Introduction to Analog Encoders

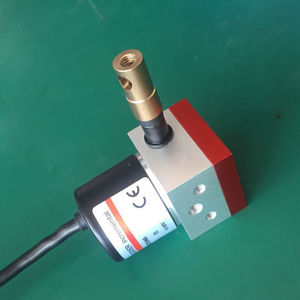

Analog encoders are essential devices in the realm of automation and control systems. They serve as sensors that convert the angular position of a shaft or axle into an analog signal, typically voltage or current. This transformation allows for precise feedback on position, speed, and acceleration which is critical in various industrial applications. With the rising demand for automation and real-time monitoring, analog encoders have become indispensable tools in enhancing operational efficiency and accuracy.

Types of Analog Encoders

When considering an analog encoder, it's important to understand the different types available in the market, each designed for specific applications and environments. Here are the primary types of analog encoders:

- Rotary Analog Encoders: These encoders measure the rotational position of a shaft, providing continuous output in a circular format.

- Linear Analog Encoders: Designed to measure linear motion, these encoders provide accurate readings on linear displacement, making them perfect for applications requiring straight-line movement.

- Incremental Analog Encoders: Incremental encoders generate outputs based on the incremental movement of the shaft and can detect changes in position accurately.

- Absolute Analog Encoders: These encoders provide a unique positional value for each shaft position, ensuring that the exact location is always known, even after power loss.

Applications of Analog Encoders

The versatility of analog encoders allows them to be employed in numerous applications across various industries. Understanding where and how they are used can help you appreciate their significance:

- Industrial Automation: Used in robotics and automated machinery to track movement, position, and speed with exceptional accuracy.

- Medical Equipment: Essential in devices such as MRI machines and robotic surgical tools where precise positioning is paramount.

- Textile Machinery: Implemented in weaving and sewing machines to regulate speed and positioning of moving parts.

- Conveyor Systems: Employed to monitor and control the exact position of items on the conveyor, optimizing material flow in manufacturing.

Advantages of Using Analog Encoders

The integration of analog encoders within operational processes yields numerous advantages that can significantly enhance performance and reliability:

- High Precision: With the ability to deliver fine granularity in position measurement, analog encoders provide accurate data crucial for feedback in control systems.

- Real-Time Data: They offer continuous output, enabling real-time monitoring and control, thus improving response times in automated systems.

- Versatile Integration: Analog encoders can be easily integrated into various systems, ranging from simple devices to sophisticated industrial setups.

- Durability: Built to withstand harsh environments, many analog encoders are resistant to dust, moisture, and other challenging elements, ensuring long-lasting performance.

Conclusion

Analog encoders play a pivotal role in modern automation and control systems, providing crucial feedback that enhances performance and operational efficiency. Understanding their types, applications, and advantages enables businesses to select the right encoder for their specific needs, ensuring precise motion control and monitoring. As industries continue to evolve towards automation, the significance of analog encoders will undoubtedly increase, marking them as a cornerstone in advanced engineering solutions.