(1045 products available)

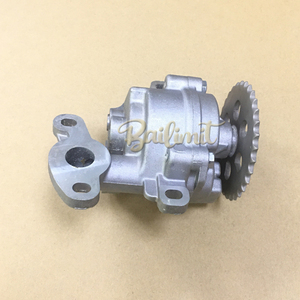

The oil pump is an important part of the car CG. It is in charge of siphoning oil from the oil repository and flowing it to the oil channels, guaranteeing that oil moves to all parts of the vehicle motor. There are a few sorts of oil siphons, each with its novel highlights and elements:

Gear oil pump

The cog oil siphon is the most widely recognized kind of oil siphon utilized in car motors. It comprises two interlocking rigging components encased in a chamber. At the point when the motor turns over, the pinion wheels pivot inside the siphon, making a vacuum that draws oil into the siphon from the oil repository. The movement of the pinion wheels pushes the oil out of the siphon and into the oil channels, guaranteeing a consistent progression of oil to all motor parts. The effortlessness and dependability of rigging oil siphons make them a famous decision for CG oil siphon applications. Moreover, there are two kinds of rigging oil siphons, in particular, inner apparatus oil siphons and outer apparatus oil siphons. Inward pinion gear oil siphons have their pinions in a siphon lodging. Then again, external rigging oil siphons have their pinions outside the siphon lodging. Contrasted with external pinion gear oil siphons, inward stuff oil siphons produce more tension and have more complex development.

Turbine oil pump

Another sort of CG oil pump is the turbine oil siphon. This sort of oil siphon is not quite the same as the gear oil siphon since it has a turning rotor as opposed to pinion wheels. The turning rotor in the siphon fills a similar capability as the stuff in the stuff oil siphon by drawing oil from the oil repository and pushing it into the oil channels. Turbine oil siphons produce more tension than rigging oil siphons, making them reasonable for high-pressure applications.

Rotary Vane Oil Pump

The rotating pinion oil siphon is another sort of CG oil siphon. The rotating element in the oil siphon comprises a round and hollow chamber with a pivoting pole and a few vanes. The vanes are mounted on the pivoting pole in a cut way, and they slide all through the siphon chamber divider. At the point when the pivoting pole turns, the vanes move all over the chamber, making vacuum and pressing factor changes. This component draws oil into the siphon and pushes it out into the oil channels. The rotating pinion oil siphon is a compelling oil siphon since it can create high vacuum and strain levels.

CG oil pumps come in different specifications and are manufactured using various materials to cater to different customer needs. Below are some common specifications of CG oil pumps:

Flow Rate

The flow rate of a CG oil pump is determined by the volume of oil it pumps in a minute. Depending on the application, the flow rate can be high or low.

Pressure Rating

CG oil pumps have different pressure ratings. The pressure rating is the maximum and minimum pressure the pump can handle.

Temperature Rating

CG oil pumps have different temperature ratings. The temperature rating is the maximum and minimum temperature the pump can handle.

Material

CG oil pumps are made of different materials such as cast iron, stainless steel, and carbon steel. The material affects the durability and the application of the pump.

Oil Type

Some CG oil pumps are designed to pump specific types of oil, depending on the viscosity. For instance, some pumps are designed to pump motor oil, while others pump hydraulic oil.

Pump Size

CG oil pumps come in different sizes. The size of the pump is determined by the flow rate and pressure rating.

Drive Type

CG oil pumps can be driven by electric motors, diesel engines, or be manually operated. The drive type of the pump depends on the application and the customer preferences.

Maintaining oil pumps is essential to ensure they last longer and operate efficiently. Here are some general maintenance tips for CG oil pumps:

Choosing the right oil pump for a vehicle requires careful consideration of several factors. Here are some tips:

Vehicle requirements

Read the owner's manual to know the specifications of the oil pump required for the vehicle. The manual will recommend the pump type, size, and flow rate to use.

Quality and reliability

Choose an oil pump from a reputable brand that is known for producing quality and reliable pumps. A good quality pump will last longer and ensure the engine gets the right lubrication.

Compatibility

Ensure the oil pump is compatible with the vehicle engine. Consider factors such as the engine type, modifications done to the engine, and other components like the oil filter and oil cooling system.

Installation

Consider how easy or hard it will be to install the oil pump. A pump that is easy to install will save time and money since it can be done quickly. Also, think about whether the pump can be installed without modifying other engine components.

Warranty and support

Look for an oil pump that has a good warranty period. This will protect the buyer in case of any defects. Also, consider the availability of customer support from the manufacturer or supplier.

Price

Oil pumps are available in a range of prices. Before purchasing one, create a budget based on the features and quality of the pump. Avoid very cheap pumps since they may be of poor quality.

Replacing the oil pump can be a complex task, but with the right tools and knowledge, it can be done. Here's a step-by-step guide:

Tools Needed

Steps

Q1: What is the warranty for CG oil pumps?

A1: The warranty period for the CG oil pump is between 6 and 12 months. Some suppliers offer a warranty of up to 18 months. Buyers can return the oil pump to the supplier if it has any manufacturing defects within the warranty period. The supplier will replace the oil pump or give a full refund. To get a replacement or refund, buyers must provide proof of the defect. Buyers should also read the terms and conditions of the warranty provided by the supplier.

Q2: Can a CG oil pump be repaired?

A2: It is difficult to repair a CG oil pump. When the oil pump develops a fault, the first step is to confirm that it is faulty. This is done by testing it in a lab. If the pump is confirmed to be faulty, it is recommended to replace it with a new oil pump. Replacing the old oil pump with a new one is more cost-effective than repairing. Furthermore, replacing the pump is safer because the vehicle will be protected from engine damage due to low oil pressure.

Q3: Can CG oil pumps be used in any vehicle?

A3: CG oil pumps are not suitable for all vehicles. Oil pumps are designed for specific engine types and sizes. For example, an oil pump designed for a petrol engine may not work in a diesel engine. Before buying, check whether the oil pump is compatible with the vehicle's engine.

Q4: Can CG oil pumps be used for old vehicles?

A4: CG oil pumps can be used for old vehicles. However, the oil pump must be compatible with the old vehicle. Buyers may need to place a special order to get an oil pump that is compatible with the old vehicle.