(32566 products available)

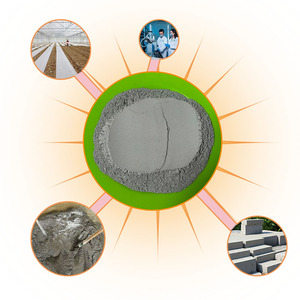

Cement is a fine powder that acts as a binder for aggregates and water to form concrete. It is used in construction because it hardens and stays put, even in wet conditions. There are three main types of cement aptly called Ordinary Portland Cement, Blended Cement, and Special Cements. Let's delve into them:

Coal is a combustible black or brownish sedimentary rock made of carbon-rich plant debris that has been subjected to heat and pressure over millions of years. It is the world's largest source of energy for electricity generation. There are four main types of coal, which include:

There are also other types of coals, such as coking coal, steam coal, and thermal coal, which are often referred to based on their uses rather than their characteristics.

Cement and coal both have important features and functions in construction that are critical to understand.

Binding Agent

Cement is a binding agent used in construction to make concrete and mortar. It binds aggregate materials together to provide structural stability. When water is added, the coal dust cement hardens into a rock-like mass that lasts for decades.

Compressive Strength

Cement has high compressive strength when used to make concrete structures like roads, bridges, and buildings. It can bear heavy loads without collapsing.

Versatility

Cement is versatile and used in various applications, including concrete, mortar, plaster, and grouts. This versatility makes it a preferred construction material.

Durability

Coal dust cement is durable when properly formulated and cured. Concrete structures last for decades, requiring low maintenance.

Workability

Cement-based mixtures have excellent workability. It is easy to shape, pour, and cast into any desired form or mold. This property is useful when constructing buildings.

Setting and Hardening

Cement has desirable setting and hardening characteristics. It provides enough working time to allow for proper placement and curing. Once set, it hardens gradually to reach optimal strength.

Coal as an Aggregate

Cement can be produced using pozzolanic materials like fly ash, silica fume, and slag. These materials are industrial by-products of power plants and steel manufacturing that use coal. They help reduce the need for traditional cement ingredients like limestone.

Sulfur Content

Some coals have high sulfur levels, which can weaken concrete if not controlled. Cement makers must use coal with low sulfur for better construction.

Calorific Value

Coal's calorific value measures its burning efficiency. Higher-value coals generate more heat, crucial for clinker production in cement kilns. Efficient heat helps create quality cement.

Globally, the demand for both coal and cement has skyrocketed. It is projected that this demand will continue to increase in the coming years. This is because both products are critical in various industries. As a result, many business buyers are looking for suppliers to meet their needs. Below is a list of buyers who could benefit from reading the report and is looking for suppliers:

Efficiency and emissions:

Efficiency and emissions are important considerations when choosing a coal for cement. Higher efficiency means more energy is produced per ton of coal burned, resulting in lower CO2 emissions. Some coal types, like PCI or bituminous coal, provide efficient burning with less waste in the cement kilns. They produce strong, consistent heat needed for high-temperature cement production while generating fewer emissions than lower-ranked coals.

Environmental regulations also impact efficiency and emissions. Plants must comply with local rules on sulfur, nitrogen, and particulate matter emissions. Selecting coals with low emissions profiles helps them meet those standards. Working with suppliers to analyze coal's environmental impact is crucial.

Cement demand and market conditions:

The demand for cement can influence the type of coal used. During high demand, cement manufacturers may opt for coals yielding high-quality, market-competitive cement products. In low-demand periods, coals that are cost-effective and efficient may be prioritized to lower production costs.

Market conditions like coal prices also affect coal selection. A lower-priced coal may be a preferred option if a particular coal becomes more expensive in the market. Understanding these dynamics helps manufacturers choose the suitable coal type under varying demand and market circumstances.

Availability and supply chain:

Availability significantly impacts the type of coal used for cement. If a particular coal is unavailable, manufacturers must find alternatives that work for their production process. A well-established supply chain also ensures consistent coal delivery. A reliable supplier can help mitigate risks of coal shortages or quality issues.

Geographical proximity to coal sources may reduce transportation costs and delivery time. Consider factors like transport infrastructure and logistics when selecting a suitable supplier.

Q1. What are the different types of cement?

A1. There are several cement types, including Portland, pozzolanic, oil well, rapid setting, and fly ash cement.

Q2. What is the role of coal in cement production?

A2. Coal is used to fuel cement kilns at high temperatures to produce clinker, the main ingredient of cement.

Q3. What is clinker?

A3. Clinker is a hard, lumpy material produced by heating limestone and other ingredients in a cement kiln. It is ground with gypsum to make cement.

Q4. How is coal converted to coke?

A4. Coal is coked by heating it in an oxygen-free environment at high temperatures. The process removes volatile compounds and moisture, resulting in coke.

Q5. What are the hazards of coal tar?

A5. Coal tar contains polycyclic aromatic hydrocarbons (PAHs), which are carcinogenic. It is a health hazard that must be managed appropriately.

Q6. What are the health risks of cement?

A6. Cement manufacturing and exposure to cement products have health risks. This includes burns from wet cement and respiratory issues from inhaling cement dust. Proper handling and safety precautions are important.