(1094 products available)

40hp chillers are industrial cooling systems that absorb heat from a liquid through a vapor-compression or absorption refrigeration cycle. They are also known as 40hp condenser chillers. These machines are suitable for large-scale commercial and industrial use.

40hp condenser chillers are classified into two primary types: air-cooled condensers and water-cooled condensers.

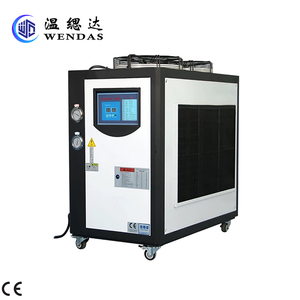

Air-cooled chiller:

An air-cooled chiller uses ambient air to remove heat from the refrigerant within the chiller. This process involves a fan blowing air across the coil, which contains the refrigerant. As the air passes over the coil, heat is extracted from the refrigerant, causing it to cool down. The cooled refrigerant then circulates through the chiller to cool a fluid (usually water or glycol) that is used to cool a specific application or equipment. Air-cooled chillers come in a wide range of cooling capacities. Smaller units are often used to cool equipment like laser cutters and larger units can be used for data centers, factories, or other industrial spaces.

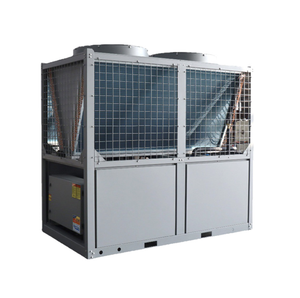

Water-cooled chiller:

A water-cooled chiller cools a liquid by removing heat from the liquid using a refrigeration cycle. The process involves the circulation of water (cooling water) through the chiller to absorb the heat. This water is then cooled by the chiller's evaporator, where the heat is absorbed by the refrigerant during its evaporation process. The cooled water is then recirculated to absorb heat from the application or equipment again. Water-cooled chillers are typically more efficient than air-cooled chillers. They are commonly used in large commercial buildings, industrial facilities, and other applications where high cooling capacity is required.

Typical specifications for a 40 hp industrial water chiller include voltage, refrigerant, cooling capacity, and water flow rate.

Voltage:

The nominal voltage can differ depending on the installation site. The factory default is 460V 60Hz 3-phase.

Refrigerant:

Option for R-410A, R-407C, or R-134A.

Cooling Capacity:

This is the ability of the chiller to absorb heat from a secondary loop. For the 40 hp water chiller, it is 480,000 to 486,000 BTU/hr. or 140-150 Ton. The actual cooling capacity can vary depending on the chiller's design, operating conditions, and other factors.

Water Flow Rate:

Flow rates can vary depending on how the chiller is designed and its application. For a 40 hp chiller, it can be between 800 to 840 GPM based on a 10-degree temperature difference.

A regular maintenance program helps ensure optimum chiller plant performance while reducing energy use and operating costs. The following are some recommended maintenance practices for a Chillers:

The 40hp chillers are commonly used in industries that require large quantities of chilled water or other fluids. Here are some common usage scenarios:

Demand analysis

When choosing a 40hp chiller, people should determine the cooling capacity required. Conducting a demand analysis is vital as it helps to consider the factors influencing the capacity. These factors might include the size of the space, heat load, operating temperature, and expansion plans.

Energy efficiency

During the selection process, it is important to prioritize 40hp chillers with impressive energy efficiency. Such chillers possess high performance that reduces operating costs and environmental impact.

Noise level

To minimize distractions and disruptions, it is a good idea for buyers to consider the 40hp chillers' noise levels. The type of chiller, model, and operating condition determines the noise level of a chiller. People can install the chillers in quiet zones or use them during off-peak hours to mitigate this concern.

Type of refrigerant

Refrigerants play a major role in the 40hp chillers’ performance, energy efficiency, and environmental impact. Therefore, it is important to choose the one that strikes a good balance between these factors and considers the refrigerant's availability.

Installation and maintenance

Considering the installation and maintenance process of 40hp chillers is essential for long-term success. Choosing a refrigerating machine that has straightforward installation and regular maintenance requirements can save unnecessary costs and downtime in the future. It would be best to work with a supplier with excellent support and service network.

Budget and total cost of ownership

It is easy for buyers to select a 40hp chiller when they have a budget. Although upfront costs are an important consideration, people should look at the total cost of ownership. This includes operating and maintenance expenses over the lifespan of the chiller.

Q1: What is a chiller 40 hp used for?

A1: A 40-horsepower chiller is used to extract heat from liquid in a refrigeration cycle to cool it. It is typically used to chill water in different industries such as food processing, plastics, packaging, pharmaceuticals, data centers, and telecommunications, as well as to make ice.

Q2: How many tons is a 40 hp chiller?

A2: Since chillers are measured in tons, it is important to know that 1 horsepower is equivalent to 0.284 tons. Therefore, a 40 hp chiller is approximately equal to 11.36 tons.

Q3: Does a chiller consume electricity?

A3: Yes, chillers are electrical equipment that consumes power to function. The power consumption varies depending on the size, capacity, efficiency, and operating conditions of the chiller.