Introduction to Encoder S

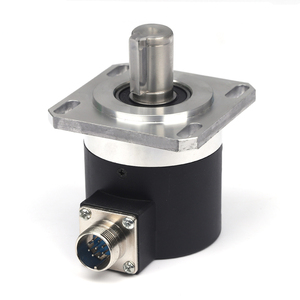

Encoder S is an essential component in various automated systems, enabling precise position and speed control. Designed to convert angular or linear motion into digital signals, Encoder S plays a pivotal role in industries such as manufacturing, robotics, and automotive. As automation becomes increasingly prevalent, the demand for Encoder S units continues to grow, providing solutions for reliable and accurate measurement.

Types of Encoder S

- Incremental Encoders:

- Provide relative position feedback based on change in position over time.

- Commonly used in motion control applications requiring precise speed measurements.

- Absolute Encoders:

- Offer specific position information within a full rotation, making them ideal for applications where position loss may occur.

- Utilized in robotics and other automation where precise control of position is critical.

- Linear Encoders:

- Measure motion along a linear path rather than rotary motion.

- Perfect for applications requiring linear measurements such as CNC machines and conveyor systems.

Applications of Encoder S

- Robotics:

- Provides feedback on the position of robotic arms and tools.

- Ensures precise movement capabilities for increased efficiency.

- Manufacturing:

- Integrated into CNC machines for accurate cutting and milling operations.

- Monitors conveyor belt speeds to enhance productivity.

- Automotive:

- Essential for electronic throttle controls and stability systems.

- Used in wheel speed sensors to enhance vehicle safety and performance.

Advantages of Using Encoder S

- Enhanced Precision:

- Delivers high-resolution outputs for exact control and measurement.

- Reduces system errors and improves overall performance.

- Robustness:

- Built to withstand harsh environments, such as extreme temperatures and vibration.

- Long lifespan with low maintenance requirements, ensuring cost-effectiveness.

- Flexibility:

- Available in a variety of styles and configurations to suit diverse applications.

- Can be customized for unique operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4