(9919 products available)

Ready to Ship

Ready to Ship

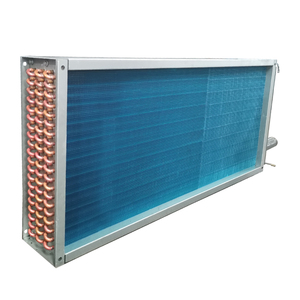

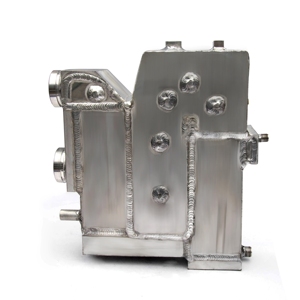

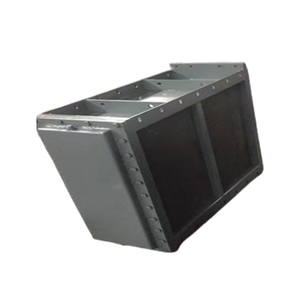

A heat exchanger is an engineering device that transforms thermal energy between two or more fluids. There are several types of industrial heat exchangers used in power plants:

The main usage of heat exchangers in a power plant is to facilitate the transfer of heat between two fluids. Exchangers' designs and uses vary according to the type of power plant they are in.

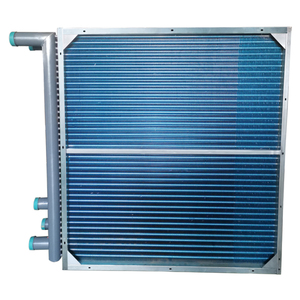

Cooling water systems

Freshwater is usually heated when it passes through the condenser of a thermal power plant. A heat exchanger is used to transfer the heat from the condenser to the cooling water. The cooling water then flows back to the river or lake. In this case, the heat exchanger prevents the cooling water from getting too hot.

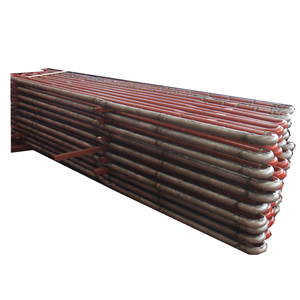

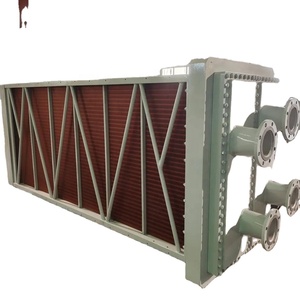

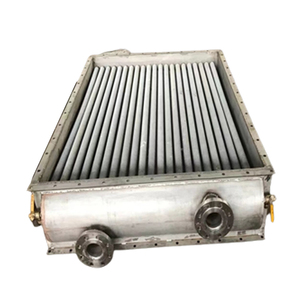

Superheaters and economizers

In a steam power plant, heat exchangers are used to heat the steam flowing to the turbine. They are located in the boiler and are called superheaters. Superheaters can raise the temperature and pressure of steam by a few hundred degrees. An economizer is a different type of heat exchanger found in a power plant. It is usually found in the boiler like a superheater. Its work is to use the heat from flue gas to heat the water coming into the boiler.

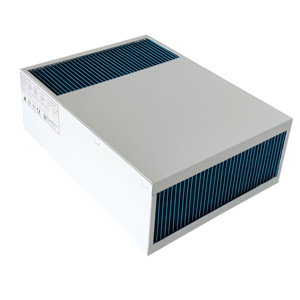

Air-to-air heat exchangers

At some points in a power plant, it may be necessary to separate the two gases. This could be to avoid contamination or for safety reasons. An example is heat exchangers between flue gas and combustion air. In this case, heat is transferred from flue gas to combustion air. Heat exchangers can be used to recover heat from flue gas and use it to heat incoming air used for combustion.

Gas turbine power plants

In a gas turbine power plant, heat exchangers can be used in a combined cycle. In a combined cycle, power is first generated using a gas turbine. Some of the heat generated in the gas turbine is transferred to a heat exchanger. The heat exchanger is then used to generate steam for power generation using a steam turbine.

Heat exchangers play a crucial role in power generation. The following tips may help buyers identify the heat exchangers suitable for their power plants:

Assess Media Properties

Consider the properties of both the hot and cold fluids. Look out for the pressure and temperature ranges, flow rates, and chemical properties (corrosive, toxic, or hazardous) of the fluids. Also, consider if the fluids are gases, liquids, or slurries. Then, choose a heat exchanger design that can handle their specific requirements.

Consider the Space Constraints

Determine the physical dimensions (length, width, and height) of the heat exchanger that will fit in the power plant. Also, consider the layout of the plant. Then, choose a compact heat exchanger design, such as plate or shell-and-tube models, if there are space constraints.

Evaluate Maintenance Requirements

Choose a heat exchanger that has low maintenance requirements if the power plant location makes it difficult to carry out regular maintenance. Consider reliable designs like shell-and-tube units. Ensure the selected heat exchanger also has accessible components for easy service and checks.

Account for Budget Constraints

When deciding on a heat exchanger for a power plant, the budget is an important consideration. Set a budget for the acquisition and installation of the heat exchanger. Then, prioritize spending on units that will enhance the performance of the power plant. Consider the long-term costs (energy and maintenance expenses) of the heat exchanger and not just the upfront purchase price.

Q1. What are the trends in the heat exchanger market?

A1. According to market reports, the global heat exchanger market size was valued at $25.92 billion in 2021 and is projected to reach $39.34 billion by 2031, registering a CAGR of 4.5% from 2022 to 2031. Some of the key trends include compact heat exchanger power plants, smart heat exchangers, and sustainable heat exchangers.

Q2. What are the differences between the condensers and heaters in power plants heat exchangers?

A2. The function of a condenser is to remove heat from a vapor and change it into a liquid. It also releases heat to the cooling medium, usually water or air. The heater, on the other hand, receives heat from a hot fluid that is usually from a boiler. It passes the heat to another fluid that is usually water that is used for heating.

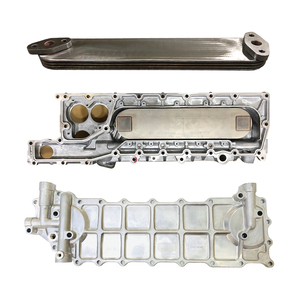

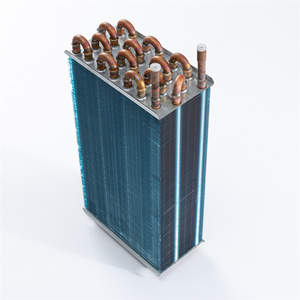

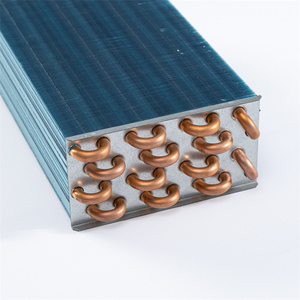

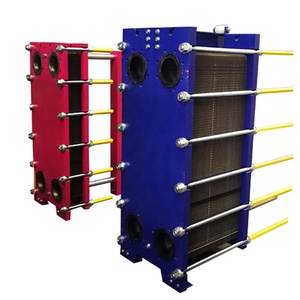

Q3. What is the difference between plate and tube heat exchangers?

A3. Plate heat exchangers are mainly used in plumbing applications while tube heat exchangers are mainly used in industrial applications. Tubular heat exchangers also take up more space compared to compact plate heat exchangers. Heat exchangers can be classified into counterflow, crossflow, and shell tube which are mainly used in power plant industries.