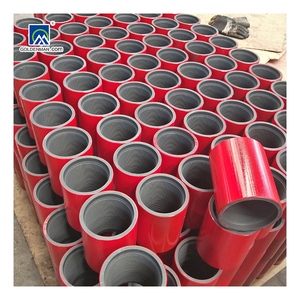

Introduction to J55 EUE Coupling

The J55 EUE coupling is a paramount component in the oil and gas industry, utilized primarily for its exceptional performance in the connection of pipe threads. Designed to cater to the rigorous demands of drilling and production environments, J55 EUE (External Upset End) couplings are known for their reliability and durability. This comprehensive description will traverse the various types, functions and features, scenarios, and safety aspects of the J55 EUE coupling.

Types of J55 EUE Coupling

J55 EUE couplings come in various configurations to meet divergent operational needs. Understanding the types available can assist businesses in making an informed choice:

- Standard EUE Coupling: Typically used for a wide range of applications, this coupling adheres to standard dimensions and mechanical properties.

- Heavy-Duty EUE Coupling: Specifically designed for high-stress environments, these couplings have enhanced resistance to tensile and compressive forces.

- Corrosion-Resistant EUE Coupling: Made with special coatings or alloyed materials to ensure longevity in corrosive environments.

- Non-Magnetic EUE Coupling: Ideal for sensitive applications like geophysical measurements, reducing interference from magnetic fields.

Function and Features of J55 EUE Coupling

The primary function of the J55 EUE coupling is to create a secure connection between drill pipes, ensuring the efficient transmission of force and fluid through the wellbore. Here are the notable features:

- High Strength: Manufactured from durable steel, ensuring the coupling can withstand high-pressure conditions.

- Interchangeability: Designed to be compatible with various other EUE threading systems, promoting ease of procurement and replacement.

- Precision Engineering: Each coupling is crafted to exact specifications, ensuring tight sealing, and preventing fluid leakages.

- Rugged Design: Built to endure harsh drilling conditions, including extreme temperatures and the presence of corrosive substances.

Scenarios for Using J55 EUE Coupling

J55 EUE couplings find application in several scenarios, ranging from offshore drilling to onshore oil production. Here are some prevalent scenarios:

- Oil and Gas Exploration: Commonly utilized in drilling operations for extracting oil and gas from underground reserves.

- Land Development Projects: Integral in supporting construction operations where deep foundations are required.

- Water Well Drilling: Used in drilling for freshwater sources, benefiting agriculture and municipal applications.

- Geothermal Energy Projects: Essential for the drilling processes involved in harnessing geothermal energy sources.

Safety and Quality of J55 EUE Couplings

Ensuring safety and product quality is paramount when utilizing J55 EUE couplings. Consider the following factors:

- Quality Control: Always source couplings that undergo rigorous quality inspections ensuring compliance with industry standards.

- Material Integrity: J55 EUE couplings should be manufactured from high-grade steel and subjected to tests for tensile strength and resistance to wear.

- Proper Maintenance: Regular inspections and appropriate maintenance practices help prevent failures and extend the lifespan of the couplings.

- Manufacturer Credentials: Partner with reputable suppliers who provide detailed certifications regarding the quality and compliance of their products.