(46345 products available)

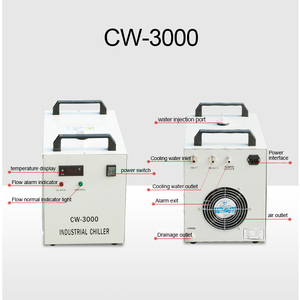

A chiller's control system regulates its functioning to achieve optimum performance while lowering operational expenses. Several sorts of chiller controls are commonly included with chillers, including electronic, pressure, temperature, flowmeter, humidistat, occupancy, event-based, combustion controls, and central control systems.

A control chiller regulates the temperature of a controlled environment or space. Such devices are crucial for numerous industry applications.

Industrial refrigeration and process cooling

Chillers are central to the food and beverage processing and manufacturing industries. Both industries require precise temperature control for optimal product quality and compliance with stringent regulatory standards. Control chillers consistently maintain the desired temperatures throughout food production, preserving the freshness of raw materials, preventing spoilage, and inhibiting the growth of harmful bacteria.

HVAC systems

Control chillers are a vital backbone of large commercial buildings, data centers, and industrial facilities. In such architectural and engineering systems, they regulate and control the temperature and humidity, offering indoor air that's cool, comfortable, and dry. This is especially important in commercial buildings, where optimizing employee productivity is a top business goal. In DPCI, control chillers help prevent the overheating of servers and other critical equipment to ensure business continuity.

Plastics and materials cooling

Control chillers play a pivotal role in the production of plastic products. In plastic injection molding, for instance, achieving rapid and uniform cooling of molded parts is essential for minimizing cycle times and maximizing production efficiency. By maintaining consistent temperatures during the cooling phase of molding, control chillers help prevent warping, reduce defects, and enhance the dimensional stability of molded plastics.

Laser and equipment cooling

Many types of lasers—medical, manufacturing, and scientific—rely heavily on control chillers for their proper functioning. Laser systems generate a significant amount of heat during operation. Control chillers remove that excess heat from the laser components to maintain optimal performance, prevent overheating, and ensure stable operation. Control chillers are also commonly used to cool various types of equipment in different industries. These can include electron microscopes, grinding machines, and RF plasma generators.

Pharmaceuticals and biotech

Control chillers are critical for the pharmaceutical and biotechnology industries. Temperature control is crucial for maintaining the integrity of products such as pharmaceuticals, biological samples, and chemicals. Control chillers provide the precise cooling necessary for processes like fermentation, extraction, and chromatography. Additionally, control chillers help regulate the temperature of storage facilities, ensuring that drugs and sensitive materials are kept within specified temperature ranges.

Cleanroom cooling

Control chillers are essential for cleanroom environments found in industries such as semiconductor manufacturing, biotechnology, and pharmaceuticals. Cleanrooms require strict control of temperature and humidity to minimize particle contamination and create optimal operating conditions. Control chillers enable the precise control of cooling systems that regulate temperature and humidity levels in cleanrooms, contributing to product quality and compliance with cleanroom standards.

BothAir-cooled chiller controland water-cooled chillers are popular options for many industrial plants. Here are some tips for choosing a suitable industrial chiller for the control of a specific industry.

Cooling capacity

This is the amount of heat the chiller can remove from the process per unit of time, usually expressed in kW or BTU/hr. It is important to select a chiller whose cooling capacity matches the heat load of the process to ensure optimal performance and efficiency.

chiller control type

It can be programmed to maintain constant cooling temperature or adjust cooling capacity based on changes in heat load. There are advantages and disadvantages to both preset and programmable controls, so it's important to consider the specific needs of the application before choosing a chiller control.

Refrigerant type

Common refrigerants include R22, R410A, R134A, and R407C. The choice of refrigerant can impact the chiller's efficiency, environmental impact, and legal compliance.

Operating environment

The environment in which the chiller will be operating, including factors such as ambient temperature, humidity, and exposure to corrosive substances, can also influence the selection of the chiller. These are factors that need to be considered when choosing a refrigerant. For example, air-cooled chillers may be more suitable than water-cooled chillers in an environment with limited water availability.

Energy efficiency

It is important to consider the energy efficiency of the control chiller, as it can impact operating costs and environmental impact. Look for chillers with high energy efficiency ratings and consider factors such as the cooling capacity-to-power ratio and operating reliability.

Regulatory compliance

Control refrigerants must comply with various environmental regulations, such as those related to ozone depletion. It is important to consider the machine's regulatory compliance and choose a refrigerant that meets the applicable legal requirements.

Q1: How do industrial chillers control the temperature of air?

A1: Using the refrigerant, industrial chillers control the temperature of air by cooling a secondary fluid, such as water or ethylene glycol, which then circulates through coils or heat exchangers. Heat from the air is absorbed into the chilled fluid, which removes the heat from the space.

Q2: What is the difference between a chiller and a cooler?

A2: A chiller is a machine that is designed to cool a liquid, which is then pumped through the coils of air cooling products such as air conditioning units. A cooler refers to a device that cools down the temperature of a specific product or substance.

Q3: Do controllers in chillers need to be replaced?

A3: The controller in a chiller does not typically need to be replaced, but it may need to be repaired or replaced if it is damaged or malfunctions. If there is a need for upgrade or improvement of the chillers' functionality, it may be necessary to replace the controller.

Q4: Can a chiller be controlled remotely?

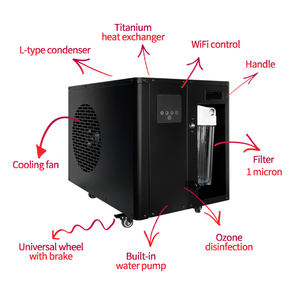

A4: It is possible to control a chiller remotely, but this is dependent on the specific model and its features. Some chillers are manufactured with remote monitoring and control capabilities, allowing users to remotely adjust the chiller's settings, monitor its performance, and receive alerts and notifications related to its operation.