(1512 products available)

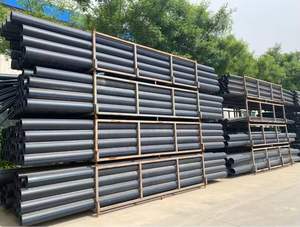

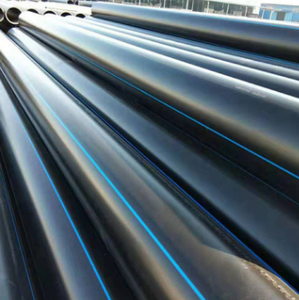

An HDPE tube 63mm is made of high-density polyethylene (HDPE), a thermoplastic material widely used in different industries due to its durability, flexibility, and resistance to chemicals and moisture. These tubes have multiple applications, including construction, agriculture, packaging, and manufacturing. They are used to transfer fluids, create protective casings, and form components in different machinery and equipment.

HDPE material is popular for making these pipes because it is lightweight, making the tubes easy to handle and install. The smooth inner surface of the tube allows for fast fluid flow, and the chemical properties of the HDPE material prevent chemical reactions with the fluid inside the tube. The 63mm HDPE tube is popular in the agricultural sector and is used for irrigation systems and water supply. It is also used in the construction industry for drainage systems and electrical conduit.

These tubes come in different sizes, from 20mm to 710mm, and are categorized based on their application or standardization.

Based on Application:

These tubes are used in different industries and applications. The construction HDPE pipe 63mm is used in construction sites for drainage systems or sewage disposal. In construction, the tubes are utilized to transport water, sewage, and other fluids. The agricultural HDPE tube is used in the agricultural sector for irrigation systems and water supply. The electrical conduit tube is a non-metallic conduit and is used to protect and route electrical wiring.

Based on Standardization:

HDPE tubes are classified based on applications, but they can also be categorized according to standardization. These include SDR (standard dimensional ratio) and IPS (iron pipe size). SDR is a method used to determine the relationship between the diameter of the pipe and the thickness of the pipe. In most cases, the lower the SDR number, the thicker the pipe wall. The thickness of the wall increases the pressure capacity of the pipe. IPS size refers to a system of measurement using inches. An HDPE tube 63mm will have an IPS size of 2.5 inches.

HDPE pipes are commonly used in construction and engineering projects. They are also used in different contexts, such as civil and agricultural, and have many other uses. The functions of these pipes are quite interesting. Let's take a look at some of them in detail:

HDPE plastic pipes are used in fluid transportation. These tubes are used in the transportation of fluids such as water, sewage, and chemicals. This is because they are corrosion-resistant, and they have a smooth inner surface that allows for easy fluid flow.

The HDPE tubes 63mm are also used for cable management. These tubes protect electrical cables and conduits from damage and environmental factors. The tubes shield these cables from damage and ensure their longevity.

HDPE pipes are also used for drainage systems. These tubes provide efficient and reliable drainage solutions for stormwater runoff, agricultural drainage, and wastewater disposal. Their flexibility and durability make them ideal for drainage applications.

These tubes come with different features. Let's look at some of their key features.

63mm HDPE pipes are used in various applications because of their excellent properties. These pipes are lightweight, resistant to impact, and highly durable. Here are some applications of HDPE tubes 63mm:

Conduits for electrical cables

HDPE pipes are used in many applications to protect electrical cables. Their smooth inner walls reduce friction and make cable pulling easy. Their flexibility allows them to be installed in areas without being damaged during bending. These pipes are also resistant to chemicals and moisture, which protects cables from potential damage and ensures their integrity.

Water supply pipes

HDPE tubes are also used in water supply systems. Their strength ensures they resist water pressure, and their smooth inner walls ensure a steady water flow. These pipes are also corrosion-resistant, which ensures they deliver clean water without contamination.

Irrigation

63mm HDPE pipes are also used in irrigation systems. Their flexibility allows them to be installed in areas without being damaged during bending. These pipes ensure uniform water distribution to crops, increasing agricultural productivity.

Drainage pipes

HDPE pipes are used in agricultural and residential drainage systems. Their strength ensures they can withstand the weight of the surrounding material. These pipes are also resistant to abrasion, ensuring they last longer and reducing the need for constant replacement. Additionally, their smooth inner walls ensure a steady flow of water.

Underground cable conduits

Many industries use 63mm HDPE pipes as conduits to house and protect underground cables. Their strength ensures they can withstand impact and prevent cable damage. These pipes are also resistant to UV radiation, increasing their popularity. Additionally, they are lightweight, which makes them easy to transport and install.

Mining

In the mining industry, HDPE pipes are used to transport slurries, water, and other liquids. Their flexibility allows them to be installed in challenging terrain without breaking. These pipes are also resistant to chemicals and corrosion, ensuring they are ideal for mining applications.

When looking at different kinds of 63mm HDPE pipes for sale, it is essential to consider some factors before making a purchase. Here is a list of some key points to remember:

Q1. What are the benefits of using an HDPE tube 63mm?

A1. 63mm HDPE tubes are lightweight, making them easy to handle and transport. They are also flexible, which allows them to bend without breaking. Additionally, they are corrosion-resistant and have a long lifespan. These tubes are also cost-effective.

Q2. What are the limitations of HDPE tubes?

A2. Although HDPE tubes have many advantages, they come with some limitations. For example, these tubes are not suitable for carrying fluids at very high temperatures. They also have a low level of UV radiation. When exposed to UV radiation for a long time, HDPE becomes brittle and cracks.

Q3. How does the manufacturing process of HDPE tubes work?

A3. The manufacturing process involves extrusion, which is melting and molding polyethylene into a tube shape. The molten polyethylene is passed through a die with the desired tube size. Once cooled, the tube is cut into the required lengths.

Q4. Can someone recycle HDPE tubes?

A4. The answer is yes. HDPE is one of the most recyclable plastics. During recycling, the used HDPE tubes are first sorted, cleaned, and then shredded into small pieces. The shredded pieces are then melted and molded into pellets, which can be used to manufacture other HDPE products.

Q5. What are the common applications of HDPE tubes?

A5. HDPE tubes are used in various applications, including construction, drainage, and irrigation. They are also used in the telecommunication and electrical industries to manufacture cable sheathing. In the medical industry, HDPE tubes are used to manufacture containers and bottles.