(1079 products available)

Generally, a chiller is a type of machine that takes heat out of a liquid through a vapor-compression or absorption process. Gree chillers are industrial-sized cooling devices designed to remove heat from a building or provide process cooling in industrial applications. They work by circulating a refrigerant that absorbs heat from the environment or the process being cooled.

Gree offers a wide variety of chillers with different refrigerants and compressor types. Here are some examples:

System Configuration:

Familiarize with the chiller's setup, whether it's air-cooled or water-cooled, along with its specific components like the condenser, evaporator, compressor, etc.

Operating Parameters:

Regularly check the working temperatures and pressures of key components to ensure they are within their specified ranges. Gree air cool chillers typically operate with a condensing temperature between X and Y degrees and an evaporating temperature between A and B degrees. The refrigerant pressure should also be checked to ensure it is within the specified normal range.

Lubrication System:

Users should keep the oil level of the compressor within the specified range and select the proper lubricant according to the requirements. Regularly inspect and maintain the lubrication system to ensure good oil flow and performance.

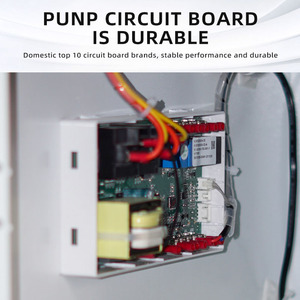

Electrical System:

Check the electrical components, such as the contactor, relay, etc., to ensure good connection and normal operation. Regularly inspect the power supply system to avoid problems and ensure stable power supply.

Protection Devices:

Regularly check the protection devices, such as thermal overload relays, pressure controllers, etc., to ensure their normal operation and good condition. These protection devices can promptly detect faults and protect the chiller accordingly.

Cleaning and Maintenance:

Clean the condensers and evaporators of the Gree chillers regularly to remove dirt and dust on their surfaces to ensure good heat exchange performance.

Office buildings

Gree air cool chillers are ideal for maintaining a comfortable working environment in office buildings. They provide cool indoor temperatures to enhance employee productivity, focus, and general well-being.

Hotels and restaurants

Restaurants benefit from Gree chillers that offer guests a comfortable atmosphere. In addition, hotels use Gree chillers for popular areas like ballrooms, restaurants, and banquet halls.

Industrial manufacturing

A variety of businesses can benefit from Gree chillers. For instance, the refrigerant chillers can be used in food and beverage processing facilities to ensure product integrity during processing, packaging, and storage. Additionally, Gree chillers can help maintain optimal temperatures for sensitive materials, preventing degradation or spoilage in pharmaceutical and chemical manufacturing facilities.

Data centers

Data centers use Gree chillers to keep critical IT equipment like servers and networking devices at an ideal temperature. Gree chillers also help avoid system downtimes and electronic device failures caused by high temperatures.

Shopping malls

Shopping malls use Gree chillers to provide cool indoor spaces for visitors. The chillers improve visitors' shopping experience by maintaining comfortable temperatures throughout the mall.

Hospitals and healthcare facilities

Hospitals use Gree chillers to ensure that patients receive a comfortable indoor environment. Furthermore, the chillers help regulate temperatures in operating rooms, patient rooms, and laboratories.

Several factors need to be taken into account before selecting Gree chiller products.

Application demands analysis

To choose the right chillers, users need to analyze the specific demands of their applications. Consider factors such as the chilled medium (typically air or water), heat load (temperature and amount of heat), cooling capacity required, temperature range, pressure requirements, and operating environment (temperature, humidity, etc.)).

Chiller types

Based on the application needs, users can select the appropriate chiller type. If the user needs to provide large amounts of chilled water, centralized cooling is required. An air-cooled or water-cooled screw/centrifugal cold machine is recommended. For small amounts of chilled water, an air-cooled/fully enclosed cold machine is optional. For large heat loads, ice storage machines are better. If the user needs to cool the refrigerant, a low-temperature chiller is recommended.

Energy efficiency and operation cost

Look at the energy efficiency of the chiller, such as the coefficient of performance (COP) or energy efficiency ratio (EER). Higher energy efficiency can reduce energy consumption and operating costs.

Noise requirements

If a user is to install a chiller in a place where noise is critical, it should consider the machine's noise level and choose a suitable noise-reduction model or noise-reduction measures.

Space constraints

The user needs to consider factors like cooling capacity, the type of machine room, and installation space and choose a chiller that fits the available space.

Product reliability and brand

To select a reliable and high-performing product, users should refer to the reputation and reliability of different brands in the market and consider factors like after-sales service and technical support.

Q1: Are air-cooled chillers more popular than water-cooled ones?

A1: Yes, air-cooled chillers are generally more popular than their water-cooled counterparts. Their simpler installation process, reduced requirement for auxiliary cooling towers, and lower risk of bacterial growth due to lesser water use make them preferred choices for a myriad of applications.

Q2: Do GREE chillers use environmentally friendly refrigerants?

A2: Many GREE chiller products adopt environmentally friendly refrigerants such as R-410A to meet international environmental standards and sustainable development needs.

Q3: How long can GREE chillers work?

A3: The lifespan of a GREE chiller can vary depending on factors like maintenance, usage intensity, and operating environment. However, if properly maintained, GREE chillers can typically operate for 10-15 years or even longer.

Q4: What is the difference between a chiller and a cooler?

A4: The term "cooler" is often used to describe small, portable devices used to keep items cold, such as ice chests. Chilllers, on the other hand, are large industrial machines designed to provide constant, controlled cooling for complex systems and large spaces.