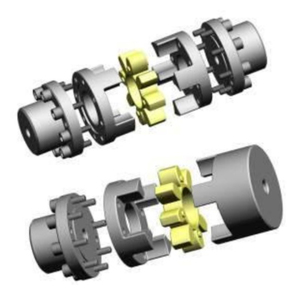

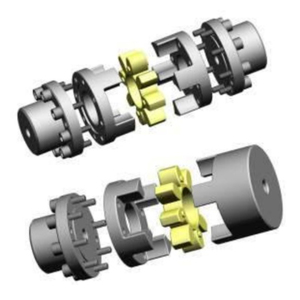

Introduction to GR Type Coupling

The GR type coupling is an essential component in various industrial applications, often serving as the link between rotating shafts in a mechanical system. Renowned for their robust design and reliable performance, GR type couplings are favored in industries where precision and durability are critical. Their ability to accommodate misalignment while transmitting torque makes them a go-to choice for engineers and designers aiming to ensure operational efficiency and longevity.

Types of GR Type Couplings

Understanding the different types of GR type couplings can help in selecting the right one for specific applications. Here are the primary varieties:

- Rigid Couplings: These couplings are designed to connect two shafts directly, providing maximum torque transfer without flexing.

- Flexible Couplings: Suitable for applications where slight misalignment is present. They can handle angular, parallel, and axial misalignments.

- Active Couplings: These are engineered for torque adjustment, allowing the user to fine-tune performance as needed.

- Interlocking Couplings: Designed with teeth or projections that interlock, providing a secure connection that can handle higher torque loads.

Applications of GR Type Couplings

The versatility of GR type couplings facilitates their use in a multitude of settings. Here are some common applications:

- Machinery: Used in various machinery setups, including conveyors, pumps, and compressors.

- Agriculture: Employed in tractors and farming equipment for shaft connections, enhancing operability under challenging conditions.

- Automotive: Utilized in different automotive components for maintaining effective power transmission between parts.

- Manufacturing: Critical in assembly lines and robotic systems, ensuring precise movements and synchronization.

Features, Materials, and Advantages of GR Type Couplings

One of the defining aspects of GR type couplings is their notable features and material composition that collectively contribute to their reliability and efficiency:

- Durability: Made with high-quality materials such as stainless steel, aluminum, or bronze, ensuring longevity even in harsh environments.

- Flexibility: Capable of absorbing shocks and vibrations, thus safeguarding connected machinery from damage.

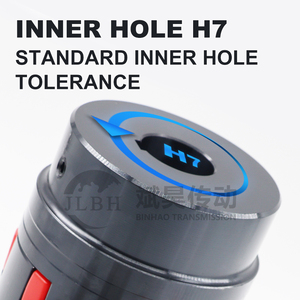

- Ease of Installation: Designed for straightforward installation, GR type couplings minimize downtime and maximize productivity.

- Cost-Effectiveness: Their long life cycle translates into reduced maintenance and replacement costs, providing excellent value over time.