(382 products available)

A 400mm heatsink comes in different sizes and shapes. The types listed below are based on size, shape, and configuration.

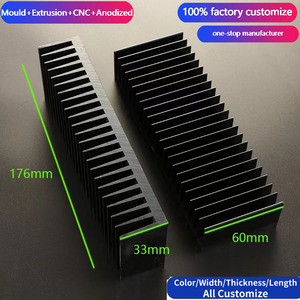

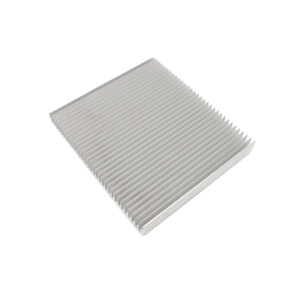

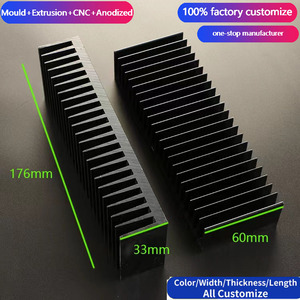

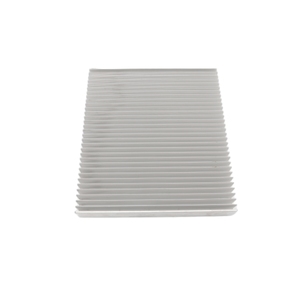

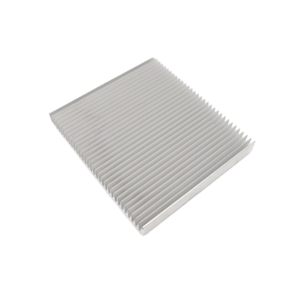

Extruded

These are the most common types. The heatsink is made from aluminum, which is light and affordable. It is used in applications where weight and cost are important. The extruded heatsink is made through the extrusion process. Aluminum is forced through a die that creates specific shapes. The process produces thin and long structures with high thermal conductivity. The extruded heatsink is made in different shapes and sizes. They can be square or rectangular. They can also have fins that increase surface area and improve cooling. The heatsink is popular because it is affordable and easy to produce. It can also be customized to fit specific applications.

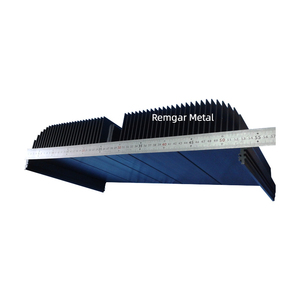

Folded Fin Heatsink

This heatsink has fins that are folded like a flower. The design looks complex, but it is made from aluminum that is affordable and light. The heatsink is made using a stamping process. This involves cutting and folding the aluminum to create fins that are welded on a base plate. The folded fin heatsink uses more aluminum than the extruded heatsink. However, it has a larger surface area for cooling. It is mainly used in cooling applications with high thermal power. The heatsink design is efficient because it minimizes airflow resistance. It is also more efficient than the extruded heatsink.

Skived Heatsink

This heatsink is made from solid aluminum or copper. The metal is shaped into fins through a skiving process. The process involves cutting the aluminum or copper to create fins that are attached to a base. The skiving process produces heatsinks with high aspect ratios. The skived heatsink provides a more direct path for heat dissipation. It is used in applications that require low thermal resistance. The heatsink is also lightweight. It is used in applications where weight is important. The skived heatsink has fewer joints and seams. This improves thermal conductivity.

Blob Heatsink

This heatsink has a large, thick aluminum or copper block. The block absorbs and spreads heat from the component. It is made by adding solder to create a ''blob'' on the component. The heatsink is then placed on the blob and heated to create a bond. The blob heatsink is important for cooling high-power components. It is also used in applications where thermal conductivity is important. The heatsink design is simple and effective. It can be made quickly and affordably.

Heatsinks function to dissipate heat from electronic components, allowing them to operate at safe temperatures. Some features include:

Size: The size of a heatsink plays a critical role in heat dissipation. A larger heatsink has more area and dissipates heat better. However, the size also affects the weight and space available. A 400mm heatsink is large and provides ample cooling to bigger systems, ensuring they function optimally.

Material: The material of a heatsink affects its ability to transfer heat from the component to the air. Materials like aluminum and copper are good at transferring heat. Aluminum is lightweight and cheaper, while copper is more efficient but heavier. A 400mm aluminum heatsink is prevalent since it strikes a good balance between cost and efficiency. Some advanced heatsinks use materials like graphite or carbon nanotubes.

Cooling capacity: A good heatsink should have high cooling capacity and remove heat efficiently. Cooling capacity is usually expressed in watts (W). The higher the cooling capacity, the better the heatsink dissipates heat. For example, a 400mm heatsink with a cooling capacity of 200 watts can be used for high-end CPUs or GPUs.

