(2183 products available)

Generally, the tool holder is a small part attached to the machine that holds the cutting tools. An example of such a part is the BT40 lathe tool holder.

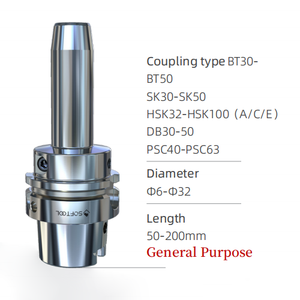

BT40 tool holders are spindle-end connector types that hold cutter shanks. The connector types typically include a tool holder, an integral tool holder, and a tool holder with a shank. The shank of these holders connects directly to the spindle of the machine.

An essential part of the BT40 tool holder is the collet. This part is used to grip the cutter tightly. It expands when it is inserted into a tapered sleeve. When the sleeve is inserted into the spindle, it contracts, gripping the cutter tightly.

Another important component of the BT40 tool holder is the keyway. The keyway prevents the tool from rotating inside the spindle. This helps in accurately positioning the cutter when the machine is working.

Variations of the BT40 tool holder exist, such as the BT milling tool holder and BT machine tool holder. Most BT40 tool holders are made of high-carbon steel due to its strength and durability. It can withstand various industrial environments and offer long-term service.

Things to look out for when choosing a BT40 tool holder are the tool type, workpiece material, machining precision, spindle connection, and diameter.

The spec of a BT40 holder can vary depending on the manufacturer, and tooling system applications, but here are some standard specifications that one should know.

Operating and maintaining the performance of the CNC holder is a crucial part of machine tool maintenance and management, which can ensure its precision, reliability, and lifespan. Here are some practical maintenance methods and suggestions.

Tool holders are used in many industries that employ lathes and CNC machines. The following are some industries or scenarios where BT40 tool holders may be applicable.

Metalworking shops

Design and metalworking shops may have machining operations as part of the design work. Such shops will use lathes with tool holders to create machined parts with integrated designs.

Machinery manufacturing

Machinery manufacturing often involves the production of large and complex parts that require high precision and accuracy for proper fit and function. Techs and engineers may also use CNC lathes to create component parts like bearings, gears, and shafts. They would need tool holders for the machine to hold the tools.

Aerospace and Automotive

Extreme precision is the hallmark of the aerospace and automotive industries. These industries require high-quality machining parts and components to ensure optimum machine functionality. The lathes in these industries work on various materials, including titanium and exotic alloys. Mechanisms often use BT40 tool holders for their CNC machines to facilitate the machining of engine parts, transmission components, and airframes.

Woodworking and Plastic Industries

These industries employ CNC routers and lathes to create high-precision joinery, cabinets, and furniture. Like the metalworking machines that use BT40 tool holders, wood and plastic machines may also use them or similar ones to hold cutting tools.

Medical Device Manufacturing

Medical device manufacturers use CNC machines to create surgical instruments, implants, and other medical devices. The machines work with high-precision tool holders to achieve the necessary accuracy and quality. If the machine uses the BT40 design, this is where the 40mm comes in. It may also be referred to as BT40 medical device tool holders.

Tooling and Fixturing

Some industries use CNC machines to create jigs and fixtures for other machines to aid the machining processes.

When choosing BT40 lathe tool holders, business buyers need to consider several factors.

Machine Compatibility

Initially, they need to ensure that the tool holder they select is compatible with their existing CNC machines. The tool holder's BT40 taper should match the spindle taper of the CNC machine. Additionally, the holder's length, diameter, and weight should be appropriate to avoid interference or balance issues.

Tools and Workpieces

Also, business buyers need to consider the types of cutting tools and workpieces their CNC machines will process. Different cutting tools require different tool holders. For instance, face mills need a specific holder, and selecting an improper one may reduce performance and damage the tool.

Material and Quality

Business buyers need to ensure that the tool holder material matches their specific needs, such as high-carbon steel or other materials with the same functions. Besides, buyers can generally choose between imported and domestic tool holders based on their budget and requirements. Tool holders with better quality and less damage to tools and workpieces can reduce overall maintenance and replacement costs.

End Use

The type of BT40 tool holder chosen will also depend on the end-use requirement. For machines that perform heavy-duty operations, buyers will need to select those with high rigidity and clamping force. On the other hand, for light-duty and high-speed applications, those with minimal tool change time and friction loss will be more suitable.

Q1: Which machine uses an R8 tool holder?

A1: A tool holder like the R8 is used in a spindle that has a conical form running a diameter of 3.25 inches. This specific design is found in many milling machines, including knee-type, offshore, and reiterative milling machines.

Q2: What is the difference between BT and SK tool holders?

A2: The primary difference between BT and SK tool holders is their physical characteristics. While both have identical taper angles, their flange diameters are distinct. Additionally, the holder's pole makes contact with the spindle mating surface, ensuring a secure fit.

Q3: What is the most common tool holder?

A3: The most common tool holder is the HSK, which has a short taper and high disc flange.

Q4: What are the advantages of tool holders?

A4: Tool holders provide many benefits. They aid in achieving accuracy and enhancing surface quality. They also assist in streamlining the production process, which boosts efficiency. Furthermore, they help maintain the repeatability and reliability of the machining process.