(55 products available)

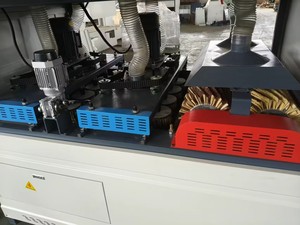

An edger sanding machine is a type of sanding machine designed to sand the edges or perimeters of wooden workpieces. It is usually smaller than a belt sander and is capable of producing high-quality finishes on wooden surfaces. Edger sanders can be differentiated based on their construction, mode of operation, and the extent of sanding they offer.

Since sanding machines represent a considerable investment and play a critical role in the production process, regular maintenance is important to ensure efficiency, optimize performance, and prolong machine life. Routine machine maintenance can help optimize output, extend the machine's lifespan, and prevent the unnecessary and costly downtime of production lines caused by frequent breakdown.

Maintenance checklist:

Edger sanding machines play an integral role in woodworking businesses and DIY workshops. They are commonly used to edge various boards, including hardwood, plywood, and particleboard. This makes them a go-to tool for carpentry enterprises that deal with hardwood products such as oak, maple, beech, cherry, walnut, and teak.

Hardwood edging is a popular application for wooden floors. When installing a hardwood floor, one needs to edge the boards to achieve a snug fit along the perimeter. Sanding machines allow installers to achieve precise edges that reduce gaps along the walls or any other obstructions. An added advantage of a perfectly edged hardwood floorboard is the uniformity throughout the floor.

In furniture making, edger sanding machines are used to give a refined finish to tabletops, headboards, and cabinet materials. Since furniture items are closely examined, precise edging becomes paramount for a first-class, appealing finish. Undesirable splinters and uneven edges are quickly and effortlessly removed using a sanding machine.

Another popular application is chamfering or beveling. Many woodworking enthusiasts and professionals use an edger to create beveled or chamfered edges on various joints. This includes joints on furniture, decks, and door frames. The sanding eliminates sharp edges and makes joints and assemblies to be cleaner, neater, and more aesthetically pleasing.

A sanding machine can also be utilized to shape and profile edges. Some sophisticated machines come with interchangeable blades that allow users to change the profile of the edges according to their preferred style. This also opens up to a myriad of applications, including molding, edging shelves, and assembling cabinets.

The following tips will help buyers to make confident purchasing decisions.

Consider the Types of Edger Sanders

Understand the features and benefits of different machines. So, buyers will confidently choose the right type to meet their specific woodwork projects.

Assess Machine Performance

Focus on key performance metrics like finish quality, sanding speed, and horsepower. Choose a machine that delivers optimal performance for the intended application.

Evaluate Build Quality

An appropriate edger sanding machine will have a strong frame, a stable platform, and durable parts like sanding belts and motors. So, it will last longer and provide reliable service.

Consider Maintenance and Servicing

A well-maintained sanding machine performs better and lasts longer. Choose a machine with easy-maintenance parts. Consider also those that come with extensive servicing support.

Assess Dust Management Systems

A good dust management system prevents dust build-up to improve machine performance and reduces health risks. So, it is good to consider the effectiveness of a machine's dust extraction system, including its compatibility with different vacuum cleaners.

Assess the Adjustable Features

Edge sanding tasks are usually different. Therefore, the machine will probably need to work on various types of wood. Choose a machine that has adjustable features, such as speed and sanding depth. It will allow operators to set the parameters to suit specific workpiece requirements.

Operator's Safety

A safe edger sanding machine minimizes the risk of accidents. So, pay attention to the machine's protective housings, emergency stop buttons, overload protection, and lock-out mechanisms. Choose a machine that has the necessary safety features.

Consider Belt and Roller Availability

Belt and roller parts are the spare parts for an edger sanding machine. Their availability will affect maintenance and servicing. Before purchasing an edger sanding machine, find out the availability of their belts and rollers.

Q1. What is the difference between an orbital sander and a detail sander?

A1. A detail sander is more compact and is designed to sand smaller areas and tight corners. It is however less powerful than an orbital sander and is not ideal for tackling large sanding jobs. An edger sanding machine takes the detail sander a step further by being more effective at sand-ing edges of woodwork and floors. The orbital sander is more suitable for general-purpose sanding and stripping tasks and is perhaps the most preferred at-home DIY projects.

Q2. How many types of sanders are there?

A2. There are eight main types of sanders, including the ones already discussed above (belt, drum, orbital, and palm sanders). The other types are the detail sander, quarter sheet sander, spindle sander, and edger sander. An edger sander is similar to a spindle sander but is specifically designed to sand edges.

Q3. Is it necessary to get a vacuum attached to the sanding machine?

A3. Sanding wood produces large amounts of dust, which can be harmful to the health of the person doing the job. While not mandatory, it is definitely recommended to have a dust extraction system. Aside from helping to keep the work area clean, vacuuming the dust helps to ensure the sanding work is as precise as can be, and the surface is perfectly leveled.