(32 products available)

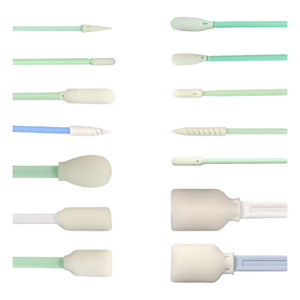

Electrostatic discharge (ESD) safe swabs are designed for sensitive electronic components. They absorb and release minimal static electricity. These swabs effectively clean circuit boards and other electronic parts without damaging them. Various types of esd safe swabs are available, depending on the intended use:

Wood ESD Swabs

Manufactured from high-quality wood, these ESD swabs are great for cleaning and applying solutions to different electronic devices. Their strong construction provides adequate support when cleaning delicate parts. The natural fiber tips are soft and absorbent, ensuring no residue is left after cleaning. Their antistatic properties minimize static discharge, making them safe for use on sensitive electronic components.

ESD Foam Swabs

These are crafted with a dense foam tip securely attached to a sturdy plastic handle. The foam material provides excellent cushioning, which is important when cleaning or applying pressure to sensitive parts. The durable plastic handle ensures the swab won't break or snap easily during use. Foam ESD swabs are widely used in the electronics industry for their versatility and reliability in preventing static damage.

ESD Cotton Swabs

These ESD swabs have a soft and absorbent cotton tip. This makes it ideal for cleaning delicate electronic components and circuit boards. The cotton material effectively removes dust, debris, and excess solder without leaving any residue. The sturdy wooden or plastic stick provides excellent control and precision during cleaning. The antistatic treatment ensures safe use in ESD-sensitive environments.

ESD Microfiber Swabs

Manufactured from fine synthetic fibers, these swabs are excellent for cleaning delicate electronic components. The microfiber material traps and lifts dust and dirt particles, leaving no residue. The fine and soft fibers ensure no scratching or damage to sensitive surfaces. The sturdy handle provides excellent control and precision during cleaning. The antistatic treatment ensures safe use in ESD-sensitive environments.

ESD Synthetic Fiber Swabs

These ESD swabs are made from durable synthetic fibers. They are designed for cleaning and applying solutions to different electronic devices. They have a strong construction that provides adequate support when cleaning delicate parts. The synthetic fiber tips are soft and absorbent, ensuring no residue is left after cleaning. They are also durable and long-lasting, making them suitable for frequent use in demanding environments.

ESD safe swabs are essential tools in sensitive electronic environments. Selecting the right kind means considering several factors. First, think about the application. Do users need the swab for cleaning intricate parts of the circuit board or for general cleaning? Foam tip swabs work well for precise cleaning, while cotton tip swabs are better for broader areas. Next, consider the material. Some ESD swabs are made from polyester, while others are made from foam or cotton. Foam is usually preferred because it does not shed and is non-abrasive, making it ideal for delicate components. However, the application may require a different material.

Another important factor is the tip of the swab. In some cases, users need to clean only a minute area, which may require a pointed tip. Some pointed ESD swabs have tapered foam tips that can be used for cleaning small nozzles, sockets, and holes. Other varieties have rounded tips that are ideal for cleaning larger areas. When choosing ESD safe swabs, it is also important to consider the handle. Some handles are ergonomic and easy to use, while others may be long and rigid. Rigid handles are ideal for niche jobs, but they may not be suitable for tasks that require frequent movement. Foam swabs with long and flexible handles are ideal for cleaning circuit boards because they can easily reach every nook and cranny.

It is also important to consider the packaging when choosing ESD swabs. Some come in bulk packaging, while others are packaged in smaller quantities. Smaller packaging makes it easy for users to access the swabs as needed. However, bulk packaging may be more economical for larger jobs or projects that require a lot of swabs. Finally, consider the ESD properties of the swabs. Look for swabs with ESD-safe materials and packaging to prevent static discharge.

Using ESD safe swabs correctly is vital to ensure they perform well and protect electronic components from static discharge. Below are steps on how to use them:

Identify the Area of Application

Determine the area where the ESD swab will be applied. ESD precision swabs with pointed tips are ideal for cleaning tight areas, while broader foam-tipped swabs can clean larger surfaces or apply lubricant or thermal paste.

Prepare the Work Area

Ensure the work area is grounded and ESD safe. Wear ESD wrist straps and work on grounded ESD mats to prevent static charge buildup. Remove any non-ESD safe items from the workspace.

Select the Appropriate Swab

Choose the right ESD swab for the job. Consider the tip material, size, and shape, and the application. For example, use a foam-tipped swab for delicate surfaces and a rigid plastic-tipped swab for rougher areas.

Ground Yourself

Before handling electronic components or devices, ground yourself by touching a grounded ESD mat or workstation. This action helps discharge any built-up static electricity safely.

Use the Swab Gently

When using the ESD swab, apply only light pressure to avoid damaging sensitive components. Clean the area in a circular motion or as required, depending on the application. If more cleaning is needed, don't twist the swab, as this may damage the component. Pull it out gently to avoid leaving residue.

Avoid Excessive Friction

Excessive friction can generate static charges that damage electronic components. If the swab becomes dirty, dispose of it and use a new one.

Dispose of Used Swabs Properly

Used ESD swabs may contain harmful substances or residues that can affect electronic components. Dispose of them in accordance with local regulations and ESD safety standards.

