(2704 products available)

6mm MDF sheets are versatile and widely used in construction and furniture. They are made from medium-density fiberboard and can be used for different purposes. These sheets are not only cost-effective but are also available in different sizes and forms. Here are the types of 6mm MDF sheets:

Standard MDF

Standard MDF is also known as plain MDF. This is the most common type of 6mm MDF sheet. It is used in a wide range of applications. These applications include furniture construction, cabinetry, and interior wall paneling. This sheet provides a smooth, flat surface that is ideal for painting and veneer. It is also more affordable than other types of MDF.

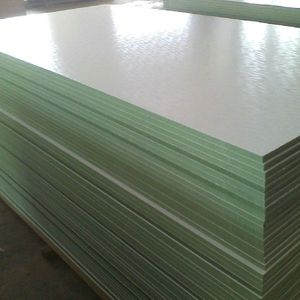

Moisture-Resistant MDF

This type of MDF is also known as Water-Resistant or MR MDF. The 6mm moisture-resistant MDF is specifically designed for areas with high humidity or moisture. Such areas include kitchens and bathrooms. It has a green-colored face and is treated with chemicals during the manufacturing process. The treatment process helps to reduce the risk of mold growth and swelling when exposed to moisture.

High-Density MDF

This type of MDF is also known as HD MDF. The High-density 6mm MDF sheets have a higher density than standard MDF. It provides a heavier and more robust feel. This type of MDF is usually used when a premium finish is required. It is ideal for applications such as high-end cabinetry and custom furniture. Additionally, it is usually produced with less visible fibers and achieves a smoother finish.

Flexible MDF

This type of MDF is also known as bendy MDF. The Flexible 6mm MDF sheet is designed to bend and curve without breaking. It is used for creating convex or concave surfaces. For example, in architectural features and custom designs. It comes in a thin layer of flexible MDF that can be easily shaped and formed according to the user's needs.

veneered MDF

Veneered MDF is a type of 6mm MDF sheet that has natural wood veneer glued onto its surface. It combines the smooth, stable properties of MDF with the appearance of real wood. This MDF sheet is available with different veneer options. For example, oak, walnut, or cherry, to match specific design preferences. It is ideal for decorative applications where a wooden look is desired.

6mm MDF is widely used because it is cost-effective and offers a smooth surface. The applications of this sheet include:

Additionally, the 6mm MDF sheets have several features that make them popular among manufacturers. These features include:

6mm MDF sheets are versatile and commonly used in various industries and applications. Here are some of their usage scenarios:

Furniture Manufacturing:

These sheets are extensively used in the production of furniture, such as wardrobes, cabinets, and drawers. They provide a smooth surface for painting or veneering. Additionally, they are used in making desk, table, and chair components, especially in modern and minimalist designs.

Interior Design and Decoration:

MDF sheets are used to create wall panels, moldings, and trim. They offer a cost-effective and customizable solution for interior design projects. These sheets are also used for decorative purposes such as creating artworks, mirrors frames, and other decorative elements.

Doors and Door Frames:

These sheets are used to manufacture interior doors, including panel doors and flush doors. They provide a smooth surface for painting or veneering. Additionally, they are used in making door frames and casings, providing a consistent and smooth surface for finishing.

Cabinetry and Kitchen Units:

MDF sheets are used to make cabinets, drawers fronts and boxes in kitchens and bathrooms. They offer a smooth surface for paint or laminate coating. Moreover, they are used to construct vanities, countertops, and other storage units in bathrooms and kitchens.

Building and Construction:

These sheets are used as a substrate for laminate flooring, providing a stable and level base. Additionally, they are used as sheathing in non-structural applications, such as interior partitions and underlayment.

DIY and Hobby Projects:

MDF sheets are popular among DIY enthusiasts for making small projects such as picture frames, shelving units, and storage boxes. They are also used by hobbyists for crafting model structures, laser-cutting projects, and other craft activities.

Soundproofing and Acoustic Treatment:

MDF sheets can be used to create soundproofing panels and acoustic treatment solutions. They help to reduce noise transmission and improve sound quality in rooms and studios.

Electronics and Appliance Casings:

These sheets are used to manufacture casings and enclosures for electronic devices, appliances, and audio equipment. They provide a stable and smooth surface for painting or finishing.

When choosing the right MDF sheet, consider the intended use, required durability, and environmental factors. Here are some tips to help choose the right one:

Consider the Purpose

Consider what the 6mm MDF sheet will be used for. Is it for crafting, building furniture, or something else? Different uses may need different types of MDF. Go for an option that is specifically designed for the intended use.

Look at the Thickness

6mm MDF is relatively thin. But for some uses, a different thickness may be more suitable. If a more robust and stable surface is needed, a thicker MDF of up to 32mm may be more suitable. Consider the load-bearing capacity required when choosing the thickness.

Check the Density

MDF density influences durability and surface quality. Higher density MDF sheets are more durable and stable. They provide a smoother surface for painting or veneering. Lower density sheets are lighter and easier to work with. Consider the weight and strength requirements when choosing the density.

Evaluate the Moisture Resistance

If the MDF will be used in a damp area, choose a moisture-resistant type like water-resistant MDF. These sheets have a green color that makes them easily recognizable. The sheets are treated with a special additive during manufacturing to enhance their resistance to moisture.

Assess the Environmental Impact

Standard MDF releases formaldehyde, a harmful chemical that poses serious health risks. Therefore, consider choosing an MDF with low or no formaldehyde emissions. These sheets are safer for the environment and more suitable for uses where low emissions are important.

Review the Edge Treatment

Edges of the MDF can absorb moisture more easily than flat surfaces. Therefore, consider sealing the edges with a water-resistant product if the sheets are used in a moist area. Also, consider applying primer or paint to the edges to prevent chipping during use.

Think About Ease of Cutting and Shaping

When choosing an MDF sheet, consider how easy it is to cut and shape. If the project requires complex shapes and precise cuts, opt for a sheet with high-quality density. This will ensure that it provides a smooth finish and accurate cut.

Q1: What does MDF stand for?

A1: MDF means medium density fiberboard. It is a type of engineered wood used in building applications.

Q2: What are the disadvantages of MDF?

A2: Some of the disadvantages of MDF include its susceptibility to damage from impact. MDF can also be affected by moisture, especially the standard MDF. MDF also has a large weight making it hard to handle when building or installing.

Q3: What is the difference between MDF and particle board?

A3: The main difference between MDF and particle board lies in their production. MDF is made from fine wood fibers, while particle board is made from larger wood fragments or particles. This difference in manufacturing leads to MDF having a smoother surface than particle board.

Q4: Is MDF a good material?

A4: MDF is a good material for building and construction. It is a cost-effective alternative to solid wood. MDF is also versatile, smooth, and stable. It doesn't warp or shrink like other wood materials, making it a great option for many uses.