Design and configuration: The design and configuration of a heatsink affect its cooling efficiency. Designs like fin-based, flat-based, or circular-based provide different cooling capacities. A fin-based design is more efficient since it increases surface area. Other designs are compact and use space efficiently. The configuration also includes how the heatsink is mounted on the component.

Compatibility: Heatsinks are compatible with specific electronic components. It is essential to ensure that the heatsink is compatible with the device it is intended for. Compatibility determines how the heatsink is mounted and its cooling efficiency. Factors like socket type, size, and mounting mechanism should be considered when choosing a heatsink.

Weight: The weight of a heatsink affects its application. Heatsinks made of heavy materials are more robust and durable. At the same time, lighter heatsinks are more portable and convenient. Weight is also essential in computer systems, where parts like CPUs and GPUs can be fragile.

Price: The price of heatsinks varies depending on size, material, and brand. Larger heatsinks are more expensive since they use more material. Copper heatsinks are costlier than aluminum heatsinks. It is essential to consider the budget when choosing a heatsink, but one should not compromise quality.

When choosing a 400mm heatsink, several factors must be considered to ensure optimal performance for the intended application. Here are some key considerations:

Size and Form Factor

Heatsinks come in different sizes and shapes. Consider compact designs if space is limited. Larger heatsinks provide better cooling, but ensure they fit within the device's dimensions. Check the heatsink's dimensions, such as height, width, and depth, to avoid purchasing one that will be too large for the intended area.

Cooling Requirements

Assess the cooling needs based on the application. High-performance components may require robust heatsinks for efficient heat dissipation. Determine the amount of heat to be dissipated, usually measured in watts. Higher power requirements will necessitate larger or more efficient heatsinks.

Material

Look for materials with high thermal conductivity, such as copper or aluminum. Consider aluminum for a lighter solution or copper for superior heat transfer. Copper heatsinks are better for high-heat areas, while aluminum is lighter and sufficient for moderate cooling.

Mounting Options

Ensure the chosen heatsink can be securely mounted to the component. Common methods include screws, clips, or adhesive thermal pads. Check the socket or mounting mechanism of the CPU or GPU and choose a heatsink compatible with it. Some heatsinks require specific mounting hardware.

Fan/No Fan

Decide between passive (no fan) or active (with fan) cooling solutions. Passive heatsinks rely on natural convection and are quieter, while active heatsinks have fans for better cooling efficiency. A fan-equipped heatsink will provide more cooling, especially for high-performance parts. Without a fan, a heatsink must rely on natural airflow.

Check Compatibility

Ensure the heatsink is compatible with the hardware it will be used with. Consider socket type, mounting mechanism, and thermal interface material (TIM) application. Check the CPU or GPU specifications and choose a heatsink recommended for those components. Look at the thermal resistance and ensure it meets the cooling needs.

Ease of Installation

Consider how simple it will be to install the heatsink. Some may require special tools or skills, while others are user-friendly. Look for heatsinks with straightforward mounting procedures and clear instructions. If unsure, consult a professional for installation.

Q1. What are the most common materials for a 400mm heatsink?

A1. The two most common materials are aluminum and copper. While aluminum is lighter and less expensive, copper has a higher thermal conductivity, which allows it to dissipate heat more effectively. Some heatsinks are made of a combination of both copper and aluminum.

Q2. What are the most common sizes for heatsinks?

A2. Heatsinks come in different sizes and shapes depending on the application. For standard electronic applications, a 400mm x 400mm x 50mm size is common. However, there are many other sizes, including 300mm, 350mm, and 400mm. The size increases from 300mm to 400mm in 100mm increments.

Q3. What are the most common types of 400mm LED heatsink?

A3. The most common types include extruded, stamped, and machined heatsinks. Extruded heatsinks are made from aluminum and are popular because of their lightweight and cost-effective nature. Stamped heatsinks are made from aluminum sheets and are used in applications where weight is more important than cost. Machined heatsinks are made from copper and provide the best thermal performance, but they are also the most expensive.

Q4. What are the most common surface finishes for a heatsink?

A4. The most common surface finishes include Anodized, Black and Natural. Anodized heatsinks have a layer of aluminum oxide that protects them from corrosion and improves their thermal performance. Black anodized heatsinks are popular because black is a better color for dissipating heat. Natural anodized heatsinks are less common, but they are still used in some applications.

Q5. What are the most common ways to attach a heatsink to a chip?

A5. The most common ways include Adhesives, Thermal Pads, and Mounting Hardware. Adhesives provide a permanent bond between the heatsink and chip, while thermal pads provide a removable connection. Mounting hardware uses screws or clips to attach the heatsink to the chip and can be easily removed if necessary.