(1397 products available)

A CD cutter is a tool for cutting CDs and other discs. There are two main types of CD cutters: manual and electric.

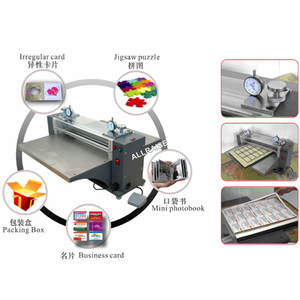

Electric CD cutter:

The electric CD cutter is a powerful machine with a motor. It is suitable for cutting large quantities of CDs. The motor drives the cutting blade, which makes cutting faster and easier. The cutting depth and speed can be adjusted to suit different needs.

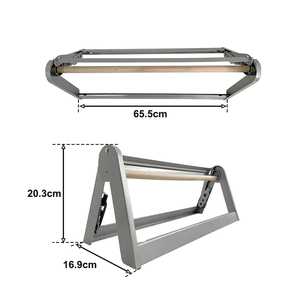

Manual CD cutter:

The manual CD cutter is a simple, compact machine. It has a hand-operated cutting blade. It is suitable for small-scale cutting tasks or for use in places with little space. The CD disc cutter is portable and easy to use. It usually has a simple design that allows the user to control the cutting process directly. Users can adjust the blade's position or move the cutting platform manually to achieve the desired cut. The manual CD cutter is more affordable than the electric one. It is cost-effective and easy to maintain, making it an economical choice for users with limited budgets.

Various designs of CD cutters are available to meet different demands.

Handheld CD cutters

Handheld CD cutters are small and portable. They are designed for manual use. They usually have a simple interface with buttons to start and stop the cutting process. The blade is often exposed to make the cutting process visible. Material like hardened steel or durable plastic usually makes the blade and body. The base of these CD cutters has features like non-slip surfaces or guides to aid accurate and clean cuts. They are ideal for situations where convenience and mobility are paramount.

Tabletop CD cutters

Tabletop CD cutters are larger and more complex than handheld ones. They often come with a more powerful motor to handle heavy workloads. They have a sturdy frame that minimizes vibration during operation for stability. The cutting mechanism is usually enclosed for safety, with a robust casing that protects users from accidental contact with moving parts. They offer advanced features like automatic blade return after use, making them safer and more user-friendly.

Laser CD cutters

Laser CD cutters use focused laser beams to cut CDs. These lasers can cut through various materials with high precision and clean edges. The design includes a laser assembly, optics to focus the beam, and cooling systems to prevent overheating during prolonged use. The software controls the cutting process, allowing for complex and detailed designs. They are used in applications that require intricate cuts or designs.

Industrial CD cutters

Industrial CD cutters integrate advanced robotics into their design. The robotic arms are precise and can move rapidly. They can cut CDs and perform other tasks, such as sorting and packaging. These machines are built to last and can operate continuously without compromising performance. They have redundant systems for reliability and safety. These CD cutters are used in factories where speed and efficiency are critical.

Music industry

CD jewel case cutters are important in the music industry for producing CDs with a variety of musical compositions. They are used for cutting and creating compilation albums and soundtracks for movies or shows. The cutters help to make the cutting process of multiple CD production fast and easy.

CD duplication business

CD duplication businesses that work with clients to produce copies of music or audio content find jewel case CD cutters very useful. In such businesses, CD jewel case cutters are used to create the original copy, which is then reproduced for clients. It makes the process of cutting jewel cases for CDs easy and quick.

Educational purposes

In educational institutions, educators can use CD jewel case cutters to make instructional materials for students. For example, they can produce and store educational videos, podcasts, and other audio materials on CDs using jewel cases made by the cutters. This enhances the learning experience and makes knowledge acquisition more impactful.

Archiving and preserving

Archiving institutions such as libraries and information centers that collect and preserve historical and cultural records can also use CD jewel case cutters. These institutions can use the cutters to produce CDs containing archival records and historical documents. This helps in the protection of these vital documents for future research and reference.

Personal use

Individuals who have collections of music or audio files can also use CD jewel case cutters for personal use. The jewel case cutters enable them to produce their own CDs and store them in self-made jewel cases. It also allows for the better organization of music files and gives room for the design of jewel cases in line with personal taste and preferences.

Purpose and Usage:

When selecting a CD cutter, users should consider the machine's intended purpose. Is it for personal use, small business, or large-scale production? A basic model may suffice for home use. In contrast, a small business might need a machine with higher speed and capacity. Large-scale production may require even more advanced features, so users should identify their primary needs before choosing a model.

Cutting Quality:

The quality of the cuts is another critical factor to consider when choosing a CD cutter. Users should look for a machine that can make clean, precise cuts. The quality of the cutting blades also affects the clarity and neatness of cuts. Users should opt for durable blades that maintain a good cutting quality over time.

Ease of Use:

The user-friendliness of the CD cutter is a vital consideration, especially for non-technical users. Look for a machine with a straightforward interface and easy-to-understand controls. Some models even provide touchscreen interfaces, making them easier to operate. Additionally, users should pay attention to features like blade adjustment mechanisms and paper feed systems, which can significantly affect the ease of use of the machine.

Durability and Build Quality:

The durability of the CD cutter and the quality of its construction also affect its service life and maintenance costs. Choose a machine made of high-quality materials that can withstand long-term use. Additionally, users should pay attention to the replaceability of the blades and the ease of maintenance, as these factors will also affect the total cost of ownership of the machine.

Cost:

The cost of the CD cutter is also an important consideration. Users should choose a machine that fits their budgets. However, choosing a machine solely based on cost may not be ideal because a more expensive machine may have better quality and features. Therefore, users should find a balance between cost and performance.

Brand and After-sales Service:

Finally, when selecting a CD cutter, users should pay attention to the brand and after-sales service of the product. Choose well-known brands that provide reliable product quality and after-sales service. After-sales service is crucial; it ensures users can get timely maintenance and support when needed. Additionally, users should pay attention to the warranty period of the machine and the availability of spare parts, as these factors also affect the long-term performance and reliability of the CD cutter.

Q1: What is a CD cutter machine?

A1: A CD cutter is a tool for cutting, shaping, and trimming CDs to achieve desired sizes or designs.

Q2: What are the types of CD cutter machines?

A2: The different types of CD cutter machines are manual, digital, and CNC CD cutters.

Q3: How does a manual CD cutter work?

A3: A manual CD cutter is a simple machine that works by applying human force to cut discs along predetermined lines using blades.

Q4: How does a digital CD cutter work?

A4: A digital CD cutter allows users to make cuts through buttons on its interface while using templates displayed on screens as guides.

Q5: What does CNC stand for in CNC cd cutters?

A5: CNC stands for Computerized Numerical Control in CD cutters.

Q6: What are the advantages of using a CD cutter?

A6: The advantages of using a CD cutter are cost-effectiveness, time efficiency, and accuracy, among others.

Q7: What materials can be cut using CD cutters?

A7: CD cutters can cut through various materials, including paper, cardstock, acrylic, and PVC.

Q8: How can one maintain a CD cutting machine?

A8: To maintain a CD cutting machine, its blades should be regularly sharpened, and debris must be cleared from the workspace. Oil must be applied to movable parts to ensure they function smoothly.