Introduction to Flexible Coupling in India

Flexible couplings play a pivotal role in mechanical engineering, especially in industries focused on precision movement and connectivity between rotating shafts. As machinery continues to evolve, the demand for flexible coupling in India has surged, offering industries reliable solutions to accommodate misalignment, reduce vibration, and enhance overall efficiency. This product description aims to provide a comprehensive overview of flexible couplings, discussing their types, features, applications, and key advantages.

Types of Flexible Coupling in India

Flexible couplings are designed to connect shafts while allowing for a degree of misalignment and movement. The following are the primary types commonly used across various industries in India:

- Rubber Couplings: Utilized in applications requiring shock absorption and noise reduction, rubber couplings offer flexibility and resilience.

- Metallic Couplings: Known for their durability and strength, metallic couplings are used in high-torque applications.

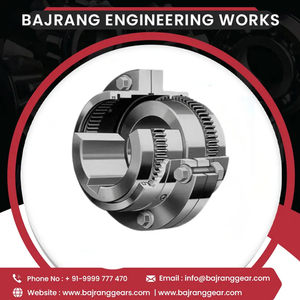

- Gear Couplings: Featuring toothed gears, these couplings are ideal for heavy-duty applications that demand high torque transmission.

- Disc Couplings: Excellent for compensating misalignment, disc couplings use thin metallic discs to connect shafts while accommodating axial movement.

- Elastomeric Couplings: These couplings utilize elastic materials to provide flexibility, reduce shock loading, and allow for moderate misalignment.

Applications of Flexible Coupling in India

The application of flexible couplings spans across a myriad of industries, showcasing their versatility and importance. Here are some key areas where flexible couplings are extensively employed:

- Manufacturing: Used in conveyor systems and machinery, flexible couplings facilitate smooth operations and accommodate component expansion.

- Pumps and Compressors: Essential for connecting pump shafts in various sectors, they minimize vibration and help maintain system integrity.

- Wind Turbines: In renewable energy applications, flexible couplings play a crucial role in connecting rotor shafts, accommodating movement and stress.

- Automotive Industry: They are pivotal in connecting drivetrains, ensuring efficient power transfer while managing misalignments.

- Textile and Food Processing: Flexible couplings ensure the smooth operation of machinery, preventing downtime and enhancing productivity.

Advantages of Flexible Coupling in India

Investing in high-quality flexible couplings offers numerous benefits that enhance operational efficiency and extend the lifespan of machinery. Here are the key advantages:

- Vibration Reduction: Flexible couplings absorb vibrations, reducing wear and tear on components.

- Alignment Compensation: They allow for misalignment between shafts without causing damage, improving the durability of the system.

- Easy Installation: Most flexible couplings are designed for straightforward installation, reducing downtime during setup.

- Maintenance-Free: Many modern flexible couplings are designed to be lubricated-free, minimizing maintenance costs and efforts.

- Versatile Material Options: Available in a variety of materials, they can be tailored to meet the specific needs of different industries, enhancing usability.