(209 products available)

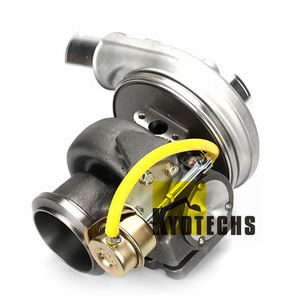

The D7 D turbocharger is a high-pressure and high-flow turbocharger that can be used on many engines. Usually, it is used on a D7D engine. The D7D turbocharger is mainly used on heavy-duty trucks, and it is a key part of the D7D engine. The D7D turbocharger improves airflow into the engine, which improves engine performance and fuel efficiency.

The D7D turbocharger has different types, including:

D7 Volvo turbocharger

The D7 Volvo turbocharger is a turbo used on Volvo trucks. The D7 Volvo turbocharger helps improve the performance of the D7D engines.

D7 MAN turbocharger

The D7 MAN turbocharger is a turbo used on MAN trucks. The D7 MAN turbocharger helps improve the performance of MAN trucks.

D7 Renault turbocharger

The D7 Renault turbocharger is a turbo used on Renault trucks. The D7 Renault turbocharger helps improve the performance of Renault trucks.

D7 Scania turbocharger

The D7 Scania turbocharger is a turbo used on Scania trucks. The D7 Scania turbocharger helps improve the performance of Scania trucks.

D7 Iveco turbocharger

The D7 Iveco turbocharger is a turbo used on IVECO trucks. The D7 Iveco turbocharger helps improve the performance of the D7D engine.

Regular Oil Changes

The turbo relies on engine oil for lubrication. Changing the oil regularly prevents dirt buildup and ensures proper oil flow to the turbo. Follow the recommended schedule in the owner's manual. For most cars, this is every 5,000 to 7,500 miles. Use a high-quality oil that meets the specifications in the manual.

Use Quality Replacement Parts

If any part of the turbo needs replacing, use components that meet or exceed the original specifications. Avoid cheap knockoff parts that could fail quickly. Genuine OEM or high-quality aftermarket parts provide the reliability the turbo needs. Inspect the wastegate, actuators, and other valves regularly.

Inspect and Clean Intercooler and Piping

The intercooler cools the compressed air from the turbo before it enters the engine. Over time, oil residue can build up in the intercooler and piping, reducing efficiency. Periodically remove the intercooler and clean it thoroughly. Also, inspect the piping for leaks or damage. A problem here means less boost reaches the engine.

Monitor Boost Pressure

Many vehicles have a boost gauge on the dashboard. This tells how much air the turbo is forcing into the engine. If the needle suddenly spikes or drops, there could be a problem. Too much boost can damage the engine over time. Too little means less power. Either case requires investigating what's wrong with the turbo or related parts.

Inspect the Exhaust System

The exhaust flows out of the engine, through the turbo, and then the downpipe. A restriction here means less efficiency and power from the turbo. Periodically check for issues like dents, rust, or a clogged catalytic converter. Also, listen for strange noises that could signal a problem.

Check Turbo Gaskets and Flanges

The gaskets and flanges connect the turbo to other parts like the exhaust manifold and downpipe. Loose bolts can cause exhaust leaks, which hurts turbo performance. Carefully inspect all gaskets and flanges for signs of wear or damage. Retighten bolts as needed.

Schedule Professional Inspections

In addition to at-home checks, take the vehicle to a mechanic for periodic turbo diagnostics. They have specialized tools to thoroughly test turbo components. A pro can catch potential issues before they cause major problems. Follow the maintenance intervals recommended in the owner's manual.

Understand the Engine Requirements

Each engine has specifications that dictate which turbocharger will perform best. Consider the engine's size and type, its power needs, and how it usually runs (like driving styles or load conditions). This matches the turbocharger to the engine for optimal performance.

Consider D7 D Turbocharger Size

Turbochargers come in various sizes. A smaller turbo spools (starts spinning) quickly but may run out of breath at high RPMs (revolutions per minute). A larger turbo takes longer to spool but offers more power at higher RPMs. The D7 D turbocharger size should balance needs based on driving habits, the vehicle's use, and the desired power band.

Assess D7 D turbocharger D7 turbine and compressor wheel dimensions

The turbine and compressor wheel dimensions impact airflow and pressure. A bigger compressor wheel means more air and higher pressure but needs more energy to spin. This could lead to turbo lag. The right-sized wheels match the goals for power delivery and efficiency.

Evaluate D7 D turbocharger D7 ratio

The aspect ratio affects the turbo's speed and how it boosts power. A higher AR suits high power at low heat, while a lower AR gives a quick spool time but less power. Pick an A/R ratio that aligns with the desired balance of characteristics in the vehicle.

Consider Material Choices

D7 D turbochargers use various substances. Cast iron is strong but heavy. Stainless steel is corrosion-resistant. Inconel and titanium are great for high heat but cost more. The material impacts how long the turbo lasts, how it handles heat, and the budget.

