(860 products available)

An 8hp chiller comes in various types with different features and applications. The main types are:

Proper maintenance of an 8hp industrial chiller is crucial for ensuring its optimal performance, stability, and longevity. Here are some maintenance tips for 8hp chillers:

The proper maintenance of 8hp industrial chillers can help prevent mechanical failures, extend their service life, and ensure they operate at peak efficiency. It is recommended to establish a regular maintenance plan and have professional maintenance personnel carry out the tasks.

Industrial refrigerant chillers are used in various industries and applications that require consistent refrigeration.

Food Processing and Packaging

Nitrogen chillers are used in the food processing industry to cool food quickly. This is helpful for preserving the quality of the food and extending its shelf life. Industrial cooling machines are also used in the food industry for cooling.

Pharmaceuticals

Chillers are very important in the pharmaceutical industry. They let pharmaceutical companies maintain a constant temperature for making drugs, storing them, and testing them.

Plastic Injection Molding

In the plastics industry, chillers are used to help with plastic injection molding. They cool down molds quickly after molds are released. This increases production speed and improves mold accuracy.

Data Centers

Data centers need to have machines that cool them, so refrigerators can be used to cool down the servers and keep them from overheating. Refrigerators help keep the temperature constant.

Laser Systems

Laser systems need to work well all the time, so Laser chiller machines cool down the laser so it can work better. Refrigerators help keep the laser stable and run at its best.

Medical Imaging Equipment

Ct scanners, MRI machines, and other medical imaging tools use chillers to cool down the components that make them work well.

HVAC

Chillers are used in the air conditioning (HVAC) systems of both large buildings and small ones. They are responsible for removing heat from the building and thus keeping it cool and comfortable.

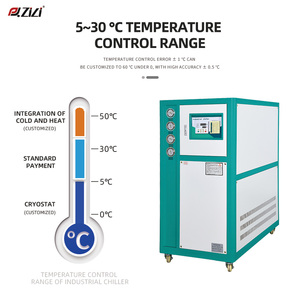

Application requirements analysis:

Firstly, users need to determine the specific application areas and needs, including the type of products to be cooled, the temperature and pressure requirements, the cooling capacity needed, etc. These will affect the selection of the suitable type and specifications of the refrigerated machine.

Refrigeration technology:

Users need to understand different refrigerating technologies, such as vapor compression refrigeration, absorption refrigeration, etc., and choose the appropriate technology based on their needs and application scenarios.

System efficiency:

Users need to evaluate the energy efficiency and performance of the refrigerating system, such as its coefficient of performance (COP), cooling capacity, power consumption, etc., and choose a high-efficiency, energy-saving system to reduce operating costs.

Equipment reliability:

Users should choose chillers manufactured by reputable brands and reliable equipment to ensure their stability and reliability. At the same time, they need to consider the maintainability of the equipment, such as the availability of spare parts and maintenance services, etc., to facilitate its long-term operation.

Environmental considerations:

Users need to consider the environmental impact of refrigerating machines, including greenhouse gas emissions, etc., and choose environment-friendly refrigerants and energy-efficient equipment to meet environmental standards and sustainable development goals.

Cost considerations:

Users need to consider the purchase and operating costs of refrigerating machines, including electricity expenses, maintenance costs, etc., and choose suitable equipment according to budget constraints and cost-performance ratios.

Q1: How has the 8hp chiller technology changed over the years?

A1: The 8hp chiller technology has progressed in areas such as variable-speed drives, connectivity for Internet of Things (IoT) integration, and environmentally friendly refrigerants.

Q2: Can people customize 8hp chillers?

A2: Several manufacturers can provide a variety of customization options for 8hp chillers, including specific sizes, configurations, and component selection to meet certain performance requirements.

Q3: How long can a well-maintained 8hp chiller last?

A3: If it is regularly maintained and repaired in time when it encounters problems, an 8hp chiller can have a service life of more than ten years, or even up to twenty years or longer.

Q4: How noisy are 8hp chillers?

A4: The noise level of an 8hp chiller may vary according to factors such as its horsepower, whether it adopts a scroll compressor or other types of compressors, and its operating conditions. Generally, the chillers are designed to reduce the noise as much as possible.