(485 products available)

Ice cream water chillers are cooling machines for water or other liquids to maintain low temperatures. They are integral to the production phase of ice cream before the mixture is solidified into a creamy, desirable texture. Different types of chillers exist to provide cooling solutions to varying industrial needs.

Reciprocal Chillers:

Reciprocal chillers work by boosting the pressure of the water to a level where it can maintain the desired temperature to cool down the ice cream mix. They are designed with certain key components, such as a floating piston, a drive crank, a cylinder, and a pressure seal, which all work to ensure the even cooling of ice cream mixture. They are excellent for large businesses to use because they can easily cool down large quantities of liquid. One downside, however, is that they can be a bit loud when they're working. This could be distracting in places where people are often present.

Screw Chillers:

Screw chillers utilize the operation of screw compressors to cool ice cream water. They are designed with two helical screws rotating on common axes. The first screw takes in incoming ice cream water from the evaporator. It also pushes the liquid forward in the system. The second one gets the water from the first one and then pulls its own liquid forward toward the compressor. After the water has been compressed sufficiently, it is released toward the condenser, where it cools the ice cream water. Additionally, because of their simple design and a few, easy-to-Care-for parts, they are also very simple to maintain and take care of.

Air-Cooled Chillers:

As the name suggests, air-cooled chillers use air to remove heat from the refrigerant and then cool down the ice cream water in the process. This is done by fans blowing air over a coil that contains the refrigerant. The heat is transferred from the water to the refrigerant in the coil, and at the same time, the air releases cools the refrigerant, taking in the heat. Once the heat transfer has been completed, the water is now cooled, and the refrigerant has been heated. These types of machines are great for areas that have high ambient air cool temperatures.

Cooling capacity

This capacity is usually indicated in Watts (W) or kilowatts (kW) and reflects the amount of heat the chiller can remove from the ice cream mix to maintain a specific temperature.

Temperature range

Water chillers operate within a certain temperature range, which determines the temperature that can be achieved and maintained. Generally, the temperature range of an ice cream water chiller is -5°C to 0°C.

Chilling method

Some chillers utilize water as the primary refrigerant, while others rely on air. Ice cream water chillers use chilled water to extract heat from the ice cream mixture, while air coolers rely on the flow of air to remove heat.

Dimensions and weight

These factors will influence the installation and storage space requirements of the chiller. Additionally, its weight will impact transportation and installation requirements.

Energy efficiency

Operating ice cream water chillers consume a lot of energy, which can significantly increase operating costs. Hence, selecting water chillers with high energy efficiency is essential.

To ensure its stable operation and longevity, an ice cream water chiller requires regular maintenance.

Check coolant levels and top up if necessary.

Coolant is the substance responsible for heat transfer in a chiller. Keeping the right level of coolant helps ensure the chiller's effective cooling. Regularly inspect the chiller's coolant level and surface to check for leaks. If the level is low, consult a professional to top it up.

Keep the condenser clean and free from dust.

The role of the condenser is to dissipate heat, and its performance affects that of the entire chiller. Dust and dirt can clog the condenser, thereby affecting heat dissipation. Use a soft brush or vacuum cleaner to remove the dust and dirt on the condenser regularly.

Regularly change the portable ice water cooling liquid.

Over time, the portable ice water cooling liquid can become dirty and lose its cooling performance. Regularly changing the cooling liquid can help maintain its cooling performance.

Ice cream chillers have different applications in the food industry. They are designed to keep ice cream and other frozen products cold and are commonly found in retail stores, restaurants, and ice cream factories.

Ice cream water chillers are essential machines for ice cream manufacturers. The machine continuously circulates cold water around the ice cream mix tanks. The icy water prevents the mix from getting warm so that it does not spoil. Keeping the mix cold is also important for the ice cream to have the right texture when it is blended and processed.

Ice cream water chillers are also helpful in ice cream shops. Customers can visit the shop and choose their favorites from a variety of flavors. Some customers prefer their ice cream to be extra firm. An ice cream chiller can help firm up the ice cream further before serving. This will meet the customers' demands and improve customer satisfaction, resulting in increased sales.

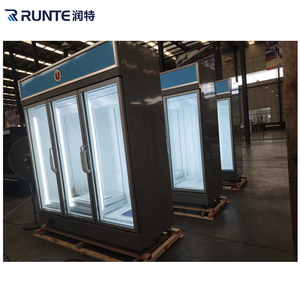

Retail stores selling ice cream products need constant refrigeration to keep their stock fresh. An ice cream cooler can help display ice cream products to customers while keeping them cold at all times.

In restaurants, ice cream chillers can be used to store and display ice cream products offered as desserts. Some machines come with a dispenser, making it easy to serve ice cream to customers without making a mess.

Mobile ice cream vendors sell their products in different outdoor settings. An ice cream water chiller can help them keep their stock cold while on the move or when working in an area without access to electricity.

Ice cream water chillers are essential tools for multiple businesses like restaurants, cafes, and diners. When selecting an ice cream water chiller to buy, restaurant owners should consider these factors:

Q1: Why must ice cream products withstand high temperatures during transportation and storage?

A1: To preserve product quality. Avoid frequent product refreezing and shopping.

Q2: Are there portable ice chillers suitable outdoor events?

A2: Yes, some portable ice chillers can suit outdoor events and temporary installations.

Q3: Can business get customized ice chillers to match their brand?

A3: Yes, many manufacturers allow businesses to get customized ice chillers to match their brand.

Q4: Can ice cream water chiller impact product marketing?

A4: Yes, how a product is stored can greatly influence its marketability. Products that can maintain high standards are likely to market better.

Q5: Can Ice Cream Chillers be used for other products?

A5: Yes, some Ice Coolers are versatile and can be used to chill a variety of products including beverages and perishable goods.