Evaluate Bearing Systems

The bearing system is vital for how smoothly the turbo spins. D7 D turbochargers can have journal bearings, which are standard and affordable, or ball bearings, which are pricier but reduce turbo lag and allow it to spin faster. Think about the driving needs and how much to spend when choosing.

Assess D7 D turbocharger cooling methods

A cooled turbo lasts longer and performs better. Look for D7 D turbochargers with oil cooling to take heat away. Water cooling is even better at managing high temperatures. Cooling matters if pushing the vehicle's limits or driving hard.

Research the Manufacturer's Reputation

Find a D7 D turbocharger maker with a solid track record. They should offer a warranty and good help if issues arise. Check reviews to see what others say about the company's quality and service. A reliable brand stands behind its products.

Consider the D7 D turbocharger warranty

A warranty shows the maker trusts their work. Look for an extended warranty period, which means the company stands behind how well the turbo works over time. A solid warranty protects the investment in case of problems.

Installation and Maintenance

Proper installation and upkeep are critical for turbo performance and durability. Either select a turbo that is simple to install and maintain, or be ready to pay extra for expert installation and recurrent maintenance. This guarantees the turbo works well day-to-day.

Replacing the D7D turbocharger is a complex process that requires careful attention. Here are the steps for replacing a D7D turbocharger:

Safety Precautions:

Before starting the replacement process, ensure that all safety precautions are observed. Disconnect the vehicle's battery to prevent any electrical accidents. Allow the engine to cool down to avoid burns when working with the engine components.

Gather Necessary Tools:

For replacing the D7D turbocharger, ensure to have the right tools. These include socket sets, wrenches, pliers, a torque wrench, and an oil drain pan. It is also important to have the new turbocharger ready for installation.

Drain Engine Oil:

Once the right tools are in place, drain the engine oil. Place the oil drain pan underneath the engine's oil pan and remove the oil drain plug. Allow the oil to fully drain before proceeding to the next step.

Remove Exhaust and Intake Connections:

Start by disconnecting the exhaust pipes connected to the old turbocharger. Also, disconnect the intake pipes that connect the turbocharger to the air intake system. These connections may be secured with bolts or clamps, so use the appropriate tools to loosen and remove them carefully.

Disconnect Oil Lines:

Oil lines are important components of a D7D turbocharger as they supply oil to the turbo for lubrication and cooling. When replacing a D7D turbocharger, disconnect the oil lines. Use pliers to loosen the clamps securing the oil lines and carefully remove the lines from the turbocharger. Be prepared for some oil residue to drain from the lines during removal.

Unbolt and Remove the Old Turbocharger:

The final step is unbolting and removing the old turbocharger. Use a socket wrench to remove the bolts securing the turbocharger to the engine exhaust manifold. Once all the bolts are removed, carefully lift the turbocharger out of its mounted position and set it aside.

Install the New Turbocharger:

Take the new D7D turbocharger and position it carefully onto the engine's exhaust manifold. Secure it in place by tightening the bolts using a socket wrench. Ensure the turbocharger is properly aligned to avoid any leaks or damage.

Reconnect Oil Lines:

After installing the new turbocharger, reconnect the oil lines. Ensure the lines are connected securely to prevent any oil leaks. Use pliers to tighten the clamps firmly.

Reinstall Exhaust and Intake Connections:

Once the oil lines are reconnected, reinstall the exhaust pipes to the turbocharger. Ensure all connections are tight and secure to prevent any exhaust leaks. Also, reinstall the intake pipes, connecting the turbocharger to the vehicle's air intake system.

Reconnect the Vehicle's Electrical System:

Reconnect any electrical connections that were disconnected from the turbocharger or related components. Ensure all connections are secure and properly connected.

Refill Engine Oil:

Once the electrical connections are reconnected, refill the engine with oil. Remove the oil fill cap and pour the recommended amount of oil into the engine. Replace the oil fill cap securely.

Check for Leaks and Test the Turbocharger:

Before starting the engine, thoroughly inspect all connections, including oil lines, exhaust pipes, and intake pipes, for any signs of leaks. Ensure all connections are secure and leak-free. Start the engine and allow it to idle for a few minutes. Monitor the turbocharger's performance and listen for any unusual noises or issues.

Q1: What is the D7 Turbocharger?

A1: The D7 turbocharger is a turbocharger used in various engines to improve performance and efficiency.

Q2: How does the D7 turbocharger work?

A2: The D7 turbocharger uses exhaust gases from the engine to spin a turbine, which in turn spins an air compressor. This process forces more air into the engine, allowing it to burn more fuel and produce more power.

Q3: What are the benefits of using a D7 turbocharger?

A3: Using a D7 turbocharger offers several benefits, including increased engine power, improved fuel efficiency, and reduced emissions. The D7 turbocharger allows the engine to produce more power without using extra fuel, which helps in burning the fuel completely, hence reducing emissions.

Q4: Can any engine be equipped with a D7 turbocharger?

A4: In principle, any engine can be fitted with a D7 turbocharger. However, the installation must be correctly designed and executed for the specific engine type to ensure compatibility and optimal performance.