Types of small box locks

Small box locks are used in many locking systems to improve security against theft or unauthorized access; therefore, it is crucial to understand their varieties.

Cylinder locks

Cylinder locks use a key-operated rotating cylinder to offer improved security and are common in applications like cabinets, boxes, and furniture. Since these locks provide moderate security, they are widely used in applications where security interests are not significantly required but convenience and ease of access are important.

Padlocks

Padlocks are portable and often used for securing boxes, gates, and lockers. Their size varies, with small padlocks frequently used for lightweight applications. When considering a small padlock box lock, the shackle material and dimensions are crucial, especially stainless steel, for corrosion resistance.

Cam locks

Cam locks, commonly found in cabinets, drawers, and vending machines, consist of a rotating cam that locks into place when the lock's cylinder is turned with a key. Often made of zinc, they can be chrome-plated for durability and a polished look. This lock's easy installation, usually through a single hole, makes it popular for securing access to minimal-risk areas. They come in keyed, combination, and key-retaining designs.

Deadbolt locks

Deadbolts provide added security for box containers, requiring a key or thumb turn to lock or unlock. Single-cylinder deadbolts use a key on one side and a thumb latch on the other, while double cylinder requires keys on both sides, offering higher security where glass is present. Although usually larger, small deadbolts ensure strong locking mechanisms.

Lever locks

Lever locks utilize a lever mechanism and are often found in wooden furniture and toolbox applications. Generally, these locks come in different lever shapes to provide varying security levels and ease of access.

How to choose small box locks

One of the key aspects of having box locks is learning how to choose those small box locks that are more effective depending on the use.

- Security needs: Security needs are primarily determined by what the locked box contains and the general security risks in that environment. High-value or sensitive items require stronger locks, like deadbolts or lever locks, while low-value items might only need simple cam or cylinder locks. To avoid lock picking or duplication, also consider using a keyway restrict that is different from the common ones.

- Material and durability: Small box lock materials must be selected according to the environment they will be placed in, ensuring they withstand weather, moisture, or corrosion. Stainless steel or brass locks are preferred in such outdoor or humid environments. For indoor use, zinc or nickel-plated locks are often just as effective and more cost-effective.

- Size and fit: The size of the lock should correspond to the box in which it will be locked, as it should not be too large or too small for effective locking. Measuring the space where the lock will be fitted ensures it does not overwhelm or underutilize the area and provides a smooth functioning locking mechanism.

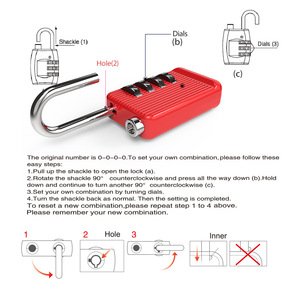

- Ease of use: Ease of use is important, especially for frequently accessed locations. Combination locks offer the ease of access without keys but may need recalibration, whereas key locks are easier for the casual user. Some locks may be more accessible for users with fewer skills, particularly in multi-user environments.

- Cost: The costs must be considered in relation to security and durability. Often, a more expensive lock pays off in better security and has a longer lifespan per unit. Buying in bulk also goes a long way in cutting costs, yet it assures uniformity in security measures throughout that business.

Specifications and maintenance of small box locks

Small box lock specifications and maintenance are pivotal to the overall operational effectiveness and lifespan of the product.

- Lock material: As for maintenance, the lock materials also determine the lifespan of the lock, with stainless steel and brass having longer life spans and virtually maintenance free, while zinc alloy requires more attention. While brass has naturally occurring antibacterial properties, it also requires polishing to avoid tarnishing. Corrosive environments may require materials or coatings, such as nickel plating, that are more durable against corrosion. For maintenance-free locks, lubricate periodically for optimal locks, usually every 6–12 months, depending on the use and environment.

