(5362 products available)

There are several types of design lubricants available on the market today. These are intended for a wide range of applications to accommodate different requirements. Below are the most demanded, categorized according to the material and purpose they serve.

Water-Based Lubricants

Water-based lubricants are preferred due to their ease of use and compatibility with various materials. These lubricants, which feature a primary water content, have a thickening agent and other functional additives to enhance their viscosity and lubricating properties. Being easy to clean and non-greasy, water-based lubricants are ideal for sensitive applications such as food processing or medical equipment. Also, the water-soluble grease they provide is especially important where non-toxic, easy-to-remove substances are necessary.

Biodegradable Lubricants

Biodegradable lubricants are a green alternative for people looking to reduce their environmental impact. These are made from renewable resources. For instance, plant-based oils or synthesized substances designed to break down naturally over time. Biodegradable lubricants work well in farming, forestry, and even marine operations. Areas where the grease's contact with soil or water is basically unavoidable and where the grease's lubricant lifespan is shorter, are ideal for these lubricants.

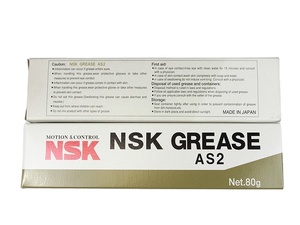

Specialty Lubricants

Specific lubricants are made to perform well under certain requirements. For instance, high-temperature lubricants withstand temperatures and are used in industries like metallurgy and glass production. Anti-corrosion lubricants protect parts exposed to water and other damaging elements. These lubricants are often used in areas with extreme working conditions and thus need unique protection. They can also extend product lifespan and maintenance frequency.

Oil-Based Design Lubricants

These oil-based design lubricants are manufactured using mineral or synthetic oils and deliver durability and flexibility. They reduce friction very well and are also very effective on surfaces that have high contact and under heavy loads. One downside is the water-based lubricant's biodegradability, as they aren't easily biodegradable and could potentially harm the environment if not properly disposed of. However, with their durability and efficiency, oil-based lubricants remain the go-to solutions for many industries.

Graphite and Other Solid Lubricants

Graphite lubricants, as well as other solid lubricants such as molybdenum disulfide, are powdery substances that provide lubrication even in extreme conditions. They do not disappear like liquid greases and oils, which makes it possible for them to work in extremely high-temperature settings or with substances that have high vacuum levels where oils are no longer acceptable. Solid lubricants are often applied in aerospace, military, or high-heat mechanical applications.

The proper type of industrial model grease is manufactured to fit a wide range of application needs, as shown below.

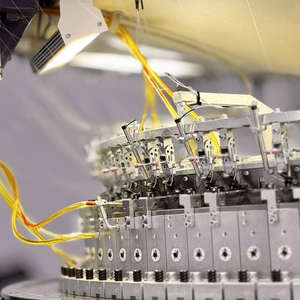

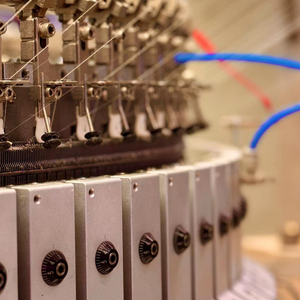

Manufacturing Industry

Design lubricants play a critical role in minimizing friction and wear between the components of machines. Such lubricants are used in machine parts, conveyor belts, and tools in the manufacturing industry. For instance, in the automotive manufacturing industry, lubricants are utilized to ensure the smooth functioning of the machine as well as to improve the durability of the components. Further, with the introduction of energy-efficient design lubricants, manufacturers are able to lower their operational costs as well as have an eco-friendly practice.

Agriculture

Greases and oils areused quite often in farming equipment. Such equipment includes tractors and plows. The lubricants protect the wear and tear of the machinery used during the harsh conditions that are commonplace in farming. With the help of water-soluble greases, the maintenance of this equipment becomes much easier, especially in cleaning and servicing the parts of the machines that are in contact with food. In addition, lubrication enhances the workability of equipment and thus reduces frequency and severity, as well as increasing productivity.

Marine Industry

Lubricants in offshore and ship repair help resist seawater's corrosion and extreme temperatures. These are also applied to ship engines, propellers, and gears. Furthermore, because the marine environment has extremely high lubricating demands, it needs more robust and reliable lubricants, which is why the design lubricants used in this application are specially formulated with anti-corrosive and water-resistant additives. They go a long way in extending the lifespan of marine equipment and also reduce how often it needs maintenance.

Renewable Energy

Lubricants are critical to the functioning of wind turbines and other renewable energy systems. For instance, parts of the turbine have to be lubricated to minimize friction and have smooth rotation. The design lubricants used in this context are eco-friendly and biodegradable, reducing the chances of pollution if the lubricant leaks. In addition, these lubricants enhance the efficiency and reliability of renewable energy technology, which is a huge advantage for the green energy sector.

Construction Industry

Grease and lubricants are applied to a variety of construction machines. Equipment, including excavators, bulldozers, and loaders, work under some of the most challenging circumstances, and lubrication is critical for its durability. Water-soluble greases are easy to clean and reapply, so they're great for on-site maintenance. Further, special design lubricants are applied to seals, joints, and bearings to minimize wear and increase energy efficiency in this industry, which works extensively and sometimes in extremely adverse conditions.

Compatibility

The design lubricants must be compatible with the type of material and equipment being used to guarantee performance and protect against damage. This mainly applies to parts that are made from specific materials like plastics or metals since some lubricants could degrade these materials. Further, if the equipment involves food processing or medical equipment cleaning, the lubricants must be safe and ideally water-soluble just for ease of cleaning. Lubricants can also affect seals, gaskets, and other components made of specific materials, thus ensuring compatibility. For optimal functioning, always have corresponding water-based or solids next to the equipment and parts.