ESD safe swabs are essential for handling sensitive electronic components and preventing static damage. However, it is vital to follow specific product safety measures to ensure effective and safe use. First, users should always wear ESD protective gear, such as wrist straps and heel straps, to prevent static charge buildup. Grounding these items to a common point ensures maximum static dissipation. Second, ESD swabs should be stored and handled in ESD-safe environments to prevent exposure to charged materials. This practice helps maintain the swab's ESD protective qualities. Additionally, users should avoid using ESD swabs near non-ESD safe items that may generate static charges. By adhering to these safety measures, users can effectively use ESD safe swabs to protect electronic components from static damage.

Cleaning and Dusting:

Anti-static cotton swabs are used for cleaning and dusting electronic parts and components. Their small tip makes them perfect for cleaning hard-to-reach places. The soft, absorbent material at the end can remove dust or liquid.

Application of Liquids:

They can apply small amounts of oil, grease, solder, or other liquids to delicate electronic parts. The precision tip allows for controlled application without wasting too much of the liquid. This helps to reduce excess liquid that may damage electronic parts.

Testing:

They are also used to test circuit boards and electronic components. The small, pointed tip can be used to probe test points, connectors, and other areas on a circuit board. Some swabs even have a sponge-like material that can be compressed when pressed against a part for testing.

Non-ESD Safe Materials:

These swabs are made from materials that do not generate static electricity. This can include special plastics or foams that do not allow static charges to build up.

Controlled Charging:

Some ESD-safe materials are designed to allow static charges to move through the swab and into the environment instead of building up at the tip. This controlled charging helps dissipate any static safely without damaging sensitive components.

Low Charging:

Low charging materials produce very little static when rubbed together. Swabs made from low charging materials create minimal static while being used on electronic parts.

Cleanroom Compatibility:

Many ESD safe swabs can be used in cleanrooms where dust and contamination must be avoided. The materials used do not shed fibers or dust particles that could contaminate sensitive components. This makes it ideal for use in cleanrooms.

Durability:

ESD safe swabs are designed to be more durable than regular cotton swabs. This means they won't fall apart as easily when used on delicate electronic parts. This makes them more cost-effective in the long run.

Uniform Resistivity:

ESD safe swabs are designed to have a specific level of electrical resistance. This allows static charges to be safely drained without damaging sensitive components. Uniform resistivity ensures consistent performance across all swabs.

Non-Sparking Materials:

The materials used do not generate sparks when static charges are released. This is important for safe use around delicate electronic parts. Non-sparking materials help protect electronic components from damage caused by static electricity.

Moisture-Resistant Options:

Some ESD safe swabs are moisture-resistant. This feature makes them suitable for use in areas prone to slight humidity or where liquid cleaners may be used. Moisture-resistant options help protect electronic components from damage caused by moisture.

Q1. What is the difference between ESD safe and regular cotton swabs?

A1. ESD safe swabs are specifically designed for use in environments sensitive to static electricity. They are made from materials that do not generate static charges and often have non-conductive properties to prevent any static buildup or discharge that could damage electronic components. Regular cotton swabs do not have these ESD properties and, therefore, should not be used in electronic assembly or repair where static discharge is a concern.

Q2. How to properly store ESD safe swabs?

A2. Proper storage of ESD safe swabs is crucial in maintaining their effectiveness. They should be stored in a designated ESD-safe container or bag that has been treated with anti-static properties. These containers are usually fitted with foam inserts that provide additional protection and help absorb any remaining static charges. Always ensure that ESD swabs are stored in a clean, dry place, as moisture and dirt can also compromise their ESD protection. Storing them away from direct sunlight and heat sources is also a good idea, as these can degrade the anti-static properties of the swabs over time. When taking swabs out for use, always remember to ground yourself and any ESD-safe equipment properly to prevent static buildup.

Q3. Are ESD safe swabs reusable?

A3. ESD safe swabs are generally designed for single use and should not be reused. Reusing them can introduce particles and other contaminants that compromise their effectiveness in ESD protection and other cleaning applications. However, some types of ESD swabs made from durable materials can be cleaned and used multiple times, but this is not the standard for most ESD swabs.

Q4. What makes ESD safe foam swabs preferable to other types?

A4. ESD safe foam swabs have a smooth, non-porous surface that does not trap dust or particles, making them ideal for cleanroom environments. Their quality foam head ensures thorough cleaning and does not leave behind debris, which is crucial for applications in electronics where even the smallest particle can affect performance.

The web search volume for "esd safe swabs" has shown a stable trend over the past year, with an average monthly web search volume of 10. Over the last 12 months, the web search volume fluctuated between 0 and 10, with no significant change in either the three-month or one-year periods.

Analyzing the monthly data, "esd safe swabs" experienced consistent interest with peaks at 10 web searches during January, February, April, May, June, July, September, and November 2024. Conversely, there were no web searches recorded in March, August, and October of the same year. This pattern indicates a somewhat periodic interest in this keyword, possibly aligned with specific industry needs or seasonal procurement cycles.

The stability of the web search volume, despite the zero web searches in certain months, suggests a niche but persistent demand for esd safe swabs. This could imply that while the product is not in high demand, it is crucial for specific applications, likely in electronics manufacturing or related fields where electrostatic discharge safety is paramount. The lack of significant growth in web search volume might reflect market saturation or a well-understood need within a specialized sector.