(1188 products available)

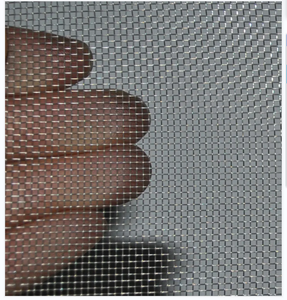

The stainless steel mesh is a woven filter that provides high flow rates and excellent filtration. 904L ss filter meshes are used to separate solid particles from gas or liquid. They can be used as a preseparator to avoid clogging the next filter element. They can be used to separate bacteria in the food and beverage industry or to filter air in a cleanroom environment. Here are some types of 904L filter meshes.

The wire used for 904L mesh filters has a diameter of around 0.20 mm but may vary according to the specific application. The opening size is the size between the wires. It is often called the 'aperture'. An aperture size of 0.45 mm is very common. Other sizes vary between 0.1 mm and 1.0 mm. The usual roll width is around 0.91 mm, but filter mesh can also be made in widths between 0.45 mm and 1.2 mm. The length of 904L mesh filter rolls can be as much as 150 m. Standard specification for mesh filters is as follows:

Moreover, various other specifications are also possible. 904L stainless steel filters are usually manufactured using a continuous weaving process, which results in wire mesh with finer openings and is exclusively made for filtering.

Maintenance:

The mesh filter can be cleaned easily by rubbing it with bar soap that is neutral when doing ordinary cleaning. But when the mesh filter is regularly exposed to petroleum products, hard water, or chemicals, the filters must be cleaned thoroughly and occasionally, which should also be done in normal use.

904L filter mesh can be used in various industries and applications.

Oil and gas industry

904L SS filter mesh can serve as a downhole gas lift filter. Gas lift filters are used to separate gas from liquids at the bottom of the well. They increase the viscosity of the liquids to enhance oil production. Using 904L gas lift filters can improve resistance against sour gas applications and prolong the lifespan of the filters. Additionally, 904L SS filter mesh can manufacture strainers, screens, and sieves, and its anti-corrosive properties are suitable for use in offshore platforms.

Pulp, paper, and textile industries

904L filter mesh can act as a mold and press wire filter in the pulp and paper-making process. These meshes will not corrode in dewatering sections or in the presence of papermaking additives. In the textile industry, 904L filter mesh can be weaved into screens, sieves, or strainers to separate impurities, fibers, and contaminants and allow liquid or air passage.

Aerospace and automotive industries

904L filter mesh can act as strainers and screens in fuel, lubricant, cooling, and hydraulic systems in aerospace and automotive applications. As these systems encounter various fluids and environmental conditions, the filter meshes should be durable and provide consistent performance. Moreover, because of its effective filtration and separation properties, 904L filter mesh can be used to manufacture air, oil, and fuel filter elements in vehicles.

Food processing and bioscience fields

904L SS filter mesh can be used as a filter, strainer, or sieve in food processing and biopharmaceutical applications to separate solids and purify, clarify, or concentrate liquids. 904L mesh filters will not corrode when exposed to harsh cleaning procedures to comply with strict hygiene and safety requirements.

Water filtration and environmental protection

The water management and environmental protection industry relies on filter meshes. 904L filter mesh can manufacture filter elements, washers, strainers, and more. It can be used to prevent contaminants in water conveyance systems, CO2 capture processes, and wastewater treatment systems.

Medical and healthcare industry

In the healthcare and medical fields, 904L filter meshes can be used as screens and strainers in diagnostic devices and medical equipment. For example, those meshes could be components in blood pumps, dialysis machines, or bioreactors to separate cells, tissue, and contaminants.

Buyers should consider the following factors when choosing a 904L SS filter mesh for themselves:

Mechanical durability

Application environments can have different pressures, temperatures, and other factors. Buyers need to ensure that the filter mesh has enough mechanical strength to cope with the applied circumstances, which will prevent the mesh from being deformed or damaged.

Corrosion-resistance

Filtration demands are distinct, which could require different aperture sizes and densities. Buyers need to ensure that the filter mesh selected can meet their own filtration demands.

Fabrication abilities

Buyers may need to assess the fabrication abilities of the supplier. Whether the supplier can provide the required fabrication abilities, such as cutting, welding, etc., to ensure that the filter mesh can be properly integrated into the buyer's equipment or system.

Quality control

Good suppliers typically have stringent quality control systems to ensure that each product is inspected and controlled during the manufacturing process. This helps ensure that buyers receive 904L stainless steel filter meshes of consistently reliable quality.

Cost-effectiveness

When choosing a filter mesh, buyers need to consider its cost-effectiveness in terms of performance, quality, and price. It's important to make a choice that is suitable for one's own needs, application scenarios, and budget.

Q1: How does the strength of 904L mesh filter compare to other types of filter mesh?

A1: 904L mesh filter offers strength due to its structure and material. As stainless steel filter mesh coils, it combines stainless steel's strength with the mesh's tensile strength, making it resist pulling and stretching. Moreover, the mesh filter provides more strength compared to larger weave filter materials, making it suitable for heavy-duty filtering tasks.

Q2: Is a 904L filter mesh coil waterproof?

A2: Yes, 904L filter mesh coils are resistant to water. The stainless steel material repels water, and its mesh structure permits water to move through while trapping solid particles. This combination makes it an excellent choice for filtering liquids, including water.

Q3: Can a 904L filter mesh (coarse or fine) affect the flow rate of a liquid or gas?

A3: Yes, the size of the filter mesh affects its flow rate. Coarse filter mesh (with fewer lines) allows more liquid or gas to pass through, making it flow faster. Fine filter mesh (with more lines) keeps smaller particles out, but it may make the liquid or gas flow slower because it has more lines resistance.

Q4: Can a 904L filter mesh be cleaned and reused?

A4: Yes, 904L filter meshes can be cleaned and reused unless damaged. Their stainless steel material allows for washing without harm. Keeping them clean prolongs their lifespan and makes them useful again.