Operating Conditions

Ideally, the lubricants should be able to meet the specific demands of the environment in which they are meant to operate. Tolerance to temperature extremes, resistance to corrosion, and capacity to handle different loads and speeds are all vital considerations. Marine and outdoor design lubricants, for example, must be able to resist water and dust. At the same time, lubricants used in manufacturing should be able to tolerate chemicals that are commonly used in the manufacturing process. If the equipment operates at high temperatures, high-viscosity lubricants may be better in such circumstances as they tend to flow less under heat.

Environmental Impact

"Going green" or"thinking green" is now the new norm when it comes to choosing design lubricants. Biodegradable options are preferable for people working in agriculture, forestry, or other businesses where grease can easily come into contact with soil or water. Even in industries where the likelihood of an escape occurrence is low, the use of lubricants with low toxicity is encouraged because they could end up in the environment one way or another. Using water-soluble grease is a simple way to ensure leaks or spills cause minimal pollution because it can easily be washed away.

Performance and Longevity

It is also worth considering how effective and, ideally, how long the lubricant will last under the conditions expected. Measurements of efficiency include factors such as friction reduction and wear, while longevity refers to the period during which the lubricant will maintain its efficacy. In how long they last lubricants are critical to operations in industrial settings since downtime brings about huge financial losses. When endurance and efficiency are considered, special lubricants are designed for performance or longevity, depending on what is more required in the process.

Cost-Effectiveness

This does not necessarily mean that the cheapest option is the best. However, looking for design lubricants that provide the best performance for the cost incurred is important. Longer-lasting lubricants are likely to save more in the long term, even if, initially, they may be more costly.

Regular Monitoring

The first and very important step in lubricant maintenance is conducting regular checks. These involve the actual physical observations of lubricant levels, consistency, and color, as well as other signs of contamination or degradation. In addition to these visual checks, monitoring operating conditions of the equipment where the lubricants are applied helps ascertain if the lubricant is performing as expected. One such example is when the equipment experiences abnormally high friction or overheating: it could be a sign that the lubricant has broken down or that there is an inadequate amount of it.

Contamination Control

"Contamination control" is one of the vital aspects of lubricant maintenance. Lubricants can be contaminated by dust, water, and debris, affecting their performance. Ideally, proper sealing and filtration should be installed to prevent such occurrences as much as possible. When water-based lubricants are contaminated and cannot be efficiently cleaned, it is imperative to go for methods that will ensure it is either disposed of or decontaminated effectively. Contaminated lubricants not only degrade the equipment but also increase its resource needs.

Replacement and Recycling

Replacement of lubricants is necessary for the bearings to operate optimally. How often they are replaced depends on how well they have been maintained, their operating conditions, and the users' requirements. Users don't have to replace lubricants like biodegradable and water soluble greases all the time since they can effectively be cleaned and reused. Recycling lubricants may also be possible depending on the kind of technology used to produce them.

Keeping Lubricants Clean

To improve the efficiency of design lubricants, it is important to keep them as clean as possible so that they can serve their purpose effectively while increasing the lifespan of the equipment. Cleaning can be done by implementing effective filtration systems that can remove all the contaminants that are in the lubricants. Preventing exposure to dust, chemicals, and water goes a long way in assuring the cleanliness of this substance. Besides, regular checks and monitoring go a long way in improving the performance of the product.

Proper Disposal Methods

"Disposable" here does not necessarily mean it can be thrown away anyhow. It's very important to dispose of lubricants, especially those that could be harmful to the environment, properly so as not to cause pollution. For example, water-soluble grease can easily be disposed of because it is biodegradable. However, still, there are rules and regulations concerning it, and they must be followed. Oil-based lubricants should first be taken to collection centers where they can be processed. The same applies to marine and industrial lubricants; there are professional services that will take care of and recycle them. This is not only efficient but also protects the environment. Plus, it reduces the likelihood of hazardous substances contaminating the soil or water."

Certainly, as long as they are formulated from non-toxic ingredients and have high content water with thickening agents and lubricating additive powders. They should also be easy to wash away with water, which makes them safe for the food processing industry. These lubricants help to reduce friction and wear between food processing equipment parts.

The signs that lubricant needs to be changed include: discoloration, bad smell, foaming, oil leaks, contaminated oil, sludge deposits, wear and tear of parts, heating up of the equipment, deterioration of seals, and increased operating costs. However, the best way to know for sure is through quantitative lab testing of the used oil in comparison with the critical parameters of the new oil. This considers only quality and not quantity.

The primary functions of lubricants are to reduce friction and wear, enhance energy efficiency, protect against corrosion and rust, dissipate heat, extend the life of moving parts, improve the performance and reliability of machinery, provide sealing, prevent contamination, and minimize equipment noise and vibration.

Yes, there are several environmentally friendly design lubricants available. These are primarily made out of biodegradable substances such as vegetable oils that break down naturally after some time, so they don't pollute the environment. Moreover, they're non-toxic, which means they won't harm wildlife or humans, even if they accidentally get exposed. Water-based and solids lubricants are ideal examples of green alternatives that help to conserve the environment while ensuring equipment's optimal functioning.

Waterproof grease is used to provide a barrier between moving parts and the elements. This helps prevent contaminants like dirt, dust, and water from entering mechanical systems. By creating this protective shield, the grease allows internal components to operate smoothly regardless of external conditions. When properly applied, waterproof grease extends the lifespan of machinery by reducing wear and tear caused by friction and environmental factors.