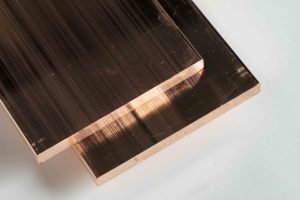

Understanding CCA Busbar

The CCA busbar, or Copper-Clad Aluminum busbar, plays a pivotal role in industrial electrical distribution systems. Known for its enhanced conductivity and lighter weight compared to pure copper, CCA busbars present an excellent solution for energy-efficient electrical installations. Specifically designed to efficiently carry current while minimizing losses, CCA busbars have become an essential component in high-performance electrical systems.

Types of CCA Busbar

There are several types of CCA busbars available, each tailored to meet specific electrical requirements and applications:

- Standard CCA Busbar: The most common type, designed for general electrical distribution in commercial and industrial settings.

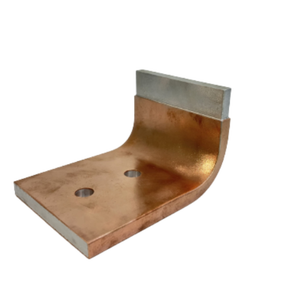

- Pre-drilled CCA Busbar: Features pre-drilled holes for quick and easy installation, ideal for retrofitting existing systems.

- Insulated CCA Busbar: Coated with insulation material to provide additional safety, used in situations where direct contact with conductive surfaces is a concern.

- Flexible CCA Busbar: Designed for applications requiring movement or flexibility, such as in robotic systems and certain types of machinery.

Applications of CCA Busbar

The versatile design of CCA busbars enables their use across a variety of sectors, including:

- Power Generation: Employed in transformers, substations, and renewable energy systems to conduct electricity reliably.

- Data Centers: Essential for high-density power distribution systems where space and heat management are critical.

- Industrial Automation: Utilized in assembly lines and manufacturing machines to facilitate efficient power supply.

- Transportation: Implemented in electric vehicles and rail systems for effective power management.

Key Features and Advantages of CCA Busbar

The CCA busbar boasts a range of features that confer significant advantages to users:

- High Conductivity: The copper cladding provides superior conductivity compared to pure aluminum solutions, resulting in lower energy losses.

- Lightweight: CCA busbars are considerably lighter than copper ones, making them easier to handle and install, especially in large-scale applications.

- Cost-Effective: The combination of aluminum's lightweight nature with copper's high conductivity offers economic savings while maintaining performance.

- Corrosion Resistance: Copper cladding naturally resists corrosion, ensuring longevity and reducing maintenance needs over time.

- Versatility: Suitable for a range of applications, CCA busbars can adapt to different operational areas, from industrial to commercial environments.