(11913 products available)

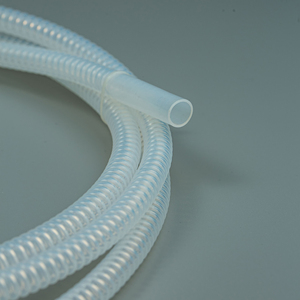

A flexible plastic corrugated tube is a type of tube made from flexible plastic that has a corrugated, or ridged, surface. It is used to carry or protect wires, cables, fluids, or other materials in a variety of applications. The tube is flexible, meaning it can bend and move without breaking, and it is corrugated, which gives it a ridged surface that makes it more sturdy and easier to grip. Flexible plastic corrugated tubes are lightweight, durable, and resistant to bending, which makes them convenient for various applications.

Flexible plastic corrugated tubes come in different types. Here are some of them:

Flexible plastic corrugated tubes are extensively used in wire protection and other applications, as mentioned above. Their features and functions are explained below:

Excellent Flexibility

Cable corrugated pipes are used in applications where tubes are required to bend around corners and obstacles without breaking or crimping. For example, in complex wiring harness installations in automotive vehicles, flexible tubes are ideal for routing wires through tight spaces and corners.

Lightweight and Easy to Handle

These tubes are lightweight, which makes them easy to handle during installation. They are also cost-effective, which makes them popular in the construction industry.

Durability and Strength

These tubes are designed to provide long-term service. They are resistant to abrasion, which protects the wires from damage. Plastic flexible corrugated tubes are made from materials that can withstand impact and external forces, which makes them a preferred option in applications like aerospace and automotive. Their corrugated structure provides extra strength and rigidity while maintaining flexibility.

Protection of Wires from Harmful Elements

Flexible wire protection tubes shield wires from external damage, which prevents wire chafing or abrasion. This helps to maintain the integrity of the wire and prevents short circuits. They also protect wires from heat, UV radiation, and chemicals. These tubes act as a barrier to prevent these elements from causing wire degradation or overheating. For instance, in industrial settings, corrugated tubes can shield wires from hot surfaces or splashes of corrosive chemicals.

Fluid and Air Flow

Flexible plastic corrugated tubes are used in HVAC systems for air and fluid transport. Their smooth inner walls allow efficient air and fluid flow. These tubes are also used in applications such as drainage and plumbing systems.

Enhanced Aesthetics

These tubes are used in wire management to enhance the overall appearance of a system. For example, in home theaters and office setups, flexible plastic corrugated tubes can hide wiring while allowing optimal performance. They can be routed along baseboards or walls without making them look like eyesores.

Flexible plastic corrugated tubes have different applications. Some are listed below;

Material Resistance:

It's crucial to evaluate the resistance of flexible corrugated tubes to various elements before buying. Consider tubes crafted from materials like PVC, polypropylene, and polyethylene, which offer awesome flexibility and durability.

Temperature and weather conditions:

Consider the tube's capability to face up to temperature extremes and climatic conditions.

For example, if the tube is wanted for an application exposed to sunlight, consult a cloth that could resist UV rays.

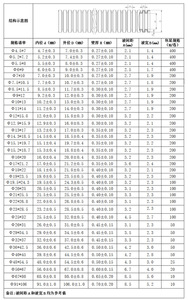

Diameter and length:

Buyers have to take into account the precise diameter and length of their tube required to suit a particular utility or mission. The flexible plastic corrugated tubes are available in distinctive diameters and lengths ranging from small to large, suitable for diverse purposes.

Applications:

It's vital to consider the tube's compatibility with unique programs. For example, some tubes are suitable for drainage, electric wiring, and plumbing, whilst others are greater applicable for agricultural uses.

Buyers' needs:

Before purchasing any flexible tubes, it is important to determine the needs, such as the budget, unique requirements, and preferred characteristics. This will help ensure the tube is suitable for the intended use.

Consulting experts:

Consider seeking recommendation from professionals within the subject who can provide beneficial insights and suggestions based totally on their understanding and the specific conditions.

Quality and certification:

It is crucial to check the quality of the flexible tube and any applicable certifications to ensure it meets the required standards and is suitable for the intended application.

Q1: What are flexible plastic corrugated tubes used for?

A1: These tubes are used for wiring protection in construction, automotive, HVAC systems, and drainage.

Q2: Are flexible plastic corrugated tubes durable?

A2: Yes, they are durable, and the materials used in making them are long-lasting and capable of withstanding harsh conditions.

Q3: Can tubes be recycled?

A3: Most materials used in making flexible corrugated tubes are recyclable. This includes LDPE, HDPE, and polypropylene.

Q4: Are the flexible plastic corrugated tubes customizable?

A4: Yes, the tubes are customizable. They come in various sizes, lengths, colors, and diameters. Customization also includes adding markings and logos on the tube.

Q5: What are the common types of flexible plastic corrugated tubes?

A5: The common types include; non-perforated and perforated plastic corrugated tubes. The other classification is based on material, which includes; polyethylene, polypropylene, and PVC corrugated tubes.