(136723 products available)

![[JT-ML1040]CE Die Cut Label <strong>Machine</strong> Rotary Die Cutting <strong>Machine</strong> <strong>Craft</strong> Buddy Mini Die Cutting <strong>Machine</strong>](http://s.alicdn.com/@sc04/kf/H5f71520462494c288b1eb8fcf5886036d.jpg_300x300.jpg)

![[JT-ML1040]CE Die Cut Label <strong>Machine</strong> Rotary Die Cutting <strong>Machine</strong> <strong>Craft</strong> Buddy Mini Die Cutting <strong>Machine</strong>](http://s.alicdn.com/@sc04/kf/H79f4f5df222449268abf288b30800046h.jpg_300x300.jpg)

![[JT-ML1040]CE Die Cut Label <strong>Machine</strong> Rotary Die Cutting <strong>Machine</strong> <strong>Craft</strong> Buddy Mini Die Cutting <strong>Machine</strong>](http://s.alicdn.com/@sc04/kf/H6c7b2bd3a0404c8e9d74a19cf2108745d.jpg_300x300.jpg)

![[JT-ML1040]CE Die Cut Label <strong>Machine</strong> Rotary Die Cutting <strong>Machine</strong> <strong>Craft</strong> Buddy Mini Die Cutting <strong>Machine</strong>](http://s.alicdn.com/@sc04/kf/Hb2326a79fa2642179306fb50d32540abp.jpg_300x300.jpg)

![[JT-ML1040]CE Die Cut Label <strong>Machine</strong> Rotary Die Cutting <strong>Machine</strong> <strong>Craft</strong> Buddy Mini Die Cutting <strong>Machine</strong>](http://s.alicdn.com/@sc04/kf/Hd20131d20b1243719b35d1ccbc6293c4e.jpg_300x300.jpg)

![[JT-ML1040]CE Die Cut Label <strong>Machine</strong> Rotary Die Cutting <strong>Machine</strong> <strong>Craft</strong> Buddy Mini Die Cutting <strong>Machine</strong>](http://s.alicdn.com/@sc04/kf/H0acda714d11e4b3489c6dd66f8a562beC.jpg_300x300.jpg)

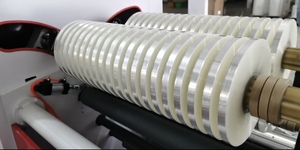

A craft machine is an automation device that helps DIY enthusiasts and crafters create digital designs for various types of materials. The machines can cut, draw and engrave, among other processes. One of the most common types of craft machines is the cutting machine. A cutting machine can use the blade or no blade approach to cut through materials that can be used in a specific project.A cutting machine with a blade typically works by identifying the correct starting point for the cut. The machine then moves its blade to the designated starting point before pressing down to make the required cuts. The blade then moves around the material until it makes the required cuts, after which it returns to its original position.Able cutting machines operate without a blade. They work by using a laser to cut through space and make a particular shape. They work similarly to cutting machines with blades. However, the main difference is that a laser is used to burn or cut through the material instead of a blade. Laser cutting machines are usually more accurate than blade cutting machines and allow for more complex designs. A laser cutting machine can make multiple cuts without the need to stop and change blades.

It is important to regularly maintain the craft machine to get optimum performance and prolong its lifespan. Lack of maintenance could render the machine useless very quickly.

Crafters use the devices for various applications and scenarios that require personalized or unique items. The machines can efficiently make the following:

Decals and Stickers:

Both professional and hobbyist craft machines can cut vinyl decals and stickers for personal use or to sell. Social media marketers can use stickers to promote a brand. They can also create unique stickers for products or give a branded sticker as a business card.

Custom Apparel:

A crafting machine can help create heat transfer vinyl (HTV) designs and custom vinyl items. Some items include T-shirts, bags, and hats. Designers can use the machine to make personalized clothing, uniforms, or event merchandise with logos, slogans, or artwork.

Personalized Home Decor:

A craft machine can be used to cut out unique designs and vinyl wall art. Users can use it to create professional-looking decals to use on windows, walls, laptops, or other hard surfaces. The crafted vinyl decals can also be a great gift for people to use for home decoration purposes.

Gift Tags and Labels:

A craft machine can be used to make customized gift labels and tags for presents. With the help of an identifier, users can effortlessly personalize tags for events, shipments, jars, or items. The labeled gift can make a present more thoughtful and personal.

Unique Cards and Invitations:

Die-cutting machines are great for embossing, cutting, and personalizing cards or making invitations. The scenario works well for weddings, birthdays, holidays, or corporate gatherings.

Other popular applications that a craft machine can make include:

When selecting a craft machine for resale, consider the most important attributes such as the capacity of the machine, its cutting technology, how user-friendly it is, connectivity options, and the quality and quantity of materials it can handle.

Work capacity

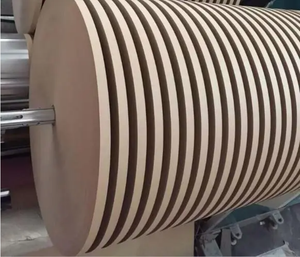

Before choosing a machine to sell, it is wise to first consider its work capacity. This includes the maximum number of tasks it can perform in a period. Retailers should look for machines with high work capacity. This way, the customers will not experience any issues like machine overheating or breakdowns. Additionally, it is important to look at the cutting size capacity. Customers with larger scale projects will often look for machines that can accommodate large sizes.

Cutting technology

A variety of craft machines are available, all with different cutting technologies. When selecting a machine for resale, it's wise to consider its accuracy, versatility, and precision. Laser cutting machines are often favored by customers because of their high precision cutting. They also have the ability to make complex cuts. Additionally, laser machines are very easy to use. On the other hand, blade cutting machines are appreciated for their versatility. They are able to cut through a larger variety of materials. They also have the capacity to take on different types of projects.

User-friendly

User friendliness is an essential factor for retailers to consider when selecting a craft machine. An easy-to-use machine comes with an intuitive interface and clear instructions. Such machines are ideal for all users, including those who are new to crafting. When selecting a machine to sell, consider its software compatibility and project library. Machines with helpful software and a large project library are ideal because they help users plan their projects with ease.

Connectivity options

Most customers prefer a craft machine with many connectivity options. Such options help the machines to connect with various devices with ease. Retailers should look for machines with Bluetooth and Wi-Fi capabilities. This allows customers to enjoy a wireless and easy integration experience. Also, consider how easy it is to connect the machine to a computer, smartphone or tablet. Machines with easy plug-and-play capabilities are ideal to sell. Such machines allow customers to enjoy quick and easy setup.

Material compatibility

Buyers often look for a craft machine with a wide range of material compatibility. Such a machine enables them to explore various projects and types of creativity. When looking for a machine to sell, consider one that can handle regular crafting materials like paper and cardstock. Also, a good machine provides a smooth cutting experience for more unique materials like leather and fabric.

Q1: What types of materials can a craft machine cut?

A1: Most devices are designed to work with various types of materials ranging from paper and cardstock to vinyl and iron-on transfers. Some advanced machines can even handle fabric, foam, leather, and wood.

Q2: What is the maximum cutting thickness of a craft cutting machine?

A2: The maximum thickness varies from one device to another. However, most machines can cut materials that are approximately 1 mm thick. Please check the specifications for details on the maximum cutting thickness.

Q3: Can a craft cut machine engrave materials?

A3: While engraving is not a primary function of most devices, some models offer engraving capabilities or work with engraving attachments.

Q4: Can a craft cut machine print materials?

A4: The ability to print varies from one model to another. Some advanced models come with a printing feature, while others need to be attached to a printer.