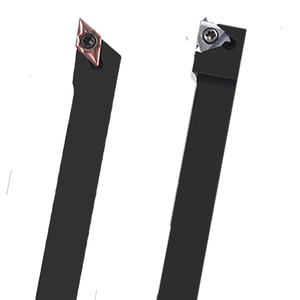

CNC Insert Tool Holder: An Overview

The CNC insert tool holder is an essential accessory in the realm of computer numerical control (CNC) machining. This tool holder is designed to securely hold insert cutting tools and facilitates precise machining operations in various industrial applications. Its superior grip and stability enable manufacturers to achieve exceptional accuracy and efficiency in their machining processes.

Types of CNC Insert Tool Holders

Understanding the different types of CNC insert tool holders can help manufacturers select the best fit for their specific needs. Here are the main types:

- Lathe Tool Holders: Used primarily for turning operations, these holders can accommodate various inserts for different materials.

- Milling Tool Holders: Designed for milling processes, they provide enhanced rigidity and versatility with a variety of insert shapes.

- Boring Tool Holders: Ideal for precision boring tasks, these holders support deep-hole drilling and adjustable insert positioning.

- Drilling Tool Holders: These are crafted to enhance drilling accuracy and extend the lifespan of the inserts used.

Applications of CNC Insert Tool Holders

CNC insert tool holders find applications across numerous industries, providing versatile solutions tailored to various machining needs. Notable applications include:

- Aerospace Manufacturing: Precision machining of aerospace components requires high-quality tool holders for exact tolerances.

- Automotive Engineering: Used to manufacture critical engine and drivetrain components, ensuring consistent performance and durability.

- Metalworking: Essential for fabricating metal parts, from small machined components to large automotive frames.

- Electronics Production: Ideal for creating intricate parts needed in electronic devices and circuit boards.

Features and Advantages of CNC Insert Tool Holders

The CNC insert tool holder showcases several features that contribute significantly to its performance, offering manufacturers undeniable advantages:

- High Precision: Ensures minimal runout and highly accurate machining operations, which translates to superior product quality.

- Robust Material Construction: Typically made from high-grade alloys or tool steels, providing durability and longevity.

- Ease of Use: Quick-change capabilities allow for rapid tool changeovers, minimizing downtime and optimizing productivity.

- Versatile Compatibility: Compatible with a wide range of inserts and cutting tools, enabling flexibility in machining different materials.

- Cost-Effectiveness: The ability to use replaceable inserts reduces tool costs without compromising on performance.