(421 products available)

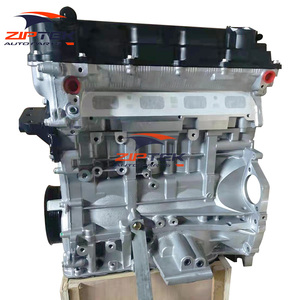

There are two main types of the Mitsubishi 4B12 engine, which include the 4B12 DOHC and the 4B12 SOHC.

The 4B12 DOHC engine

The 4B12 DOHC is known for its high efficiency and performance. The 4B12 Mitsubishi engines have four cylinders and use gasoline as their fuel source. Their valves are arranged in two sets on the engine's cylinder. Each set is responsible for opening and closing the intake and exhaust valves. The 4B12 DOHC engine enables a more precise valve timing control. That allows the engines to draw in more air and exhaust more air. As a result, the 4B12 DOHC engines generate more power and run more efficiently. 4B12 DOHC engines are usually lighter in weight and feature compact designs. This is ideal for small vehicles like hatchbacks. The 4B12 DOHC engines are also used in vehicles that require high performance, such as sports cars.

The 4B12 SOHC engine

The 4B12 SOHC engines have a similar construction to the 4B12 DOHC engines, with minor differences. The 4B12 SOHC engines have a single cylinder head on each engine block. This means that the intake and exhaust valves are controlled using a single camshaft. The 4B12 SOHC engines have a slightly less efficient and less powerful engine output compared to the 4B12 DOHC engines. This is because the SOHC camshaft has to control all six valves in each cylinder. As a result, the intake and exhaust valves may not be opened and closed simultaneously as precisely as required, affecting the engine's overall performance. Nonetheless, the 4B12 SOHC engines are more cost-effective and simpler to manufacture.

Regular oil changes

Fresh oil and an oil filter are required to clean and protect the 4b12 engine from damage regularly at specified intervals. This allows the driver to maintain proper lubrication and prevent wear and tear on essential components.

Air filter replacement

The 4b12 engine requires a clean air supply, which is why the air filter should be replaced regularly. This allows the driver to ensure that unrestricted airflow is maintained and prevents debris from entering the engine, which can cause damage over time.

Coolant flushes

Overheating is a significant risk for the 4b12 engine, so it is crucial to remove old coolant and replace it with fresh regularly. This allows the driver to maintain optimal temperature control and prevent engine damage from high heat levels.

Spark plug inspections

The condition of the spark plugs should be checked periodically on the 4b12 engine. This allows the driver to ensure proper ignition and smooth operation. Replacing worn plugs helps maintain fuel efficiency and prevents potential misfires.

Timing belt replacement

There is a specific mileage or time interval that the driver must replace the timing belt on the 4b12 engine. This allows the driver to prevent potentially expensive engine damage from a snapped or worn belt, which can cause components to become out of sync.

Fuel system cleaning

Over time, deposits can build up in the fuel system of the 4b12 engine, affecting performance. Using specialized cleaners or additivities at recommended intervals helps remove these deposits. This allows the driver to maintain optimal fuel delivery and engine efficiency.

Regular inspections

Regular visual inspections of essential components such as hoses, belts, and fluids are required to detect any potential issues early on in the 4b12 engine. This allows the driver to address any problems promptly before they escalate into more significant, costly repairs.

Choosing the right 4B12 engine is essential for meeting specific performance and reliability requirements. Here are some key factors to consider when selecting a 4B12 engine:

Before engaging in DIY activities, ensure to read the owner's manual to understand the basic steps involved in replacing parts of a 4B12 engine. To replace the engine, follow the steps below:

Firstly, to make sure that the new engine fits into the car, it is important to determine whether the engine will need to be replaced or not. This is because several engines can power a single vehicle. Disconnect the battery before starting the replacement process. This will help prevent accidents and ensure the safety of the mechanic.

Go ahead and drain all the fluids in the 4B12 engine. This includes oil, coolant, fuel, and water. After that, remove the air intake system and exhaust system connected to the engine. This also involves disconnecting the catalytic converter, muffler, and exhaust pipes.

Next, disconnect the engine from the transmission system. This is done by removing the engine's mounting bolts. The transmission system includes the driveshaft, transmission fluid lines, and electrical connections.

Once done, lift the engine using an engine hoist or crane. Unmount the engine from the motor mounts and lift it out of the vehicle. After the old engine has been removed, place the new 4B12 engine onto the motor mounts and connect it to the vehicle's exhaust system, intake system, cooling system, electrical system, and transmission system.

Once done, fill the new 4B12 engine with oil and other necessary fluids. These fluids include coolant and transmission fluid. After that, connect the battery and start the vehicle to ensure that the new engine works perfectly.

Check for any leaks or unusual noises and make necessary adjustments. Once satisfied, reassemble any remaining parts and close the hood.

Q1: Are 4b12 engines good?

A1: Generally, the 4B12 engines are good and reliable. They have average fuel efficiency and high power output. However, the quality of the engine largely depends on how well it is maintained and serviced.

Q2: What is the common problem with the 4b12 engine?

The most common problem with the 4B12 engine is the excessive oil consumption issue. However, this problem mainly occurs in older engines or when the engine has not been properly maintained.

Q3: How can users ensure they get a good condition 4b12 engine?

To ensure they get a good condition 4B12 engine, buyers are recommended to purchase from reputable suppliers. They can also inspect the engine condition and service history before purchasing.