(348 products available)

An air max flexible hose is a pipe that carries air to and from different parts of a machine. It is also called a pneumatic hose or air intake hose. This flexible ducting comes in various types depending on the application for which it is used. These are;

Spiral Hoses

Spiral air hoses are coiled or spiral-shaped, which makes them compact and flexible. They stretch when needed but return to their original size when not in use. These hoses are perfect for clean and organized workplaces since they do not tangle. They are mainly used in pneumatic tools like nail guns and spray paint devices.

Recoil Hoses

Similar to spiral hoses, recoil hoses also have a coiled structure. They are made from polyurethane, making them lightweight and durable. Recoil hoses are famous for their ease of use and ability to retract when not in use. They are commonly used in workshops and garages, where they connect air compressors to pneumatic tools.

Silicone Hoses

These air flexible hoses are made of silicone rubber, which is highly resistant to temperature changes. They do not get damaged from exposure to heat, oil, or UV rays. Silicone hoses are used in applications where air is moved from the engine to the intake manifold. They are popular in performance vehicles and racing cars.

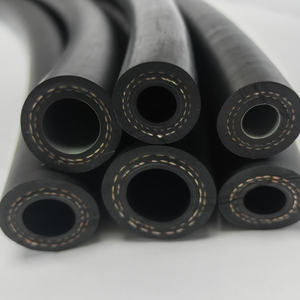

Metal Hoses

Metal flexible hoses are made from stainless steel or aluminum. They are durable, withstanding high pressures and temperatures. Metal hoses are perfect for high-performance applications and environments with sharp objects and extreme temperatures.

Reducing Hoses

These are special types of flexible air ducting that have different diameters on each end. They adapt to various fitting sizes in air systems. Reducing hoses improve airflow and reduce friction in pneumatic systems. They are versatile and used in automotive applications, workshops, and industrial settings.

Coupler and Nipple Hoses

These flexible air hoses come with a coupler and a nipple already installed on the end. This makes it easy to connect the hose to air tools and machines without additional fittings. They are popular in professional settings where quick connections are needed.

Hot and Cold Air Flexible Hoses

These hoses are used in HVAC systems to transport hot or cold air. They are insulated to improve energy efficiency and prevent condensation. Hot and cold air flexible hoses come in various materials, such as fiberglass, plastic, or metal, and are used in heating and cooling systems.

Flexible hoses are used for a variety of applications across different industries. Their primary functions include:

The air max flexible hose has a variety of features that make it ideal for connecting and transferring fluids. These features include:

Flexible hoses have a wide range of applications across different industries and sectors. Some of the primary usage scenarios include:

Aviation:

Flexible hoses are extensively used in aircraft systems. This includes fuel lines, hydraulic systems, and pneumatic systems. Their flexibility allows for easy routing in confined spaces within the aircraft.

Automotive:

Automotive flexible ducting is used in various applications in vehicles. This includes fuel lines, oil lines, coolant hoses, brake lines, and air conditioning systems. Their flexibility helps to accommodate engine movement and vibrations.

Marine:

Flexible hoses are used in boats and ships for fuel transfer, water intake, waste discharge, and hydraulic systems. Their flexibility allows for easy installation in tight spaces and moving parts of the vessel.

Industrial:

Many industries use flexible hoses for fluid transfer in conveyor systems, pumps, and machinery. Their ability to handle misalignments and vibrations makes them ideal for industrial applications.

HVAC Systems:

Flexible hoses are common in heating, ventilation, and air conditioning (HVAC) systems. They connect components such as compressors, condensers, and evaporators. This allows for the smooth flow of refrigerants and air while accommodating small spaces and slight movements.

Oil and Gas:

Flexible hoses are used in various applications in the oil and gas industry. This includes offshore drilling, pipeline connections, and tanker loading/unloading. Their flexibility helps to accommodate ocean currents and vessel movement in offshore operations.

Chemical Processing:

These hoses transport chemicals, acids, and other hazardous materials in processing plants. Their flexibility allows for easy routing and placement in pipelines and machinery.

Food and Beverage:

Flexible hoses are used in the food and beverage industry to transport liquids, gases, and materials. These hoses are hygienic, easy to clean, and resistant to abrasion and wear. For instance, they can be used to transport milk, beer, and other liquids in processing plants and pipelines.

Construction:

Construction sites and projects use flexible hoses for various applications. This includes water delivery, concrete pumping, and hydraulic systems in construction equipment. Their flexibility allows for easy placement and connection in different angles and positions.

When choosing the right flexible hose, consider a few things. First, check the air hose's inner diameter to ensure it matches the compressor outlet and the tool's inlet. Second, look at the maximum working pressure. The air hose's working pressure should be equal to or higher than the compressor's maximum pressure. Third, check the length of the air hose. A longer hose will give you more freedom to move, but it may also reduce pressure and airflow. A shorter hose will give you more pressure and airflow but limit movement.

Also, check the material and temperature rating of the air hose. This will ensure the hose can handle the temperature of the compressor and the working environment. When buying flexible air hoses in bulk, it is essential to consider the type of tools the buyer usually uses. This will help determine the right inner diameter and working pressure for the air hose.

Lastly, the color of the air hose is also important when using it on construction sites. The color makes it easy for workers to see the air hose and avoid tripping over it.

All these factors are important when choosing the right air hose. But the most important thing is to read the manufacturer's recommendations to choose the right air hose for the job.

Q1: What is the maximum length for an air max flexible hose?

A1: There is no standard length for an air max flexible hose. Maximum lengths depend on the hose type and application. For example, flexible ducting can be manufactured in lengths of up to 30 meters. In contrast, hydraulic hoses are usually not longer than 50 feet because longer hoses tend to lose pressure or airflow.

Q2: What are the disadvantages of an air max flexible hose?

A2: Air flexible hoses have low durability compared to rigid hoses. They are also more susceptible to abrasion and damage from external elements. Additionally, they have a lower maximum temperature and pressure rating than rigid hoses. As a result, they are not ideal for high-pressure or extreme temperature applications.

Q3: Can air max flexible hoses be repaired?

A3: It is possible to repair air flexible hoses depending on the extent of the damage and the hose type. Minor punctures or cuts can be fixed using hose repair kits. Leaks can also be fixed using hose clamp repair kits. However, rigid tubing and hoses often cannot be repaired and will require replacements.

Q4: Are air max flexible hoses and ducts the same?

A4: Air flexible hoses and ducts are not the same. Hoses are primarily used for the transfer of air. On the other hand, ducts are used for the distribution of air. Hoses are also used in various applications, while ducts are mostly used in HVAC systems.

Q5: What is the optimal bend radius for air max flexible hoses?

A5: There is no standard bend radius for air flexible hoses. The optimal bend radius depends on the hose type. For example, hydraulic hoses have a minimum bend radius of 3 times the hose diameter. In contrast, pneumatic hoses have a minimum bend radius of 4 to 6 times the diameter. It is important to note that exceeding the bend radius will result in reduced efficiency and increased turbulence.