(28748 products available)

A high flow filter is a type of filtration device used to remove particles and contaminants from fluids while allowing a higher flow rate than standard filters. They are used in various applications, such as air filtration, liquid filtration, and industrial processes, where maintaining a high flow rate is necessary. High-flow filters use advanced materials and designs to achieve efficient filtration without significantly restricting the flow path.

High-flow filters are available in various types and configurations, each designed to meet specific filtration requirements and application needs. Here are some standard high-flow filter types:

High-Flow Liquid Filters

High-flow liquid filters are designed to remove particles and contaminants from liquids in industrial and commercial applications. They offer high flow rates and extended filter life. High-flow liquid filters come in different types, including:

High-Flow Air Filters

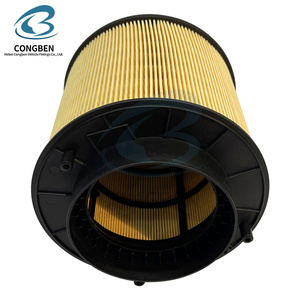

High-flow air filters are designed to improve airflow and filtration efficiency in applications such as automotive performance, industrial air handling, and HVAC systems. They use advanced filter media and construction techniques to achieve high flow rates while maintaining effective particle and contaminant removal.

High-Flow Membrane Filters

High-flow membrane filters use membranes with high permeability to selectively remove particles and contaminants from liquids and gases. The membranes are made of high-strength polymeric materials, which offer high flow rates and excellent filtration performance. High-flow membrane filters are often used in applications that require sterile filtration, such as pharmaceuticals, biotechnology, and food processing.

High-Flow Dust Collector Filters

High-flow dust collector filters are used in dust collection systems to capture airborne particles and dust while maintaining a high airflow rate through the filtering system. They are designed with advanced filter media, such as pleated cartridges, which provide a larger surface area for enhanced dust collection efficiency and reduced pressure drop. High-flow dust collector filters improve dust collection efficiency, prolong filter life, and reduce energy consumption in industrial settings.

The specifications of a high-flow filter vary depending on the application it is designed for and the manufacturer's design. Here are some general specifications that visually exemplify the differences between standard filters and high-flow filters:

It is crucial to maintain high-flow filters properly. Doing so ensures optimal performance in various applications, including water filtration, air filtration, oil filtration, and chemical processing. Here are some general guidelines for maintaining high-flow filters:

Choosing the right high-flow filter can be quite a challenge, especially with the multiple options available in the market. Here are some key considerations to help make the process easier:

Application

Consider the application for which the high-flow filter is required. Is it for air, water, fuel, or oil? Different applications have different requirements in terms of filtration efficiency and flow rate. For instance, high-flow air filters are ideal for performance enthusiasts looking to improve engine efficiency, while high-flow fuel filters are suitable for vehicles requiring better fuel delivery.

Compatibility

Ensure that the high-flow filter is compatible with the system it will be installed in. Consider factors such as size, micron rating, and flow rate to ensure optimal performance and longevity of the filter and the system it is installed in.

Quality and reliability

Quality and reliability are key considerations when choosing a high-flow filter. Look for filters from reputable brands that are known for their quality and reliability. Reading reviews from other customers can help give an insight into the quality and reliability of the filter being considered.

Price

Price is an important consideration when choosing a high-flow filter, but it should not be the only factor. Filters that are too cheap may not offer the quality and performance needed, while those that are expensive may not always be the best. It is important to consider the quality, performance, and value for money when choosing a high-flow filter.

Maintenance and ease of installation

Consider the maintenance requirements of the high-flow filter and how easy it is to install. Some filters require more frequent cleaning or replacement than others. If the filter is difficult to install, it may need to be installed by a professional, adding to the overall cost.

The DIY process of replacing a high-flow air filter is quite simple. Generally, manufacturers provide detailed instructions on how to replace the filters. Here are some general steps that can be followed to replace a high-flow air filter.

Q1: What is a high flow filter?

A1: High flow filters are designed to improve airflow into the engine, potentially increasing horsepower and torque compared to standard filters. They achieve this by utilizing superior filter media and less restrictive filtering elements that allow more air to pass through while still capturing contaminants.

Q2: How do high flow filters work?

A2: High-flow air filters use advanced filtering materials that allow more air to pass through while still capturing particles. Materials like synthetic fibers or multilayered structures strike a balance between airflow and filtration efficiency. Less restrictive designs, such as pleated elements that reduce resistance, contribute to increased airflow.

Q3: Do high flow air filters increase horsepower?

A3: While results can vary depending on the vehicle and other factors, high-flow air filters have the potential to increase horsepower slightly. By improving airflow into the engine, they may contribute to better throttle response and marginal gains in power output. The extent of any horsepower increase is generally modest.

Q4: What are the benefits of high flow filters?

A4: Benefits High-flow air filters can improve engine performance, potentially leading to better fuel efficiency, increased power output, and enhanced acceleration. They are also more environmentally friendly because they reduce the number of traditional paper filters disposed of. High-flow filters can save money in the long run because they are reusable and washable, requiring less frequent replacement.

Q5: Are high flow filters good?

A5: High-flow air filters can be advantageous in many situations, particularly for those seeking improved engine performance. They enhance airflow, potentially resulting in slightly better throttle response and marginal power gains. The long-lasting and reusable nature of high-flow filters provides cost savings over time.