(217 products available)

Woven Filter Mesh

A woven filter mesh utilizes fine interwoven threads, which can be made from various materials such as stainless steel, nylon, polyester, and others. The filters work by trapping excess solid particles within the liquid, leaving the processed liquid free of sediment. Woven filter meshes are often used as wastewater filters, which works by straining the solids and debris before it moves on to the next phase of treatment.

Laser Punch Filter Mesh

A laser punch filter mesh works by creating holes in a single layer of metal in a particular pattern. This creates a strong and reusable filter that can be used for a long time. Like the woven mesh filter, laser punch filter meshes are also used in the production of drinking water. They can help remove contaminants, impurities, and unwanted particles to produce clean drinking water free from any wastage.

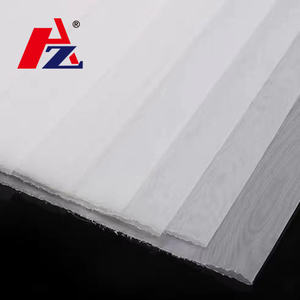

Non-Woven Filter Mesh

Non-woven filter mesh fibers are thermally bonded to create a unique fabric. It creates a perfect filter for air and liquid applications. Non-woven filter meshes, like the woven filter, can also be used in the petroleum industry. They aid in straining crude oil from natural resources. When oil is extracted from the ground, the filter mesh is used to remove any debris or material that may be present alongside the oil.

Rigid Filter Elements

Rigid filter elements are often assembled in tubular form with a plastic end cap. The filter is then used to contain the mesh so that the solution of contaminants can pass through the side walls. Rigid filter elements can be used for the extraction of natural gas. Natural gas filter meshes work by extracting and processing natural gases from rock formations deep below the earth's surface by utilizing filter meshes.

Filter mesh specifications are determined by various factors, including application requirements, material options, hole shapes, sizes, densities, etc.

Application requirements

What needs to go through the filter? What should the filtered product be? These two questions are very critical when deciding on mesh specifications. For instance, in oil filtration, filters must keep out any particles that might clog or wear out engines. So, oil filter mesh has to be small enough to trap those particles but still let the oil flow freely. The same goes for water filters. They have to catch dirt, bacteria, and algae but allow clean water to pass through.

Material options

The filtered product should also govern the filter mesh material. For example, steel filter mesh is strong and long-lasting. It works great in high temperatures and pressures, making it a suitable choice for oil filtration. Such demanding conditions can quickly wear out other materials. Nylon is more suitable for the water filtration industry, particularly seawater reverse osmosis filters. It's resistant to corrosion from salt water and durable under constant use.

Hole shapes, sizes, and densities

What gets filtered through the mesh will also influence its hole shape, size, and density. Coffee filters aren't suited for swimming pool filters because their holes are too big. Swimming pool water has a lot of small particles like dirt, leaves, and algae. If the holes in the filter are large, things like dirt will go through into the water system. So, pool filters need mesh with much smaller holes. Otherwise, all the dirt stays in the water!

In brief, filter meshes must be made from corrosion-resistant materials. They must also have large and small holes to catch various particles. Above all, they're designed to let water flow freely while holding back dirt.

Washing and Cleaning:

It is essential that filter meshes get a regular wash to remove all deposits, including bacteria and algae. Manufacturers recommend warm water and a non-abrasive detergent. After that, they suggest thoroughly rinsing the filter and allowing it to dry. This is important because any retained impurities will disintegrate into the water in just a few days.

Considering its construction, the 500um filter mesh has many applications, especially in filtration. The following list elaborates on some of its uses:

When selecting 500um filter mesh, it's important to consider the material, mesh size, weave style, diameter, durability, chemical resistance, and application requirements.

Material

Users should consider the mesh material, as different materials have varying levels of strength. For example, Stainless steel filter mesh with 500um holes has a strong enough aperture to give desirable filtration results. Also, needs a lot of force before it can break or get damaged.

Mesh Size

Users should ensure that the mesh size is compatible with their filtration needs. If they decide to use a 500um mesh to filter a certain liquid or gas, they should ensure that it will capture all the desired particles and leave the required ones behind.

Weave Style

Users can choose between a twill weave and a plain weave, depending on their needs. Opting for the right choice can improve the filtration efficiency and the material's performance.

Aperture Diameter

The aperture diameter in filter mesh refers to the size of the holes in the material. While 500 microns is equivalent to 0.5 mm, not every hole in the mesh will be exactly that size. Some might be larger or smaller, so users should expect a variation in size. This also means that the filtration results might vary. If a mesh has larger than usual holes, some particles could go through that the filter intended to stop.

Durability

Users should choose a mesh filter that is strong and can last long to perform its filtering job for a very long time. Also, the mesh should be durable enough to withstand whatever force or pressure is used to get the liquid or gas through it.

Chemical Resistance

Users should ensure that the mesh material can withstand the chemical components of whatever liquid or gas it's filtering. If not, the mesh may degrade over time and stop working or break down, letting unwanted chemicals pass through.

Application Requirements

Users should also factor their specific application needs into their decision-making. Whether it's temperature, flow rate, or pressure compatibility, users should ensure that the mesh performance in these areas is superb and meets the requirements of their application.

Q: How to keep the filter mesh working long?

A: After using, put the mesh in soapy water. Use a soft brush to clean it. Rinse it with clear water. You can also boil it in water, which can kill any bacteria. Once the mesh is clean, there will not be any clogging. Store the filter in a dry place.

Q: Does a 500um filter mesh catch pollen?

A: Yes, a 500 um filter mesh can catch pollen because it is larger than pollen particles. The pollen size ranges between 10um and 100um. Using a filter mesh with a 500um hole will prevent pollen from getting into the water.

Q: What does the mesh size mean in filtration?

A: Mesh size means the number of strands in one square inch. It includes the weave of the material. In filtration, it refers to holes in the material. For example, a 500um filter mesh means each hole in the material is 500 micrometers.

Q: Does a 500um filter mesh catch bacteria in water?

A: No, the mesh cannot catch bacteria because they are very small. The bacteria size range is between 1um and 10um, while the 500um filter mesh holes are much larger. A mesh filter with a hole of 1um or smaller will catch bacteria.