(4037 products available)

A flexible hose with valve is a plumbing component used to connect two parts of a plumbing system that need to be connected but can't be directly connected due to space issues. Flexible hoses with valves are used in various applications, such as kitchen plumbing, bathroom plumbing, and washing machine plumbing. Flexible hoses with valves are popular among manufacturers and designers because they allow for easy connections, even in tight spaces. It also reduces the risk of pipe damage during installation, as it can bend and maneuver around obstacles.

Flexible hoses with valves are not the same; each application has a unique design, size, and material. The main types of flexible hoses with valves are explained below.

Water Flexible Hose with Valve

This type of hose is used to connect water pipes to faucets or toilets. It is made with materials like stainless steel, PVC, and rubber. The size of the water flexible hose with valve will differ based on the application it's used for. For example, a faucet hose can be 20 inches long, while a toilet hose can be 12 inches long. One key feature that makes this hose popular among manufacturers is its abrasion resistance. This hose can withstand the wear and tear caused by water flow, making it last longer.

Gas Flexible Hose with Valve

As the name implies, this hose is used to connect gas appliances to gas supply lines. One striking feature that makes this hose suitable for gas appliances is its anti-explosion design. The gas flexible hose with valve has been designed to prevent any form of explosion or accidents. They are also very easy to install.

Refrigerant Flexible Hose with Valve

This type of hose is used in HVAC systems to connect different parts, such as the compressor, condenser, and evaporator. It is designed to carry refrigerants safely and efficiently. Like other flexible hoses with valves, it comes in different sizes depending on the application. For instance, a refrigerant hose for air conditioners can be 36 inches long, while for a refrigerator, it can be 24 inches long. These hoses are manufactured with materials that can handle low or high pressure. They also feature insulation to prevent condensation and improve energy efficiency.

Flexible hoses with valves are essential in plumbing systems. They allow for quick and easy connections between pipes and fixtures. These hoses and valves have different features that improve their functionality, which include:

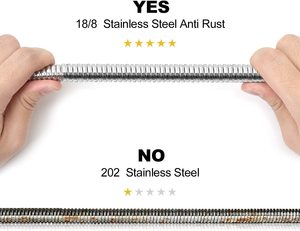

Material

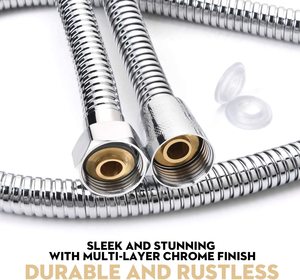

Flexible hoses with valves are made of different materials. These materials include stainless steel, rubber, plastic, or a combination of these materials. Hoses and valves made of stainless steel are very durable and corrosion-resistant. Those made of rubber are lightweight and flexible. Plastic hoses and valves are lightweight and resistant to corrosion.

Flexibility

The flexible hose with valve is designed to be bendable and flexible. This allows it to be installed in tight spaces or around obstacles. Its flexibility also helps in reducing stress on the pipeline, which prevents leaks and cracks.

Pressure rating

Pressure rating refers to the maximum pressure the hose can withstand. Flexible hoses with valves are designed to work under high-pressure conditions. They are safe to use in residential and industrial applications. These hoses and valves have a pressure rating of up to 1.6 MPA.

Temperature rating

Temperature rating is the range of temperatures within which the flexible valve and hose can operate. These hoses and valves can operate at high and low temperatures. For example, from -10 degrees to 120 degrees. Temperature rating is an important feature because extreme temperatures can damage or burst a pipe or valve.

Length and diameter

Flexible hoses with valves come in different lengths and diameters. This enables them to be used in different applications. The diameter of the hose and valve determines the flow rate. A larger diameter allows for a higher flow rate. The length of the hose allows for connections over long distances. It also reduces the need for rigid piping and connection points, which improves ease of installation.

Shut-off capability

The valve on a flexible hose allows for the control and shut-off of water flow. This enables the complete shut-off of water to a fixture for repairs or maintenance. The shut-off capability improves the safety and convenience of these hoses and valves.

Anti-twist design

Some flexible hoses and valves have an anti-twist design. This prevents the hose from twisting during installation. The anti-twist design ensures a smooth flow of water and reduces the risk of damage to the pipeline.

Flexible hoses with valves are used in various applications. These include:

Watering plants

Flexible garden hoses with in-built valves are popular among gardeners. This is because they are lightweight and easy to maneuver. The valve at the end of the hose allows the user to control the water flow. This makes it easy to water delicate plants. It also enables the user to switch between different water spray settings. This is useful for watering plants with different water needs.

Cleaning

Hoses with valves are commonly used for cleaning. They can be connected to pressure washers for cleaning driveways and patios. Some flexible pressure washer hoses have valves that allow users to adjust the water pressure. This is important for cleaning different surfaces without damaging them.

