(2791 products available)

Ready to Ship

Ready to Ship

A clean foam swab is a small tool with a handle and a foam tip. It has many uses in cleaning and applying products. There are many types of foam cleaning swabs. Some of them are described below:

Buying clean foam swabs in bulk can be a daunting task when there are so many options available. Here are some things to look out for when choosing foam cleaning swabs:

Application

Consider the application for which the foam swab will be used. A precision cleaning foam swab is ideal if it is for general-purpose cleaning. Medical-grade foam swabs are best suited for medical applications. For cleaning electronic components, opt for fire-retardant foam swabs. Photography enthusiasts need to stock up on specialty foam swabs for sensor cleaning.

Foam density and firmness

Higher foam density means more cells packed into the foam head. Such swabs have a better cleaning action and are more absorbent. They also produce fewer particles and are gentle on delicate surfaces. Lower foam density swabs are more firm and are better for scrubbing applications.

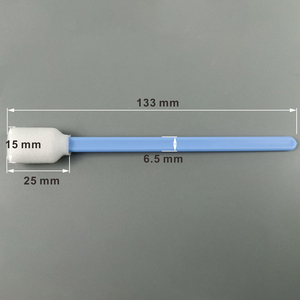

Size and shape of the swab head

Swabs come in rectangular, round, tapered, or pointed shapes. The size and shape of the foam head will determine how effectively it cleans a surface. For precision cleaning in tight spots, choose swabs with a tapered or pointed head.

Handle length and material

Foam swabs are designed with different handle lengths. Some have short handles, while others have long handles. Handles are made using various materials, such as plastic, wood, or metal. Consider the material used to make the handle, as it will determine the comfort when using the swab. Plastic handles are lightweight and offer a firm grip. Wooden handles are sturdy, but they are heavy compared to plastic handles. Metal handles are the best option if the swab will be subjected to harsh chemicals.

Packaging

Swabs are packaged in bulk or in smaller packs depending on the manufacturer. Buying in bulk is economical, especially if the swabs will be used for general-purpose cleaning. Consider the packaging material, as it will affect the storage of the foam swabs. Some packaging materials have a resealable option, making it easy to store the swabs and take them out when needed.

Clean foam swabs are easy to use and help keep all kinds of delicate surfaces free from dirt and residue. Their versatility makes them popular among different users, from DIY hobbyists to professionals working in laboratories or electronic manufacturing. Below is a brief overview of how to use and product safety guidelines.

Preparation

Start by identifying the surface or area that needs cleaning. This can be anything from electronic components, circuit boards, optical devices, or precision instruments. Gently approach the cleaning process by using a small foam swab. Don't apply too much pressure as this could transfer dirt instead of absorbing it.

Technique

Use light strokes when cleaning with the foam swab. Apply gentle pressure to avoid damaging sensitive surfaces. The tip should conform to the shape of the area being cleaned. Whether it's a narrow groove or a flat surface, allow the foam tip to collect dust and debris. Regularly check the foam tip during the cleaning process. If it becomes discolored or saturated, replace it with a new clean foam swab to ensure effective cleaning.

Post-Cleaning

After cleaning, visually inspect the surface to ensure all dirt, dust, or residue has been removed. If necessary, repeat the cleaning process with a new swab for stubborn spots. Dispose of the used foam swabs properly. Do not reuse them, as one of their main advantages is being single-use only.

Follow these steps to ensure safe use of foam swabs:

Read Labels and Instructions

Always read any labels or instructions provided by the manufacturer. Follow the recommended guidelines for safe use and disposal. This may include information on specific surfaces to avoid or precautions to take.

Surface Compatibility

Use foam swabs specifically designed for compatibility with delicate surfaces. Avoid using abrasive or harsh foam swabs on sensitive areas that may cause scratches or damage.

Gentle Pressure

Apply gentle pressure when cleaning. Excessive force can harm delicate components or surfaces. Allow the foam tip to do the work and collect dust and debris without pressing too hard.

Visual Inspection

Before using a foam swab, visually inspect it for any signs of damage or defects. Ensure the foam tip is intact and not torn or loose, as these may compromise the cleaning process and could leave residue or particles on the surface being cleaned.

Q1: What are the minimum order requirements?

A1: Different manufacturers have different minimum order quantities. Some can have MOQ of 1000 while other can go up to 5000 or more. The exact number will depend on the type of clean foam swab and the customization options requested by business buyers.

Q2: What customization options are available?

A2: Businesses can choose to customize the packaging of the clean foam swab. Some manufacturers also allow buyers to customize the length of the stick and the size of the foam head. This is important when ordering a swab for a specific medical application.

Q3: Does the foam head absorb liquid?

A3: Some foam heads are designed to absorb liquid. This feature is essential when using the swab for cleaning purposes. A foam head that does not absorb liquid will be more suitable for medical applications, as it will not leave excess liquid on the surface being tested.

Q4: What are the bulk packaging options?

A4: Businesses can receive clean foam swabs in bulk packaged in polybags, boxes, or bags. The packaging will depend on the order quantity and buyer preferences.