(1541 products available)

A band saw is a stationary or portable cutting machine that cuts materials using a long and continuous band or blade with teeth. Most band saws cut in straight lines, but they can also make curved cuts. Cheap band saws are commonly used to cut irregular shapes of wood or other materials. They are also popular for cutting hard metals into specific shapes and sizes.

Band saws have several advantages over other types of saws. For example, they can cut delicate curves with greater accuracy and leave better finishes without requiring additional tools. Band saws can also cut through thicker materials more easily and with less effort. All of these benefits mean that band saws are an invaluable tool for carpentry and metalworking.

There are two main types of band saws based on size and power:

A vertical band saw is a stationary machine with a saw blade mounted vertically. It is primarily used to cut curves in wood or other materials. When used for woodworking, vertical band saws may also be used for resawing and cutting irregular shapes. Vertical band saws usually have a larger cutting capacity than horizontal ones. This makes them better suited for cutting thick and tall workpieces with greater accuracy.

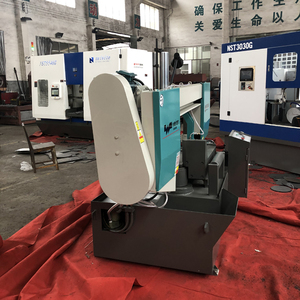

Horizontal Band Saw

Horizontal band saws are stationary or portable machines with a saw blade mounted horizontally. They are primarily used for making straight cuts. Although they are well-known for cutting metalwork pieces, band saws are also popular in woodshops to cut logs into planks and slabs. Horizontal band saws are great for making straight cuts through thick workpieces. They can also be used to make beveled and miter cuts with greater accuracy.

In addition to vertical and horizontal cuts, cheap band saws may be powered by electricity or be manual tools with a crank to guide the saw.

Cheap metal cutting bandsaw is very important for the construction, automotive, machinery, and furniture industries. In the construction sector, band saws help create roof trusses and window and door frames. The saws also cut concrete pipes and insulation panels. In the machinery and automotive industries, band saws cut large metal pipes, engine parts, metal sheets, and valve assemblies.

One of the most popular applications of band saws is in woodworking. Woodworkers use band saws to cut curves and rip lumber. It has become a go-to tool for carpenters, furniture makers, and craft enthusiasts. Beyond woodworking, metal band saws are popular in the construction industry, metal workshops, and automotive mechanics. They are used to precisely cut metal pipes, sheets, tubing, and valve assemblies.

Because of their versatility, cheap band saws are also used in the food industry to cut meat, fish, cheese, fruit, and vegetables. They help achieve clean and precise cuts with minimal waste. This somehow preserves the texture and integrity of the food.

In jewelry making and architecture, a cheap band saw can cut delicate materials like glass, gemstones, brass, copper, gold, and fine ceramics. Specialized band saws are used to make architectural models or prototypes. Other applications of a band saw include making barrels and cutting rubber. In the barrel-making industry, the saw is used to cut staves. This helps to increase productivity and efficiency. In the rubber industry, band saws are used to cut rubber sheets and strips. This helps to reduce manufacturing bottlenecks.

Choosing a cheap band saw requires careful consideration of various factors to ensure it meets specific cutting needs without compromising quality.

Cutting needs analysis

The first step in choosing a cheap band saw is to determine the specific cutting needs. Consider factors such as the types of materials that will be cut, the thickness of the material, and the cutting accuracy and precision required.

Size and capacity

When selecting a cheap band saw, it is important to consider the saw's size and capacity. The size of the band saw determines the maximum dimensions of the material that can be cut.

Blade selection

Check whether the band saw comes with a blade or requires a separate purchase. Some low-cost models may provide a trial blade that is not suitable for all applications. Research the required blades for specific cutting tasks and calculate their costs.

Build quality

Even when on a low budget, it is essential to prioritize the band saw's build quality. Consider the materials used in construction, such as cast iron or steel for the frame and table, as well as the precision of assembly and alignment.

Safety features

Although it is a low-priced option, it is still important to look for safety features like blade guards, emergency stop buttons and handrails. Safety should never be compromised, even when working with a limited budget.

User reviews and reputation

Before making a final decision, research user reviews and ratings of different cheap band saw models. Take note of common complaints and praise to understand the strengths and weaknesses of each saw.

Warranty and support

When buying a cheap band saw, it is important to consider the warranty and customer support offered by the manufacturer or seller. A reasonable warranty period can provide peace of mind in case of unexpected issues or defects.

Q1: Who makes saws for the cheap and affordable price?

A1: Several manufacturers around the globe make cheap bandsaw machine products at an affordable price. In some cases, it could be the same manufacturer who makes both the affordable and the more expensive models. The saw may have been designed to meet certain market demands or specifications to achieve a lower price.

Q2: Do all cheap bandsaws have tires?

A2: In bandsaws, the tires refer to the large, smooth wheels that are utilized to support the bandsaw blade. This is commonly found in larger bandsaw machines. In this machine, there will be two or more tires that are made from rubber or any other similar materials. The aim of this tool is to guide, support, and drive the blade so that it does not deviate from any cutting task. The cheap bandsaw may or may not have a tire depending on its size and function.

Q3: Are cheap bandsaw blades all the same?

A3: Cheap bandsaw blades are not all the same. Even if they look cheap and similar, they are manufactured in different ways and are made from different types of materials. The materials will include bi-metal, carbon, cobalt, and many more. Some may be designed for more professional usage and smoother cuts than others.