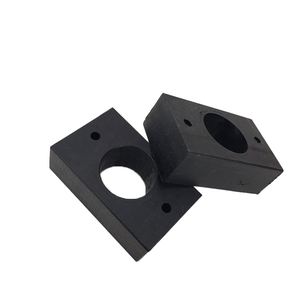

Introduction to High Quality Elastomeric Bearings

High quality elastomeric bearings are essential components in the construction and engineering sectors, particularly in structures that require flexibility and support against various stresses. These bearings are designed using advanced elastomeric materials, which offer superior performance, durability, and resilience. Their primary role is to accommodate movements due to thermal expansion, seismic activity, or vibrations while minimizing the transfer of loads and forces between structural elements.

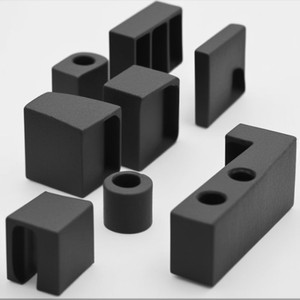

Types of High Quality Elastomeric Bearings

Elastomeric bearings can be categorized into several types based on their design and application:

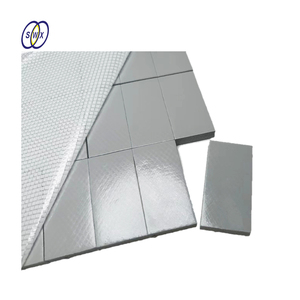

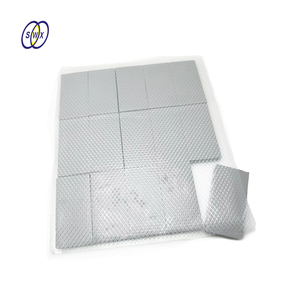

- Flat Bearings: These bearings consist of a simple layer of elastomer that allows for both horizontal and vertical movements.

- Preslated Bearings: They're designed with pre-defined slopes to facilitate drainage and reduce moisture accumulation.

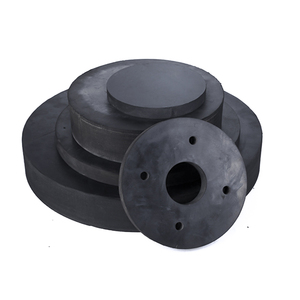

- Pot Bearings: This type comprises a cylindrical pot filled with elastomer, designed to carry high loads while permitting rotational movements.

- Spherical Bearings: These bearings allow for angular rotations while simultaneously transferring vertical loads, perfect for bridges and buildings.

-

Applications of High Quality Elastomeric Bearings

High quality elastomeric bearings find extensive applications across various industries:

- Bridges: Used to accommodate movement and reduce stress in bridge structures, enabling resilience against environmental factors.

- High-Rise Buildings: Essential in skyscrapers to manage building movements in response to winds and seismic activity.

- Transport Infrastructure: Applied in roads and rail systems to enhance ride quality and support structural flexibility.

- Parking Structures: Utilized to allow for differential movements in multi-storey car parks while maintaining overall stability.

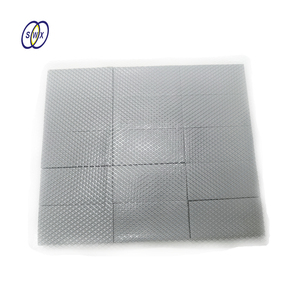

Features and Advantages of High Quality Elastomeric Bearings

High quality elastomeric bearings boast several noteworthy features and advantages that contribute to their popularity:

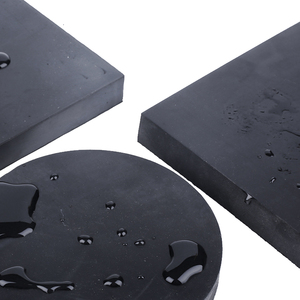

- Durability: Made from high-grade elastomeric materials, they have excellent resistance to weathering, ageing, and wear.

- Flexibility: Designed to accommodate various types of movements, including horizontal, vertical, and rotational adjustments.

- Shock Absorption: Their inherent elasticity enables them to absorb and dampen vibrations, enhancing the comfort and safety of structures.

- Low Maintenance: High quality elastomeric bearings are designed for longevity and require minimal maintenance throughout their lifespan.

- Cost-Effectiveness: Their efficiency and longer service life contribute to lower overall costs in construction and maintenance.

How to Choose High Quality Elastomeric Bearings

Selecting the right high quality elastomeric bearings involves considering various factors for optimal performance:

- Load Requirements: Analyze the expected loads and select bearings that can handle them safely.

- Movement Type: Determine the kind of movements the structure will undergo to select appropriate bearing types.

- Environmental Conditions: Consider external conditions such as temperature, humidity, and exposure to chemicals that can affect bearing performance.

- Installation Location: Evaluate whether the bearings will be used indoors or outdoors and choose materials that suit the environment.

- Compliance Standards: Ensure that the selected bearings meet relevant industry standards and regulations for safety and performance.