Introduction to Falk Couplings

Falk couplings are a pivotal component in industrial machinery, designed to connect rotating shafts while accommodating misalignment and damping vibrations. These couplings are renowned for their robust performance in demanding environments and are widely used across various industries. With a legacy of innovation and reliability, Falk couplings ensure efficient operation and prolong the life of machinery. Understanding their features, types, and applications can help businesses make informed decisions in optimizing their operations.

Types of Falk Couplings

Falk couplings come in several designs, each tailored to specific applications and performance requirements. The primary types include:

- Fluid Couplings: Utilized primarily in scenarios requiring smooth engagement and soft starting, fluid couplings effectively transmit torque via hydraulic fluid.

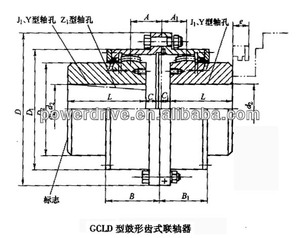

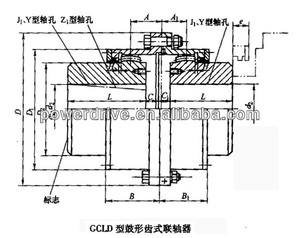

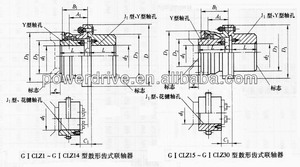

- Gear Couplings: Known for their ability to withstand high torque and provide significant angular misalignment capability, gear couplings are ideal for heavy machinery.

- Diaphragm Couplings: These couplings are effective in high-speed applications, providing flexibility with minimal backlash.

- Elastomeric Couplings: Engineered for shock absorption and vibration dampening, elastomeric couplings are favored for their lightweight and durable design.

Applications of Falk Couplings

Falk couplings find applications across a myriad of industries, thanks to their versatility and robust performance. Common applications include:

- Manufacturing Equipment: Employed in conveyors, mixers, and shredders, Falk couplings play a vital role in ensuring seamless operation.

- Mining and Quarrying: These couplings are essential for heavy-duty equipment where high torque transmission is critical for operational efficiency.

- Pumping Systems: In the hydraulic industry, Falk couplings are integral to connecting pumps with motors, ensuring reliability in fluid transport.

- Wind Energy: Used in wind turbine assemblies, Falk couplings help mitigate the stresses caused by variable loads and misalignment due to external environmental factors.

Features and Advantages of Falk Couplings

Falk couplings offer a range of features that contribute to their widespread use and popularity in various industrial applications. Key advantages include:

- High Torque Capacity: Designed to handle significant forces during operation, Falk couplings ensure that machinery performs effectively under heavy loads.

- Vibration Dampening: By reducing vibrations, Falk couplings enhance the lifespan of both the coupling and the equipment it connects.

- Misalignment Compensation: Falk couplings can accommodate angular, parallel, and axial misalignments, which helps maintain optimal performance even in imperfect conditions.

- Durable Materials: Constructed using high-quality materials, Falk couplings are engineered to withstand harsh environments and operate efficiently over extended periods.

- Easy Installation and Maintenance: The design of these couplings facilitates straightforward installation and reduces downtime, making them a favorite choice for maintenance teams.