(42972 products available)

Form rollers are specialized tools used in metalworking and fabrication processes to create curved and cylindrical shapes from flat metal sheets or strips. These machines are essential for producing a wide range of metal components with consistent and accurate curves, such as pipes, tubes, rails, and architectural profiles. Here are some key types of form rollers:

Horizontal Form Roller

The horizontal form roller is a metal-shaping tool widely used in industries such as metalworking, construction, and manufacturing to create curved and circular shapes from flat metal sheets or strips. This machine is particularly useful for producing items like pipes, tubes, rails, and architectural profiles. The horizontal form roller consists of three main rollers arranged in a horizontal plane. The top roller is adjustable and serves as the pressing roller, while the bottom two rollers act as the forming rollers. The metal sheet is fed through the rollers, and as it passes between them, it is gradually shaped into a curve or circle. The horizontal configuration allows for easy loading and unloading of materials, making it efficient for larger sheets and thicker materials. One of the key advantages of the horizontal form roller is its precision and consistency. By maintaining a constant pressure and speed, the machine produces uniform curves with minimal distortion or stretch of the metal. This is essential for applications where the integrity of the weld or joint is critical, such as in piping systems or structural components.

Vertical Form Roller

The vertical form roller is a metal-shaping tool used to create curved and circular shapes from flat metal sheets or strips. This machine is widely used in industries such as metalworking, manufacturing, and construction to produce items like pipes, tubes, rails, and architectural profiles. The vertical form roller consists of three main rollers arranged in a vertical plane. The top roller is adjustable and serves as the pressing roller, while the bottom two rollers act as the forming rollers. The metal sheet is fed through the rollers, and as it passes between them, it is gradually shaped into a curve or circle. The vertical configuration allows for easy handling of materials, making it efficient for larger sheets and thicker materials. One of the key advantages of the vertical form roller is its precision and consistency. By maintaining a constant pressure and speed, the machine produces uniform curves with minimal distortion or stretch of the metal. This is essential for applications where the integrity of the weld or joint is critical, such as in piping systems or structural components.

Roller Forming Machine

Roller forming machines are industrial equipment used to shape and mold materials, typically metal sheets or strips, into specific profiles or curves. This process is widely used in manufacturing various products, including pipes, tubes, gutters, railings, and other custom metal profiles. The principle behind roller-forming machines involves feeding a flat strip of material through a series of rollers, which gradually shape the material into the desired profile. The rollers are precisely calibrated and can be adjusted to create different shapes and curves. There are several types of roller-forming machines, including rotary and stationary ones. Rotary roller-forming machines use rotating rollers to shape the material continuously, while stationary machines have fixed rollers and move the material through them. Another differentiation can be made between the machine types based on their end products. Some machines are designed specifically for circular profiles, such as pipes and tubes, while others create open profiles, like C- and Z-profiles.

These tools are versatile and can be used in different applications and industries. Here are some common applications:

Business owners should consider the following factors when purchasing;

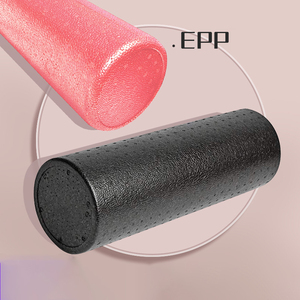

Material

Mattress rollers' materials determine their durability and performance. Therefore, buyers should choose materials that are firm and well-built. For instance, those made with EVA, PE, and polyurethane are beneficial since they are strong and offer a firm surface. In addition to this, it's essential to consider the material of the machine components. Steel and aluminum are the best choice for the form roller machine shafts and bearings since they are wear-resistant and sturdy.

Adjustability and Customization

Business owners should get machines that allow them to adjust the pressure and temperature. Such adjustments offer customized services depending on the client's needs. Also, purchase machines that can allow the addition of different roller types. This is beneficial since different roller types can provide distinct massage benefits.

Size and Portability

The size of form rollers affects their usage and storage. In this case, buyers should get compact machines that are portable and easy to store. Also, such machines are ideal for businesses whose customers value convenience and mobility.

Ease of Use and Maintenance

The form roller machine should be easy to operate. More importantly, it should have user-friendly controls and interfaces. Additionally, business owners should choose machines whose maintenance requirements are minimal.

Heat Function

As discussed earlier, some machines have a heating function. The heating function is useful since it helps to relax and warm the muscles. This results in improved muscle recovery.

Noise Level

In most cases, people use form rollers in quiet environments. Therefore, it is important to consider the noise level produced by the machine. More importantly, purchase machines constructed with materials that minimize vibrations and noise.

Cost and Value

Before purchasing, business owners should evaluate the machine's cost and the value it offers. Although premium machines are expensive, they offer better features and durability. Therefore, buyers should get machines that strike a balance between cost, quality, and functionality.

Improved Muscle Recovery

These tools are essential in exercise and physical activity as they enhance muscle recovery. They do this by decreasing soreness and inflammation, which can lead to faster recovery times. Muscle recovery is often delayed after intense workouts or physical activity. This tool helps reduce this downtime, allowing individuals to return to their training or physical activity more quickly.

Enhanced Flexibility

These rollers are also useful when trying to improve one's flexibility. This is especially true for athletes who need to have a wide range of motion in their muscles and joints. They achieve this by helping to loosen tight muscles and fascia, which increases the elasticity of muscles. Furthermore, they can help target specific areas that may be too tight, such as the hamstrings, calves, and hip flexors.

Deep Tissue Massage

The primary feature of the Form roller is to provide a deep tissue massage, which is necessary for self-myofascial release. This technique is essential for loosening muscle knots and decreasing muscle tension and stiffness. Thanks to its unique design, the Form roller can deliver concentrated pressure to specific points in the body. This pressure is very helpful in breaking up adhesions and improving blood circulation in the muscles.

Customizable Pressure

Most of these rollers provide customizable pressure; this option is necessary for individuals who have certain preferences when it comes to the intensity of massages. This is because they can adjust the pressure to suit their needs. The ability to customize the pressure is made possible by the removable inserts or adjustable rollers.

Portable and Lightweight

These foam rollers are portable and lightweight, making them easy to carry around and store. Most of them are designed to fit into gym bags or backpacks; this ensures that individuals can use them anywhere and anytime.

Ergonomic Shape

The form roller's ergonomic shape is necessary to provide optimal pressure and support. This design targets specific muscles and areas, such as the back, neck, and legs. The shape also helps to balance and stability, which is important for achieving the right pressure during the massage.

Q1: What is the appropriate frequency for using a Form roller?

A1: Users can use foam rollers in their daily activities, primarily if they work out regularly. They are excellent tools for reducing muscle tension and soreness and improving one's flexibility and, most importantly, lowering one's risk of injury.

Q2: What is the perfect way to clean a Form roller?

A2: Cleaning the rollers is as simple as using a damp cloth with mild soap. Ensure they dry completely before storing them. This technique will keep them hygienic and in good shape.

Q3: Can someone use a Form roller on all body parts?

A3: Absolutely! One can use a Form roller on any body part, particularly on the back, butt, thighs, and calves. Nevertheless, when using them on sensitive areas, such as the lower back or joints, one should exercise caution and be gentle.

Q4: Is it possible for someone not to use a Form roller after working out?

A4: One can use a Form roller anytime, whether before or after working out, or even both. Rolling out muscles helps increase blood flow and warmth, which prepares muscles for exercise. On the other hand, when used after exercising, it reduces inflammation and muscle soreness.