Comprehensive Insight into EVA Scrap From

In the realm of materials and recycling, EVA scrap from defines the versatile remnants obtained after the production and utilization of Ethylene-Vinyl Acetate (EVA) products. This eco-friendly material, known for its excellent flexibility, durability, and light-weight properties, has a broad spectrum of applications, rendering EVA scrap a valuable resource for manufacturers and recyclers alike. Understanding the various aspects of EVA scrap can contribute significantly to waste reduction, cost savings, and sustainable practices in numerous industries.

Types of EVA Scrap From

EVA scrap is categorized based on its source, form, and quality, making it suitable for different recycling processes.

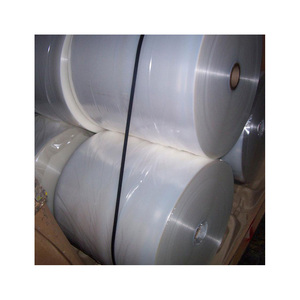

- Production Scrap: Generated during the manufacturing process of EVA products, this category includes off-cuts and trimmings.

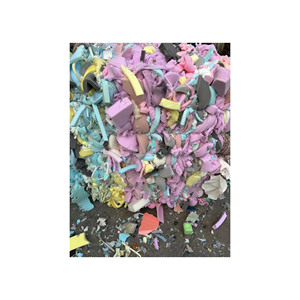

- Post-Consumer Scrap: Sourced from discarded EVA items like footwear, packaging, and toys, these scraps are collected for recycling.

- Industrial Scrap: Derived from industrial applications, this scrap often contains higher quantities of EVA material and is easier to recycle.

- Clean vs. Contaminated Scrap: Clean scrap is free from dirt and foreign materials, while contaminated scrap requires additional processing to remove impurities.

Applications of EVA Scrap From

The applicability of eva scrap from is vast and varied, catering to numerous fields and industries.

- Footwear Manufacturing: EVA scrap is repurposed to create new soles or padding for a wide range of footwear, significantly reducing production costs.

- Packing Materials: Recycled EVA scrap contributes to the production of eco-friendly packaging solutions, enhancing sustainability in the packaging sector.

- Sports Equipment: Many sports products utilize EVA for padding and shock absorption, making recycled EVA a sought-after material in the industry.

- Toys and Household Items: EVA scrap from old toys can be transformed to create new playful experiences for children, promoting a circular economy.

Advantages of Using EVA Scrap From

Utilizing eva scrap from offers numerous advantages that benefit both manufacturers and the environment.

- Cost Efficiency: Recycling EVA scrap significantly reduces material costs for manufacturers, leading to overall cost savings.

- Environmental Benefits: Using recycled EVA contributes to lower waste levels, diminishing the carbon footprint associated with new material production.

- Enhanced Material Properties: The combination of virgin and recycled EVA can result in improved product properties, such as increased flexibility and strength.

- Support for Circular Economy: Utilizing EVA scrap reinforces the idea of a circular economy, where resources are reused and waste is minimized, promoting sustainability.