- Type of key or combination: Consider whether the lock wants a key or is a combination, with some combination locks requiring the user to store or change the combination periodically to avoid being forgotten. Also, some locks feature master keys - these allow access to several locks, but care must be taken when numbers or codes are not similar. Key retaining locks must be fixed, particularly in areas where the key can easily be misplaced, as the key stays in the lock until it's locked.

- Sizing: Traditional box lock sizes have gone down to 90 by 50 millimeters, but these measurements can vary greatly depending on user needs. Small-sized locks are ideal for lightweight applications like securing gates. In terms lock, depth measurements are as important as width since they impact how securely the bolt is inserted into the host item. Also, dependency on the brand or lock cylinder is necessary to find replacement parts of the lock system.

- Installation: Install the lock based on the ease of accessing the locked area. For example, a rear spindle lock fits into the rear of the spindle assembly and may need screws through the lock housing into the door frame. After installation, a critical aspect of small box lock maintenance is ensuring proper lubrication for smooth lock operation and extension of its lifespan. Always use a high-quality lubricant. Check for signs of wear or damage occasionally, and replace as necessary, continuing optimal locking. Correctly stored keys in dry environments prolong key life and reduce wear or bending that may cause the key to snap when in use.

Usage scenarios of small box locks

Small box lock applications vary greatly, with storage and security needs of different industries and users driving their demand and use.

- Safes: In safety boxes, small box locks determine that money, documents, and other valuables are kept secure. These locks include combination and electronic locks which offer increased security over traditional key locks. As mentioned, safes usually made of heavy materials still feature internal components that can be easily damaged or hacked; hence, installing strong locking mechanisms is crucial.

- Cabinet locks: Small box locks frequently found in office and home furniture, mainly cabinets and drawers. For businesses, keeping sensitive documents locked away enhances confidentiality and, therefore, the safety of business information. In schools, libraries, or community centers, these locks might be used on lockers or storage units, preventing unauthorized access to materials that are intended for be kept secured. In such situations, key-retaining cam locks are commonly used, as they are easy to install and cheap.

- Tool boxes: Toolboxes and equipment cases use small box locks to keep tools and equipment secure from theft or loss. This security ensures that valuable, sometimes hazardous, tools remain protected when not in use. In construction sites, job workers leave expensive tools in locked boxes to avoid vandalism and pickpocketing. Combination or key locks are commonly found in mobile tool storage units.

- Vending machines: manufacturers of small box locks, particularly cam locks, widely apply these locks in vending and payphones. It ensures all products inside the machine are secure until the customer purchases something, therefore, increasing the company's hope of increasing its returned investment. These machines are accessed by service people for stock replenishment or money collection. The lock remains a safeguard against unauthorized access.

- Weapon storage: A secure medium box lock is vitally important for legal gun owners: it helps with the responsible storage of firearms and ammunition. A combination or key lock prevents unauthorized access by children or uninvited guests, thus enhancing safety while complying with regulations. Ammunition and firearm manufacturers typically advise using locked containers as an integral part of a security framework.

Q&A

Q1. How secure are the small box locks when compared to larger ones?

A1:Small box locks can be just as secure as larger locks, depending on their quality and type. However, larger locks offer more options in terms of advanced locking mechanisms, which may provide additional security.

Q2. Which key or combination retaining lock is most suitable for a safety box?

A2:Combination locks are most commonly used for safes because they offer security without the need to carry a key, which can be lost. Key locks also provide strong security for safes, especially in areas with less risk of theft.

Q3. What are the signs small box locks should be replaced?

A3:Some signs will make it evident that it's time to replace small box locks. They include physical damage, difficulties in lock or key operation, and compromised security, such as signs of tampering.

Q4. How often should small box locks be lubricated?

A4:Small box locks should be lubricated at least once a year or more often if they are used frequently or exposed to harsh environmental conditions.

Q5. What are the advantages of a keyless lock over a key lock?

A5:Keyless locks have the convenience of not needing a key, which can be lost or misplaced. Some keyless options feature electronic or combination methods, allowing easy reconfiguration for changing access needs.