Filling containers

Flexible hoses with valves can be used to fill containers. For example, buckets, tanks, and watering cans. The valve allows precise control of the water flow. This minimizes spillage and waste. It also enables the user to fill containers with different volumes of water.

Horticulture and agriculture

Farmers and horticulturists prefer flexible hoses with valves for irrigation. The valves allow the control of water flow to different areas of the farm. This promotes water conservation and ensures uniform irrigation. Additionally, the hoses can be used with drip irrigation systems for efficient water delivery to plants.

Car washing

Washing cars using flexible hoses with valves is convenient. This is because the hoses are lightweight and easy to use. The valve allows water flow control. This minimizes water wastage. It also enables the user to rinse and wash different parts of the car effectively.

Construction

Construction workers use flexible hoses with valves for different applications. The valves control the water flow for filling forms during concrete pouring. They also control water for cleaning tools and construction sites. Additionally, these hoses can be connected to water pumps for efficient water delivery on construction sites.

Material:

Flexible water hose with valves are made from different materials like plastic (PVC), rubber, or reinforced fabric. Each has its pros and cons. For example, a flexible rubber hose with a shut off valve is more durable and weather resistant than other materials. However, it is heavier than other options. Consider the application and choose the right material.

Size and diameter:

Flexible hoses with valves come in different sizes and diameters. The right choice will depend on the amount of water to be transferred and the water pressure. When transferring water with low pressure, a larger diameter hose will work well. However, for high-pressure water, a smaller diameter pipe will be perfect. Flexible hoses with valves are also measured in inches. The size of the hose must fit the valve connection.

Temperature:

While choosing a flexible hose, check the maximum and minimum temperature the pipe can withstand. Different flexible hoses have different temperature ranges. It is important to choose one that can withstand the temperature of the liquid being transferred.

Length:

Flexible hoses are available in different lengths. While choosing a hose, consider the distance between the connection points. Ensure the right length is chosen to avoid excess material or insufficient length.

Wall thickness:

The thickness of the wall will determine the durability of the flexible hose. A thicker wall will mean more durability. Consider the application and choose the right thickness. If the application requires high pressure, then a thicker wall will be required.

Valve Type:

The valve type will determine the flow control. Different valves have different applications. The hose can be fitted with ball valves, gate valves, check valves, or globe valves. Ball valves offer quick and easy on/off flow control. They have minimal resistance when the valve is open. Globe valves are great for throttling and flow control. They have a distinctive pattern and are easy to operate. Flexible hose with check valves prevents backflow and ensures one-way flow. They are used in applications where backflow is a concern. Gate valves provide a full flow with minimal resistance. They are best suited for on/off applications where flow control is not required.

Q1. What are the key components of a valve hose?

A1. A valve hose has three main parts: a flexible hose, a valve, and fittings. The flexible hose allows for easy routing and movement. The valve controls fluid or water flow through the hose. The fittings connect the hose and valve to the source and destination securely.

Q2. What should be considered when choosing a valve pipe for a project?

A2. Consider the fluid type, working conditions, and project specifications. The fluid type determines the hose material choice for compatibility. Working conditions like temperature and pressure guide the selection of appropriately rated hoses and valves. Project specifications include the required hose length and valve type.

Q3. How can one maintain valve pipes for durability?

A3. Proper installation prevents kinks and bends that can restrict flow or cause damage. Regular inspections identify wear and tear early. Replace any damaged parts promptly. Clean the hose regularly to prevent blockages and maintain optimal flow.

Q4. What are the benefits of flexible hoses with valves?

A4. They allow for easy routing around obstacles, which is useful in complex setups. They enhance the system's versatility by accommodating different configurations and movements. Flexible hoses reduce the risk of system failure due to bends or kinks.

Q5. What's the difference between a hydraulic and a non-hydraulic valve hose?

A5. A hydraulic hose is specifically designed for high-pressure applications in hydraulic systems. It has reinforced construction and specific fittings. Non-hydraulic valve hoses are used for various applications and may not withstand high pressure.

The keyword "flexible hose with valve" maintains a consistent average monthly web search volume of 10, showing no significant change over the past year. Over the last three months, the web search volume has remained stable, with no percentage increase or decrease noted. However, a notable spike occurred in June and July 2024, where web searches temporarily doubled to 20 and then tripled to 30 respectively, before reverting to the usual volume of 10 in subsequent months.

This keyword's trend reveals a generally steady interest level, with the exception of a brief peak during the summer months. The consistent web search volume indicates a stable demand, likely driven by specific seasonal needs or projects that require the use of flexible hoses with valves. The spike in June and July could be attributed to increased gardening or home improvement activities, which are common during warmer weather.

The data suggests that while the overall demand for "flexible hose with valve" is modest, there are specific periods when interest and possibly demand increase. This pattern could be valuable for businesses in the construction and real estate sectors to align marketing or stock inventory with expected demand peaks.