(5233 products available)

There are different air hose 10mm types on the market today. They include:

Rubber Air Hose

Commonly used throughout industries, the durable rubber air hose is well-known. Its elasticity allows it to bend without breaking. It is also resistant to abrasion, oil, and weather elements. Hence, it is suitable for both outdoor and industrial settings. Its flexibility makes it ideal for use in construction areas where it can be exposed to different elements. Additionally, it retains its elasticity even after long-term use.

PVC Air Hose

Plasticized polyvinyl chloride (PVC) is a material often seen in the lighter air hose. It is lighter and less expensive than rubber, though not as strong. This makes it a popular choice for home use, gardening, and light industrial applications. The hose is rigid and does not fold easily. Therefore, it is not suitable for heavy-duty applications. Further, it is available in a variety of colors. This allows users to select a visually appealing option.

Polyurethane (PU) Air Hose

Polyurethane (PU) is a key material used to manufacture air hoses. Highly resistant to abrasion, it is also flexible in cold and hot temperatures. The PU air hose is lightweight, which makes it ideal when portability is necessary. Common usage of this hose includes pneumatic tools, as its durability can withstand repeated bending and kinking. The transparent or semi-transparent nature of this hose allows users to see if any blockages exist.

Reinforced Air Hose

In high-pressure conditions, a reinforced air hose is commonly used. Steel wire or polyester mesh are some of the available reinforcements on this hose. This makes it ideal for industrial applications where high pressure and heavy loads are likely. Manufacturing facilities, construction sites, and workshops usually incorporate the hose. Additionally, it can withstand kinks and abrasions, contributing to its long-lasting nature.

Hybrid Air Hose

Combining both PVC and rubber properties, a hybrid air hose is as well preferred. This hose is flexible, lightweight, and has the durability to withstand different environments. Used widely in both residential and commercial settings, this hose can handle a range of temperatures and pressures. Its versatility makes it suitable for various applications, including tire inflation, air tools, and leaf blowers.

Several factors come into play when selecting an air hose 10mm. They include the material, length, flexibility, and application.

Materials

A flexible air hose is primarily made from rubber, PVC, polyurethane, or a combination of these materials. Each material offers unique advantages, like rubber's durability and PVC's lightweight properties. Thus, consider the operation environment's demands before settling for one. They include the surroundings and the tasks the hose will perform.

Length and Diameter

Various air hoses' lengths and diameters affect their performance considerably. A longer hose reduces the air pressure reaching the tool. This is due to the increased resistance over distance. Thus, do not allow a long hose to decrease efficiency. A 10mm diameter hose has a good flow rate for most applications, ensuring adequate air delivery. It is commonly used with tools that require high air volume.

Pressure Rating

Should meet the compressor's maximum pressure, the hose should possess a suitable pressure rating. It prevents the hose from bursting or collapsing while under stress. This can lead to a dangerous situation. Ensure that the chosen hose can handle more than the typical operating pressure of the system.

Flexibility and Coiling

The hose should be flexible enough for easy handling without breaking. Also, it needs to be coiled for compact storage. This flexibility comes in handy during maneuvering the hose around obstacles or moving it from one place to another. PVC and polyurethane hoses possess good flexibility, even in low temperatures.

Compatibility

The hose fittings should be compatible with the tools and the equipment used in the general system. This is to avoid any connection issues. Some fittings are easily interchangeable. This allows for the flexibility of using the hose with different tools. When possible, utilize quick connect/disconnect fittings for seamless integration.

Cost vs. Durability

The budget and usage expectations should be considered when getting a hose. Cheaper hoses are less durable and may wear out quickly, especially in heavy use environments. A more durable hose will be worth the investment in the long run. Hybrid air hoses are known for their sturdy construction yet affordable prices for air hose users.

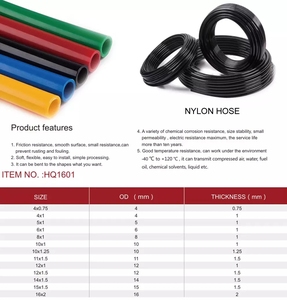

Some of the air hose specifications include working pressure, temperature range, and hose length. Others are outside diameter, inside diameter, and fittings. Knowing them ensures optimal performance, durability, and safe use.

Working Pressure

The working pressure is the maximum pressure an air hose can handle during operation. Normally, it should be just right for the tools and air compressor. Operating above this pressure may lead to hose failure. It is critical to select a hose with an appropriate working pressure rating for an application.

Temperature Range

Every hose comes formulated with a specific temperature range. Operating an air hose beyond its temperature range can cause damaging effects. Users should select a hose that can withstand environmental conditions. Such conditions may be extreme heat or cold since both can adversely affect the hose material.

Length and Diameter

Longer air hoses tend to lower the pressure of the air reaching the tool. This is due to increased resistance over distance. A 10mm diameter hose is ideal for high flow applications. Its wider space allows more air to pass through compared to narrower hoses.

Outside Diameter and Inside Diameter

Outside diameter (OD) and inside diameter (ID) are critical to hose selection. While the ID affects airflow, the OD ensures compatibility with hose fittings. Larger ID means better airflow and vice versa. However, a larger OD makes the hose bulkier and harder to handle.

Hose Materials

Manufacturers make each hose from distinct materials, setting each type apart with unique characteristics. Rubber hoses are tough and flexibly durable. PVC hoses are lightweight but less durable. PU hoses are ideal for cold weather due to their flexibility. Hybrid hoses breakdown easily upon constant flexing. Heavy-duty rubber air hose is suitable for industrial applications.

Fittings

Hose fittings ensure easy connection between the hose and the tools or air compressor. Using the wrong size or type of fitting can lead to air leaks. Leaks are often responsible for reduced tool performance or increased air consumption. Therefore, always ensure that the fittings are compatible with the hose and other equipment.

Kinking and Abrasion

Some specifications, like abrasion resistance and kinking, are worth considering for durability. These specs come in handy for hoses used in rugged work environments. Manufacturers incorporate metal reinforcements in some hoses to enhance their durability in heavy-duty applications.

Rubber hose is the most durable and versatile. This makes it ideal for outdoor and industrial uses. Users can utilize this hose for a wide range of temperatures and conditions. It is also resistant to abrasion and kinking. Hence, it can withstand rough handling and harsh elements. Its flexibility enables easy maneuvering on job sites, allowing it to bend without cracking.

PVC air hose has several advantages. It is lightweight, easy to store, and more affordable compared to other materials. Users also find it versatile for low to medium-pressure applications. Its rigidity enables users to avoid kinking effortlessly. On the other hand, it has a disadvantage. It is less flexible in extreme temperatures, making it difficult to use in outdoor applications when the weather is too cold or hot.

The diameter of an air hose affects airflow rate and pressure. A wider diameter hose allows more air to pass through. This makes it ideal for high-volume applications. Conversely, a narrower hose restricts airflow. This results in decreased air pressure reaching pneumatic tools. Therefore, choosing the right hose diameter is critical in ensuring the tools operate at their optimal efficiency.

One common maintenance practice is to frequently inspect the hose for signs of wear, such as cracks or leaks. Another practice is that the hose should be properly stored when not in use. The storage has to be in a cool, dry place away from direct sunlight. Users should also ensure that the hose is free from moisture and contaminants. These elements contribute to the hose's early deterioration.

Reinforcement helps the air hose to withstand higher pressures. This greater pressure helps to prevent the hose from bursting in industrial or heavy-duty applications. Reinforced hoses have added durability. This allows them to handle extreme conditions while reducing the risk of kinking or abrasions.