(11913 products available)

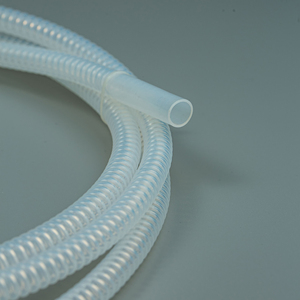

A flexible corrugated plastic tube is a type of conduit that is flexible and has a ribbed surface. It's designed to carry wires, cables, and fluids and is made from different types of materials, such as polyethylene, PVC, and polypropylene. Each material has unique characteristics that suit the tube for different applications.

The flexible corrugated plastic tubes are classified into different types based on their application. They include:

Flexible corrugated plastic tubes are commonly used in construction and electrical applications because of their light weight and flexibility. Their smooth interior surface allows for easy water flow, wire pulling, and conduit installations.

Features:

Functions:

The use of a flexible corrugated plastic tube is widely applicable in different industries and sectors. This is because it has different properties and advantages over other types of tubes. It is lightweight, flexible, and cost-effective. Here are some common usage scenarios.

Construction and Building Projects

This tube is popularly used in construction projects. It is used as a conduit for electrical wiring. Its flexibility and lightweight nature allow for easy installation in different configurations and layouts. The tube is also used for drainage purposes. It helps in the efficient and effective removal of water runoff and rainwater. This helps in preventing flooding and water accumulation in building projects. Other uses in construction include; formwork for concrete pouring, venting pipes for HVAC systems, and protecting fiber optic cables.

Landscaping and Agricultural Applications

These flexible tubes are popular in agricultural setups. They are used for irrigation systems. Their flexibility allows for easy water distribution to crops and plants. This is especially in fields with uneven terrains. They are also used for planting projects such as tree planting. In landscaping, corrugated tubes are used for edging and borders. This helps in creating a clean and defined landscape design.

Telecommunications

Flexible plastic corrugated tubes are used widely in the telecommunications industry. They are used as conduits for fiber optic and data cables. Their lightweight and flexible nature allows for easy installation in different terrains. It also facilitates the movement and delivery of high-speed internet connections and telecommunication signals.

Automotive and Transportation

The automotive industry widely uses flexible corrugated tubes. They are used for wiring harnesses. This includes the protection and management of electrical wiring in vehicles. Their flexibility allows for the routing of wires in tight spaces. This is between engine components and other electrical parts. Additionally, these tubes are used for air intake systems and fluid transfer.

HVAC Systems

Flexible HVAC ducting is made from either metal or plastic material. It is used in heating, air conditioning, and ventilation systems. Corrugated flexible plastic tubes are used to create ductwork. This allows for the distribution of air in a building or room. Their flexibility allows for easy installation in different layouts and designs. They are also lightweight and cost-effective compared to traditional ducting systems.

Application Requirements

Assess the application needs before anything else. Consider the temperature and environmental factors. Look at the fluid or gas being moved and its acidity or corrosiveness. Flexible plastic tubes for electrical work will differ from those used for plumbing.

Materials and Durability

Choose a tube material appropriate for the use case. Polyethylene is common because it's lightweight and flexible. However, it may need to be thicker for robust applications. Options like polypropylene or PVC offer varied benefits like strength or temperature resistance.

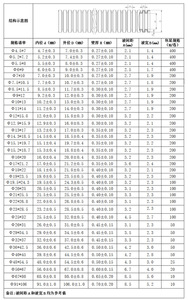

Diameter and Length

The required diameter and length of the tube will significantly impact performance. A tube needs to be adequately sized to allow for smooth fluid or gas flow without restriction. Measure the space or system into which the tube will fit.

Regulatory Compliance

Ensure the chosen flexible corrugated tubes comply with industry standards and regulations. This is critical for safety in applications like construction or medical devices. Ask suppliers for proof of compliance documentation.

Supplier Expertise and Support

Consider the level of support from the supplier. An experienced vendor can offer valuable guidance in selecting the right tube. Look for suppliers who provide technical documentation and have a solid track record.

Customization Options

If there are unique needs, check if the supplier provides custom solutions. This could include tailored lengths, diameters or additional features like reinforcement. Customization ensures the tube perfectly suits its intended purpose.

Cost Considerations

While quality should come first, the tube's cost is still significant. Balance between price and performance to find a tube that meets all needs without going over budget. Sometimes, opting for a slightly more expensive but better-quality tube is wise, considering its long-term value.

Q1: Is it possible to customize a flexible corrugated plastic tube?

A1: Yes, it is possible to customize a flexible tube. Customization options include tube length, diameter, color, and printing logos on the tube.

Q2: Which is better, a flexible or a corrugated tube?

A2: It depends on the application. Flexible tubes are ideal when minimal bending and movement are required. On the other hand, corrugated tubes are suitable for applications that need light weight and enhanced rigidity.

Q3: What are the tubes' wholesale prices?

A3: The wholesale prices vary depending on the tube type, size, material, and vendor. It is advisable to request a quotation from the vendor to get the standard price range.