(57 products available)

ABB Turbocharger is an essential component of modern internal combustion engines. It provides a solution to the challenge of how to get more power out of an engine without making it bigger. Turbochargers take advantage of the exhaust gases that are produced when fuel is burned in the engine. By using the energy in these gases, a turbocharger can force more air into the engine, allowing it to burn more fuel and produce significantly more power. There are two main types of ABB turbochargers, which are:

Single Turbo

Variable Geometry Turbocharger (VGT)

Single Turbo

Single turbochargers are the most common type found in vehicles today. They use a single turbine and compressor wheel to force additional air into the engine. Single turbochargers are popular because of their simplicity and effectiveness. They work well across a wide range of engine speeds, making them ideal for daily driving and moderate performance needs. Single turbochargers are further divided into low-pressure, high-pressure, and twin-scroll turbochargers.

Variable Geometry Turbocharger (VGT)

Variable Geometry Turbocharger (VGT) is a more sophisticated type of turbocharger. As the name suggests, VGT allows for the geometry of the turbine's inlet guide vanes to be changed. This adjustability enables the VGT to optimize boost pressure across the entire engine speed range. As a result, VGT eliminates turbo lag and provides a nearly instantaneous boost to the engine, making it feel more responsive. This technology is particularly beneficial for smaller engines that require additional power without increasing displacement.

The specifications of ABB Turbochargers vary depending on the model, as they are designed to meet different needs. However, some general specifications include:

Size and Weight

The size and weight of the turbocharger affect its performance. Turbochargers with smaller sizes and weights spin faster, producing higher pressure and volume of air. Lighter and smaller turbochargers also respond quickly to changes in the throttle. However, they are unable to sustain boost at higher engine speeds. Heavier and larger turbochargers can maintain boost at higher engine speeds, but they have slower spinning rates and lag.

Materials

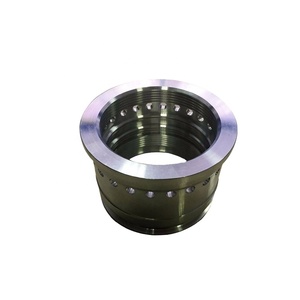

Turbochargers are made using different types of materials. Each material affects the performance of the turbocharger in various ways. Common materials used in turbochargers include inconel, cast iron, stainless steel, and aluminum. Turbochargers made from inconel offer superior performance and are more expensive compared to other materials.

Engine Displacement

Different turbochargers are designed to be used with engines of varying sizes. Some turbochargers are suitable for small engine displacements, while others are designed for use in larger engine displacements. The turbocharger size needs to match the engine size for optimal performance.

Compressor and Turbine Wheel Diameter

The wheels of the turbine and compressor in the turbocharger play a vital role in determining the amount of boost produced and the turbocharger's performance. Larger wheels move more air, producing higher boosts. However, they require more energy to spin compared to smaller wheels. As a result, larger wheels may cause lag. On the other hand, smaller wheels spin quickly and produce boosts instantly, but they require less energy to spin.

Aspect Ratio

Turbochargers have varying aspect ratios, which affect their performance. The aspect ratio is the ratio between the height and width of the turbine and compressor housing. Turbochargers with high aspect ratios produce more boost at higher engine speeds, while those with low aspect ratios offer quick response times.

ABB Turbocharger maintenance requirements are as follows:

Choosing the right ABB turbocharger for a specific application requires careful consideration of several factors to ensure optimal performance, efficiency, and reliability. Here are some key factors to keep in mind when selecting an ABB turbocharger:

Engine Characteristics:

The type and size of the engine, its performance requirements, and operating conditions should be considered. Different engines may benefit from different turbocharger sizes and configurations to match their power delivery and response characteristics.

Vehicle Type and Use:

Vehicle type (e.g., passenger cars, trucks, buses, etc.) and its intended use (e.g., city driving, highway, off-road) can affect the choice of turbocharger. For example, vehicles requiring quick acceleration may benefit from a smaller turbocharger for faster spool-up times.

Altitude and Temperature:

Operating conditions such as high altitude or extreme temperatures can impact engine performance and, consequently, the turbocharger selection. At high altitudes, a turbocharger that compensates for reduced air density may be required to maintain engine performance.

Boost Pressure and Performance:

The desired boost pressure and engine performance characteristics should be considered. A larger turbocharger can provide higher boost levels and better performance at higher engine speeds, while a smaller turbocharger may offer quicker boost response and better low-end torque.

Size and Trim:

The size and trim of the turbocharger's compressor and turbine wheels influence the boost response, efficiency, and power band of the turbocharger. Selecting the right size and trim is critical to matching the turbocharger's performance characteristics to the engine's requirements.

Compressor Map:

The compressor map of the selected turbocharger can be analyzed to ensure that its operating range aligns with the engine's air requirements across the entire speed and load range. Choosing a turbocharger with a compressor map that provides stable boost and efficiency is crucial.

Emissions Compliance:

The chosen turbocharger must meet emissions regulations for the specific application and region. Some turbochargers are designed with features to reduce emissions further, such as improved efficiency and lower exhaust temperature.

Reliability and Durability:

Consider the reliability and durability of the turbocharger in relation to the application requirements and operating conditions. Features such as high-quality materials, cooling options, and robust bearing systems can contribute to the longevity of the turbocharger.

Warranty and Support:

Warranty coverage and after-sales support for the selected turbocharger should also be considered. Choosing a turbocharger from a reputable manufacturer with a solid warranty and support can provide peace of mind and assistance in case of any issues.

By carefully considering these factors and selecting the right ABB turbocharger for the application, users can achieve improved engine performance, increased efficiency, and reduced emissions, resulting in a better overall driving experience and environmental benefits.

Some basic tools that can help when replacing any turbocharger from the ABB Turbocharger catalog are as follows.

Some replacement instructions are as follows:

Q1: How long does a turbocharger last?

A1: A turbocharger can last between 100,000 to 200,000 miles. However, the lifespan of a turbocharger can be affected by several factors, such as driving habits, engine oil quality, and more.

Q2: Can users upgrade their turbochargers to get more power?

A2: Yes, upgrading to a larger turbocharger can generate more power. The larger turbo can force more air into the engine, allowing more fuel to be burned and resulting in increased horsepower. However, the larger turbo may need other modifications to the exhaust and intake system to fit.

Q3: Can anyone replace a turbocharger?

A3: Replacing a turbocharger can be complicated and requires some mechanical knowledge. Following the proper steps and using the right tools is important. If unsure, it's best to have a professional mechanic replace the turbo.

Q4: Does the turbocharger require maintenance?

A4: Yes, maintaining the turbocharger is important to ensure it lasts and performs well. Maintenance includes regular oil changes, letting the car idle before turning off the engine, and keeping the air intake clean.