorative item, or a packaging solution? Distinguishing its purpose helps select a 3D foam shape that meets specific needs.

Size and Dimensions:

Consider the required size and dimensions of the foam shape. Different applications may need varying sizes, so it is essential to get one that fits the project's requirements.

Customizability:

If the project requires a unique design, it is best to go for 3D foam shapes that can be easily customized. Some suppliers offer options for businesses to request specific shapes, sizes, or colors to match their brand or project vision.

Quality and Durability:

Ensure to choose a supplier that provides high-quality and durable foam shapes. The quality of the foam can affect the final product's appearance and longevity.

Budget:

Consider the best 3D foam shapes that fit within budgetary constraints. It's essential to find a balance between quality and price while selecting the foam shape that meets the project's needs without overspending.

Supplier Options:

Research different suppliers offering 3D foam shapes and compare their options. Read reviews, check ratings, and ask for recommendations to find a reputable supplier that can meet specific requirements.

Order Quantity:

Determine the required order quantity of foam shapes based on project needs. Some suppliers may have minimum order quantities, so it is essential to consider the quantity needed for the specific project or upcoming demand.

Q1: How long will 3D PE foam products last?

A1: The longevity of an item made with 3D PE foam depends on many factors, like the type of foam used, how it was made, and how it's looked after. If looked after properly, 3D PE foam items can last many years even with regular use.

Q2: Can 3D PE foam withstand extreme temperatures?

A2: One of the great things about 3D PE foam is that it can be made to resist high and low temperatures. Special additives and treatments allow some types of 3D PE foam to work well in very hot or very cold places. However, most 3D PE foam materials are not suitable for extreme heat, like being near fire.

Q3: What are the environmental impacts of 3D PE foam?

A3: Making, using, and disposing of 3D PE foam can affect the environment. The production of 3D PE foam involves processes that may contribute to air pollution. If not reused, recycled, or disposed of properly, 3D PE foam products can add to the global waste crisis.

Q4: Does 3D PE foam have any health risks?

A4: Some types of foam may contain tiny amounts of chemicals that could affect health. However, risks linked to 3D PE foam are much lower than other materials, such as asbestos or lead. Still, people should reduce exposure by not inhaling dust or fumes from foams during cutting or sanding.

Q5: Are there any special requirements for transporting 3D PE foam products?

A5: Items made with 3D PE foam must be handled carefully. They should be packed well, cushioned, and secured to prevent damage during transport. They also need to be kept in a climate-controlled vehicle so that they don’t get too hot or too cold.